A novel method of 3D printing patient-specific organ models has been proposed in a paper recently published in Medical Physics journal. In place of conventional open-source slicing software Nikiforos Okkalidis, a researcher at the University of Malta, proposes a pixel-by-pixel image analysis approach that works with medical standard DICOM images to create a 3D printable model.

Patient-specific medical models

Patient-specific models are proving to be a highly lucrative area for 3D printing in medicine. In recent years, additive manufacturing giant 3D Systems has been reportedly involved in over 100,000 medical cases relying on the technology and, as a result, the company has set up its On Demand Anatomical Modeling service.

In Belgium, software and 3D printing service provider Materialise’s most recent financial results were reportedly driven by the strong performance of its medical division. And there is seemingly a rise in the number of life-critical operations turning to 3D printing as a solution.

Phantoms are a subcategory of medical models that are used to control quality of diagnostic imaging equipment, student training, and determining a dose of radiation applied to an organ for cancer treatment. 3D printing is making phantoms of organs or body parts more realistic.

Pixel-by-pixel CT analysis

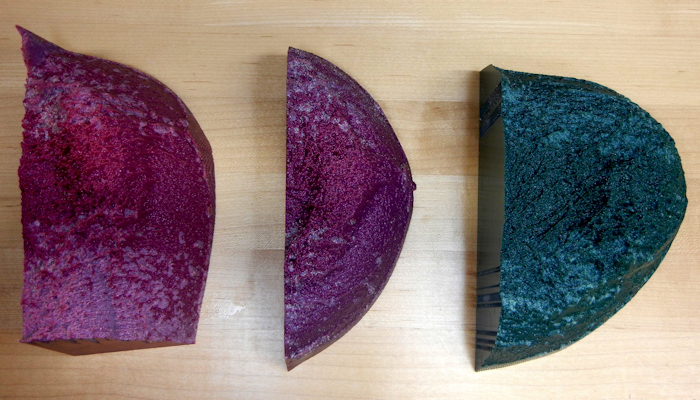

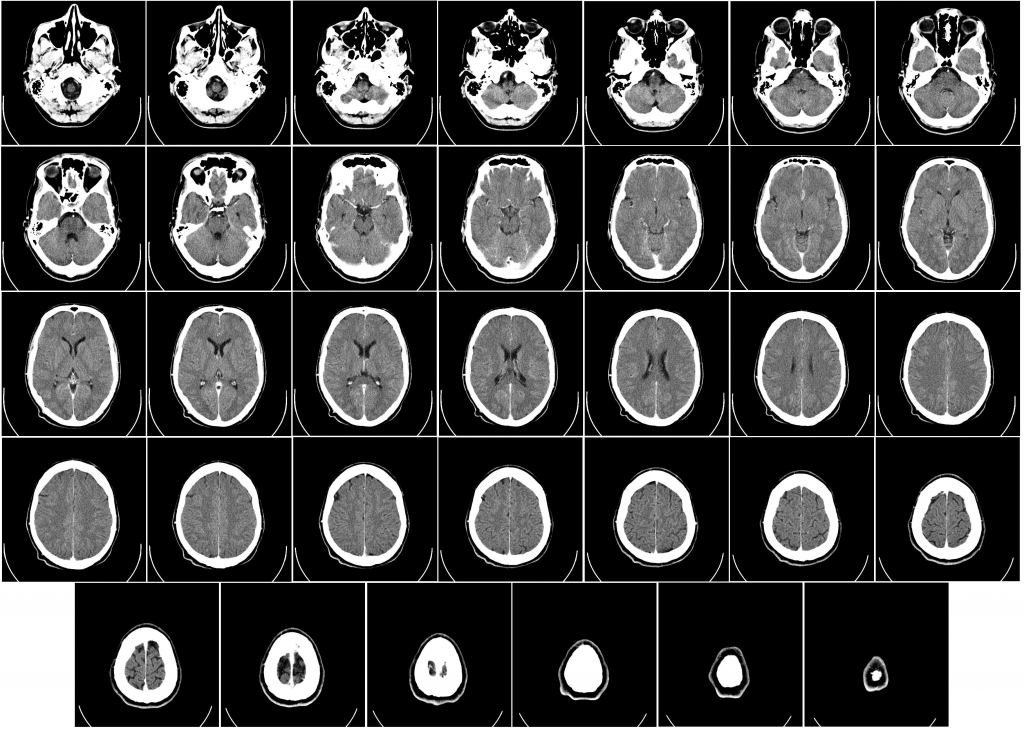

The first step in Okkalidis’ proposal for making 3D printed phantoms, is to conduct a pixel-by-pixel analysis of CT scan images to create a digital 3D model.

The pixel-by-pixel analysis in this case reads information about the radiodensity of a CT scan, i.e. the Hounsfield Units of the image. Through an algorithm, the radiodensity is correlated with the infill density of the phantom to be 3D printed, telling the 3D printer how much material should be extruded at each point of the object.

Accordingly, with this method there is firstly “no need for manual

contouring and 3D modelling of a patient’s organs.” Secondly, the 3D printed phantoms had a “wider density range” than those made without employing the algorithm. And, perhaps most significant of all, the pixel-by-pixel 3D printed phantoms:

“clearly indicated a significant improvement both visually and in the phantom [Houndsfield Unit] values achieved.”

As a result, Okkalidis is now planning to increase the methods’ accuracy, the speed of 3D printing, and conduct clinical applications with the phantoms.

Direct 3D printing from CT scans

A patented pixel-by-pixel approach to processing and 3D printing medical models, has previously been explored through a collaboration between MIT’s Mediated Matter Lab and the Wyss Institute for Biologically Inspired Engineering at Harvard University.

An artificially intelligent (AI) program for 3D printing organ models is also under development at California biotechnology company Aether.

Such solutions present doctors with a much needed streamlined workflow for 3D printing medical models directly from CT/MRI scan data.

Okkalidis’ full study, “A novel 3D printing method for accurate anatomy replication in patient specific phantoms” is available online in Medical Physics journal.

Keep up with the latest medical 3D printing news by subscribing to the 3D Printing Industry newsletter, Also, follow us on Twitter, and like us on Facebook.

Are you searching for new talent or seeking a career change? Search and post 3D Printing Jobs for opportunities and new talent across engineering, marketing, sales and more.

Featured image shows CT scan imagery of a human brain. Image via Mikael Häggström/Department of Radiology, Uppsala University Hospital. Unrelated to the work of Nikiforos Okkalidis.