A collaboration between MIT’s Mediated Matter Lab and the Wyss Institute for Biologically Inspired Engineering at Harvard University has yielded an image processing method that makes 3D printing patient-specific medical models a cinch.

While accurate, and ready-sliced for 3D printing, manually processing MRI and CT scan data is a laborious process, typically done over the course of 30+ hours.

Instead, by adopting a pixel-by-pixel approach, the MIT/Harvard team have succeeded in processing MRI and CT data in less than hour, and used it to 3D print accurate, multimaterial models of human anatomy.

Crunching big data for 3D printing has never been so easy.

Pixel-by-pixel, layer-by-layer

The MRI/CT processing project works with a related method patented by Neri Oxman, director of Mediated Matter at MIT, and colleagues Dominik Kolb, James Weaver and Christoph Bader.

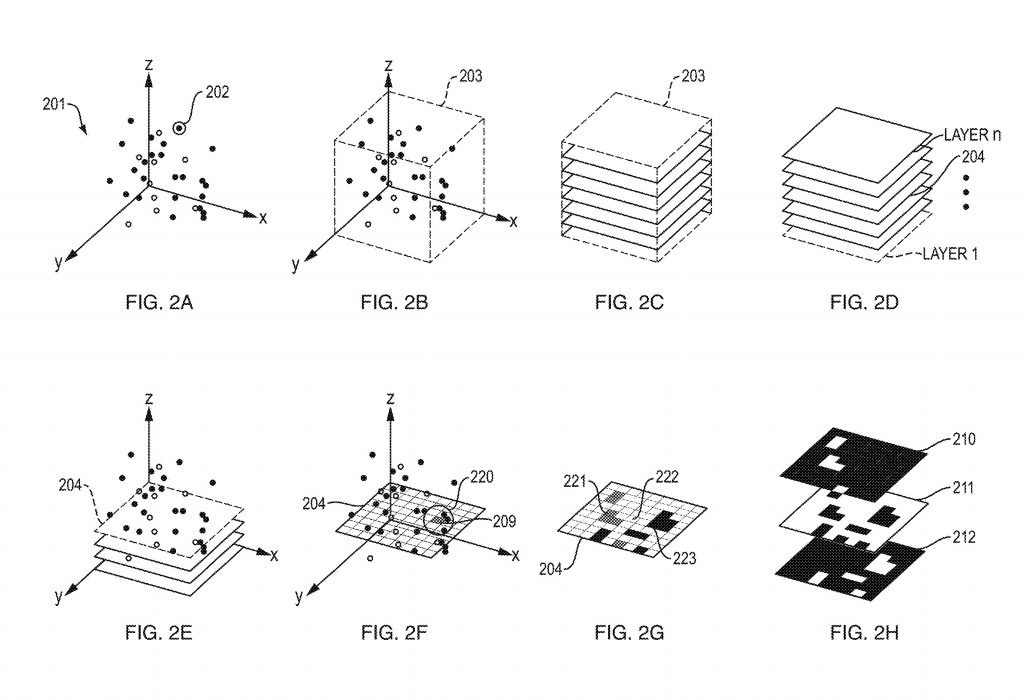

Initially described as a workflow for multimaterial 3D printing directly from point-cloud data, this method is capable of converting images into a series of detailed bitmap layers that serve as the “slices” of a 3D printable object.

The bitmap images consist of a series of black and white pixels that dictate the multilateral composition of each layer, i.e. black is a soft material, white is rigid. 3D printed on a microscopic scale, these pixels and layers combine to create varying “shades” of a material between hard and soft, preserving the detail of the original image this is processed. As an example, a hard area, like bone, would contain more white pixels, and a flexible area, like an artery, would contain more black pixels.

Empowering patients in the next 5 years

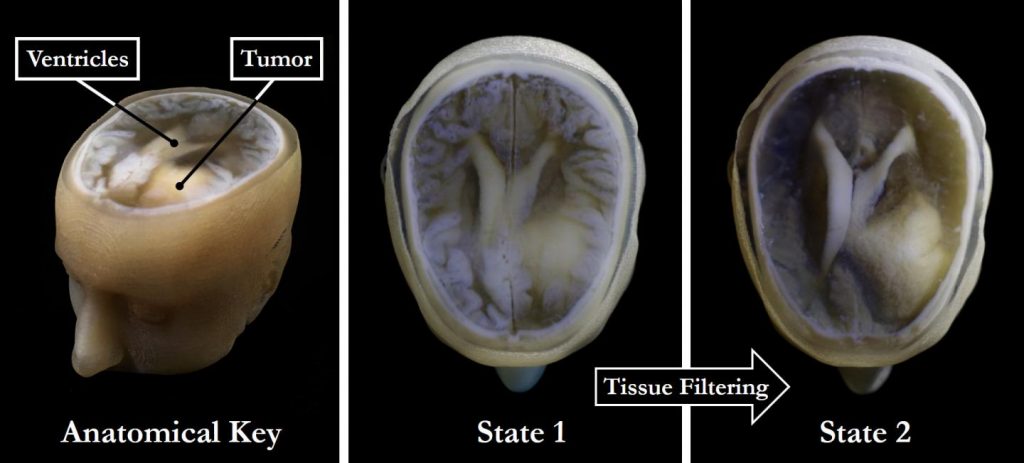

The first real-life case study of the method was conducted for Mediated Matter research affiliate Steven Keating. Finding a tumor on his brain while studying at MIT, Keating initiated the collaboration by approaching the Wyss Institute for help in understanding his diagnosis.

As a result, Keating now has a highly-detailed, multimaterial 3D printed model of his brain, and the tumor inside it. “The ability to understand what’s happening inside of you,” he says, “to actually hold it in your hands and see the effects of treatment, is incredibly empowering.”

Wyss Institute senior researcher James Weaver who worked on the project explains, “Our approach not only allows for high levels of detail to be preserved and printed into medical models, but it also saves a tremendous amount of time and money.”

With these savings, the team hopes to change the way practitioners communicate with patients. Weaver adds:

“I imagine that sometime within the next 5 years, the day could come when any patient that goes into a doctor’s office for a routine or non-routine CT or MRI scan will be able to get a 3D-printed model of their patient-specific data within a few days.”

A study on the method, “From Improved Diagnostics to Presurgical Planning: High-Resolution Functionally Graded Multimaterial 3D Printing of Biomedical Tomographic Data Sets,” is published online in 3D Printing and Additive Manufacturing journal. It is co-authored by Ahmed Hosny, Steven J. Keating, Joshua D. Dilley, Beth Ripley, Tatiana Kelil, Steve Pieper, Dominik Kolb, Christoph Bader, Anne-Marie Pobloth, Molly Griffin, Reza Nezafat, Georg Duda, Ennio A. Chiocca, James R. Stone, James S. Michaelson, Mason N. Dean, Neri Oxman, and James C. Weaver.

Subscribe to the 3D Printing Industry newsletter, follow us on Twitter and like us on Facebook for all the latest cutting edge research.

Post and find new 3D printing jobs near you now.

Featured image shows an annotated, 3D printed model of brain tumor using MIT/Harvard pixel processing. Image via Wyss Institute at Harvard University