Sutrue, a UK-based medical technology company, has debuted its new 3D printed automated suturing devices at The Design Museum, London. 3D Printing Industry attended the launch to learn more about how additive manufacturing is shaping the future of medicine.

Medical stitching (suturing) has been done by hand for over 5000 years, causing numerous needlestick injuries and diseases and time-consuming procedures. Sutrue hopes to address these issues with its two new innovations; the handheld and robotic automated suturing devices. The medical devices increase suturing accuracy, reduce the risk of injuries and diseases, and could potentially save the NHS an estimated £10.7 million each year.

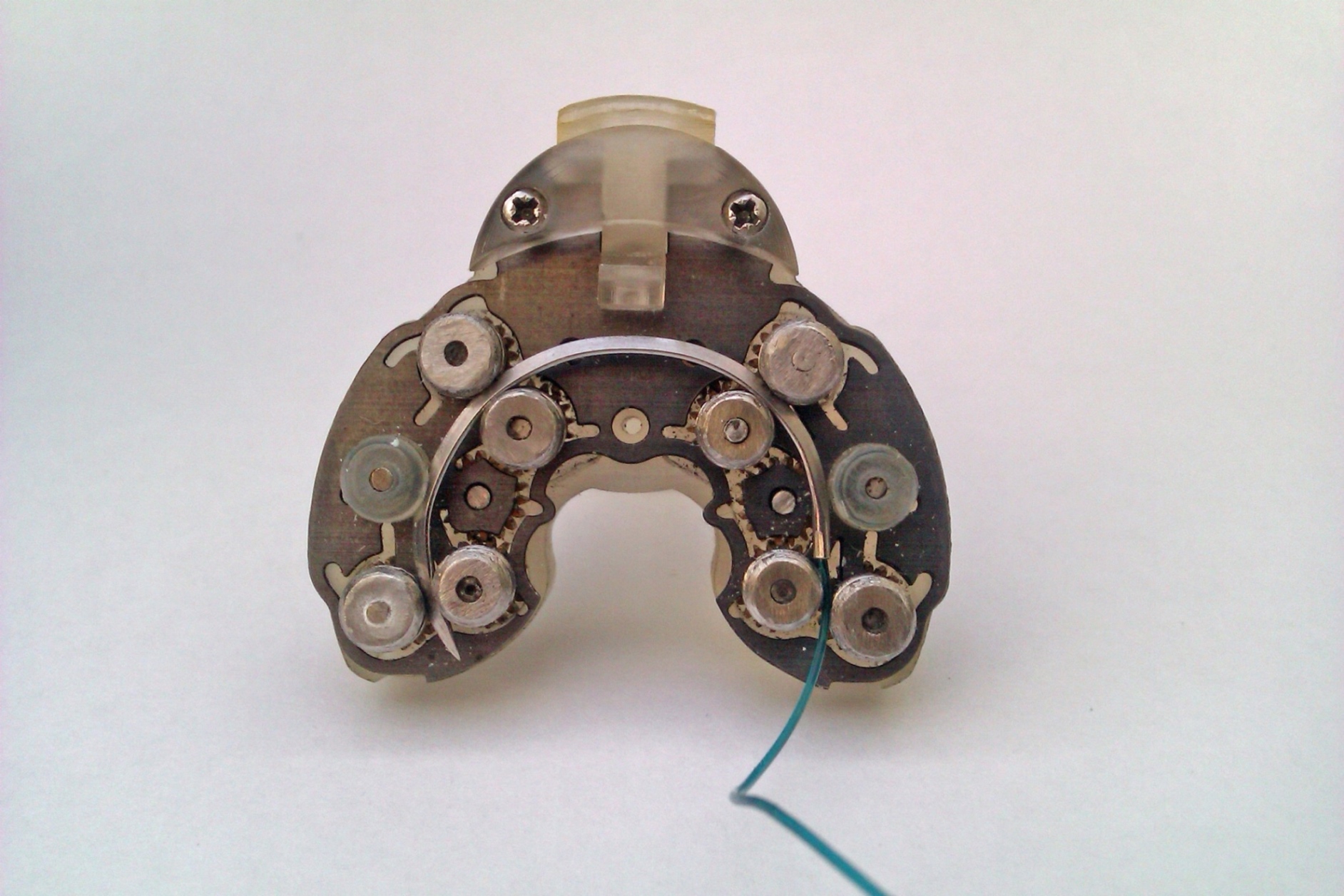

Alexander Berry, Sutrue founder, and Director explained that an intricate metal 3D printed gear mechanism operates the needle of both devices.

GE Additive streamlines production

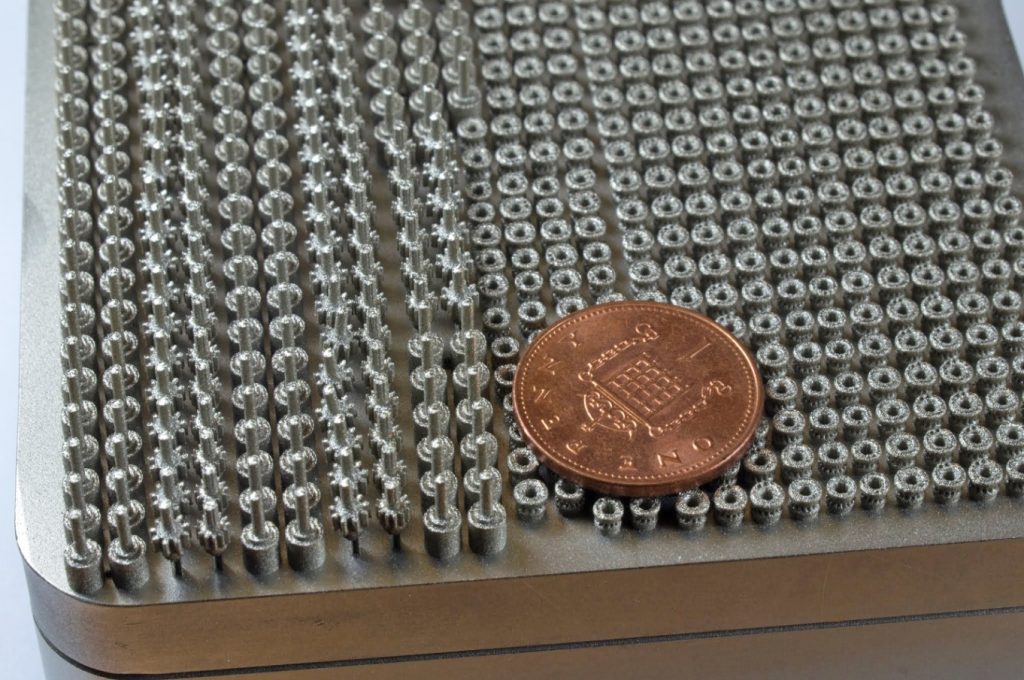

The metal gears in the Suture devices are 250 microns in length, while the tooth of an individual gear is 400 microns, boasting a higher level of accuracy within production. The medical devices were 3D printed by ES Technology using Concept Laser MLab Cusing additive manufacturing systems.

Berry explained to guests at the Design Museum that, “Without the help from GE and Concept Laser, we would have spent years going back and forth during prototype development. That’s the advantage of 3D printing – its speculative which allows us to fail during the development of our products.”

The Sutrue founder then went on to emphasize that using a MLab Cusing metal 3D printer during the engineering process allowed rapid production of 38 prototypes for the automated suturing devices.

Stephan Zeidler, Business Development Manager in the medical sector at Concept Laser told me, “We were happy to help Sutrue on their journey to improve healthcare. 3D printing is already established with many medical companies so this was nothing new for us.”

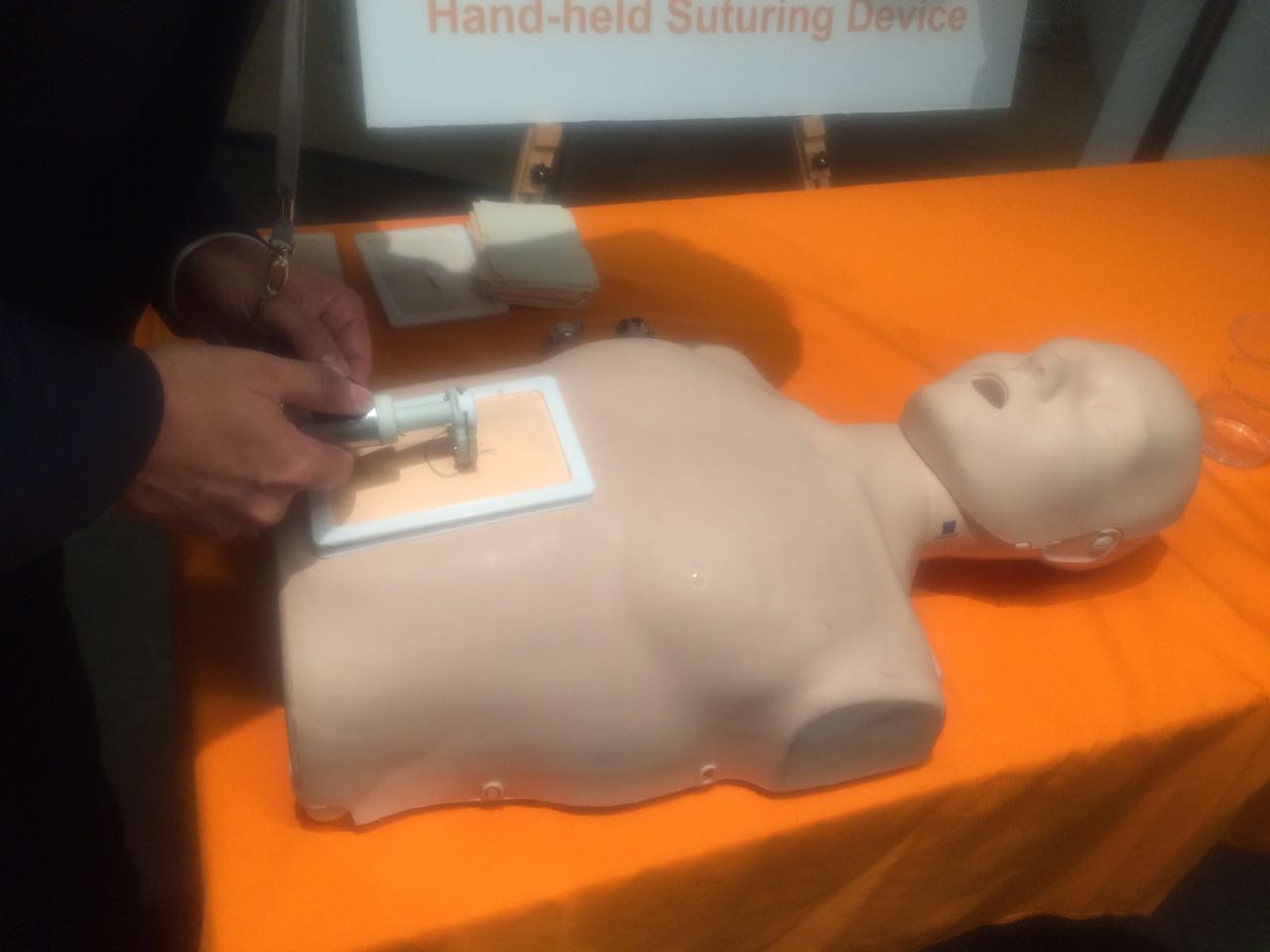

The automated handheld suturing device

The Sutrue team worked with cardiologist Dr. Richard Trimlett to help translate the manual stitching specifications into the handheld device. The miniature gears allow a rotating needle to tilt and adjust to suit the angle of a surgeon during cardiac, thoracic, cranial and gastrointestinal operations.

I had the opportunity to use the device, it was comfortable to hold and fairly lightweight. I pressed one of the two buttons which activated the needle immediately. However, an inexperienced user (such as myself) found it hard to complete a full stitch.

For medical professionals, the handheld automated suturing device creates a smoother and faster stitch when compared to traditional methods. The device is able to stitch minimally invasive keyhole incisions. This reduces the need for longer and deeper high-risk cuts that are more difficult to close when stitching.

The robotic automated device

During the Q and A portion of the press event, the Sutrue team discussed that the robotic automated device came after the handheld device. Once the handheld device was completed, the engineers were able to apply the angles from a surgeon’s perspective to the Zeus medical robot.

To test the robotic device at the press event, Berry was required to wear a pair of 3D glasses. This enabled him to view the separate computer monitor where the suturing activity was taking place.

Berry demonstrated the speed of the device by producing a single stitch in under a second, as opposed to an experienced surgeon, who can take up to 25 seconds.

Dr Trimlett believes that this device can be influential for the future of robotic surgery due to its ability to perform more low-risk keyhole surgeries at a faster rate.

The Queen Elizabeth Hospital in Birmingham, UK have also recently implemented 3D Printing technology to improve surgical time with the Stratasys Objet Eden350V 3D Printer.

Future commercialization for devices

Sutrue plans on commercializing their automated devices within hospitals and veterinary and dental practices. Sutrue has also been approached by bespoke clothing manufacturers with the potential to use their automated suturing devices for fabric stitching.

For more of the latest 3D printing product developments subscribe to the 3D Printing Industry newsletter, follow us on Twitter and like us on Facebook.

Looking for a change of pace? Sign up for 3D Printing Jobs here.

Featured image shows Additively manufactured parts of the automated suturing device on the build plate of an Mlab cusing from Concept Laser. Photo via Concept Laser