Virginia Tech and Lawrence Livermore National Laboratory (LLNL) have developed a high resolution method of 3D printing graphene that is “an order of magnitude greater” than any 3D printed before.

Aiming to unlock ways to make graphene in any shape or quantity, the researchers have moved one step closer to harnessing its true potential as the strongest material ever tested.

The strongest material ever tested

By nature, graphene is a 2D material consisting of a single layer of atoms. It is the basic structural element of forms of carbon such as graphite, diamond, charcoal. Though graphene has a strength excelling any tested material, and a high rate of conductivity, these properties cannot be fully exploited in its natural 2D state. So scientists have accepted the challenge of giving the material a new dimension.

UK government Technology Strategy Board Innovate UK launched a graphene specialist interest group in 2017. In the same year, Kansas State University made it into the Guinness World Book of Records for its 3D printed graphene aerogel. Another approach, employing a laser, 3D prints a graphene foam.

Such light, low density structures are especially suited 3D graphene, as the airy composition allows it to retain its lightness, while exhibiting amazing strength.

3D printing graphene in “any structure you want”

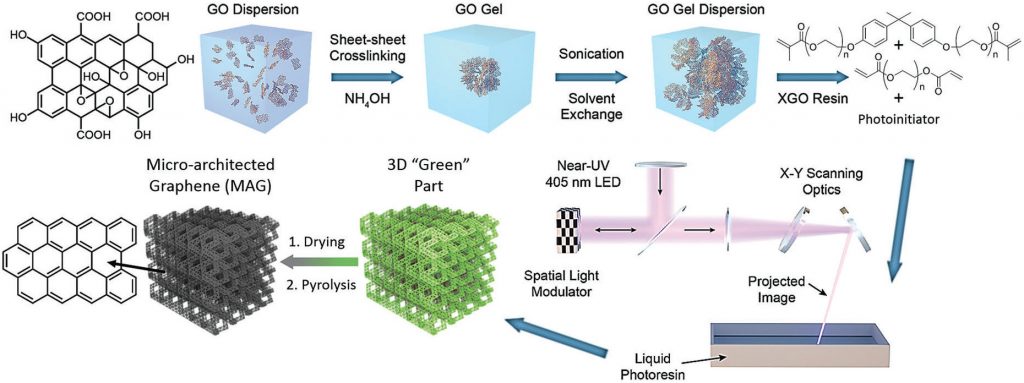

Virginia Tech and LLNL’s method of 3D printing graphene relies on dispersing the material within a gel to make a resin.

Projection Micro Stereolithography (PuSL), a relative of two-photon lithography, is selected for 3D printing in this instance as it is capable of reaching a resolution of 10μm – as close to the atomic resolution of 2D graphene as possible.

PuSL, via near-UV LED light, then is used to cure the graphene resin into a solid. At this point, the product is “green” 3D printed structure. To finish the part off, it has to be dried in a furnace to rid it of surplus content initially added to make it a gel.

Ryan Hensleigh, Virginia Tech Ph.D. student and lead author of the paper discussing the 3D printed aerogel, says the technique is “a significant breakthrough compared to what’s been done,”

“We can access pretty much any desired structure you want.”

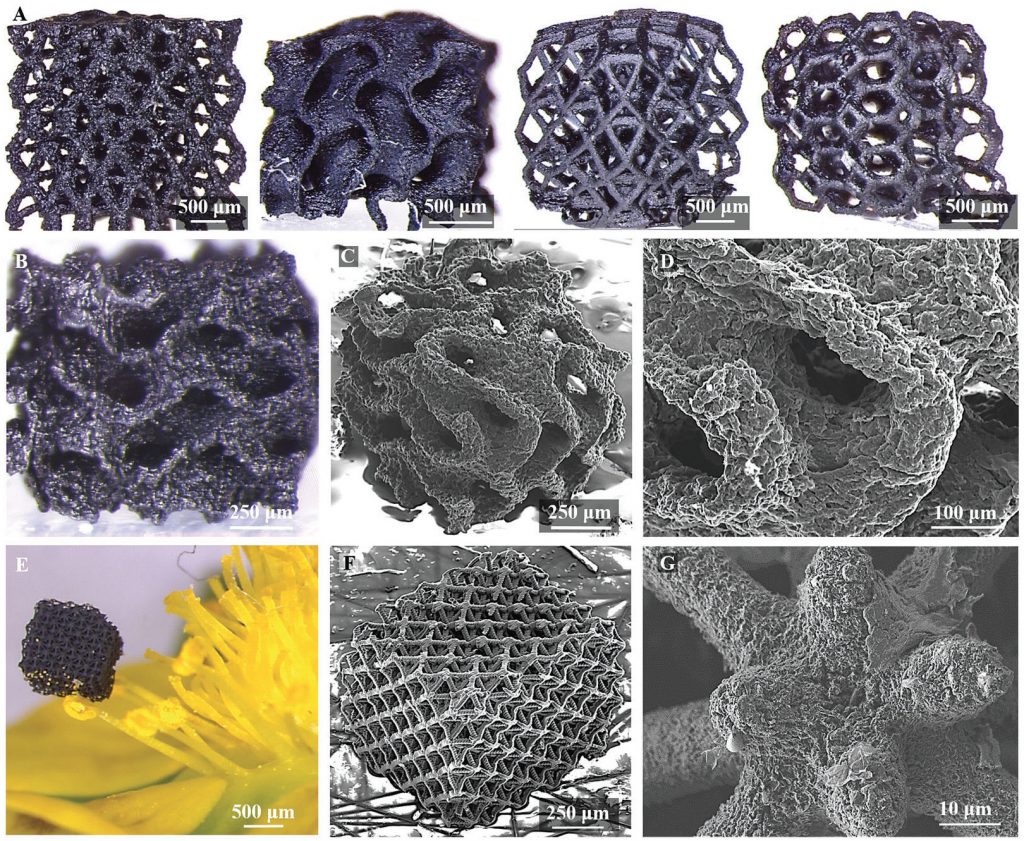

Test structures of 3D graphene highlighted in the study take on the complex shapes of gyroids and lattices.

Graphene energy storage

After 3D printing, the so-termed micro architected graphene (MAG) was tested for its mechanical properties and electrical conductivity. According to Virginia Tech assitant professor Xiaoyu “Rayne” Zheng, the results showed how to “make a complex, three-dimensional architecture of graphene while still preserving some of its intrinsic prime properties.”

“Usually,” Zheng points out, “when you try to 3D print graphene or scale up, you lose most of their lucrative mechanical properties found in its single sheet form.”

In future work, the team plans to explore the potential of its micro architected graphene for energy storage uses.

“Additive manufacturing of complex micro-architected graphene aerogels” is published open-access in Materials Horizons journal. It is co-authored by Ryan M. Hensleigh, Huachen Cui, James S. Oakdale, Jianchao C. Ye, Patrick G. Campbell, Eric B. Duoss, Christopher M. Spadaccini, Xiaoyu Zheng and Marcus A. Worsley.

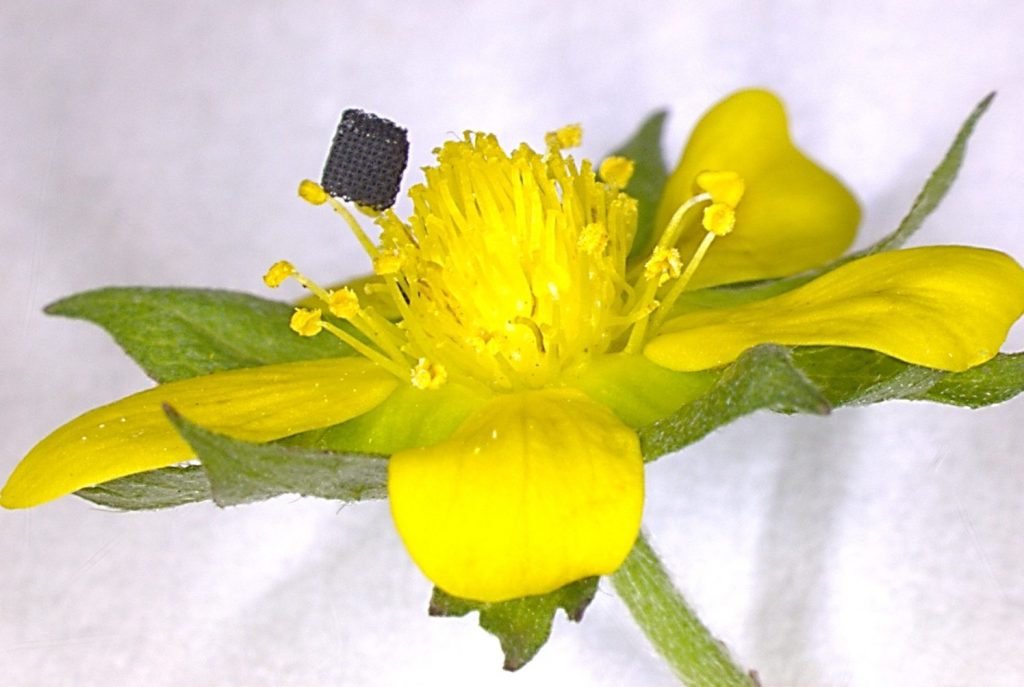

Featured image shows a 3D printed graphene aerogel. Photo via Virginia Tech