The maker universe has never given itself a limit, it encompasses every creative possibility, digital or otherwise, additive or subtractive, the freedom to do, and sometimes to complicate, is on the agenda, which is the precondition for fun, for experimenting, for presenting a result to personal satisfaction. OpenBuilds is one the clearest representations that is making this possible. (I’m anxiously awaiting the Maker Faires in New York and Rome, can you tell?)

We all know that 3D printing has been playing a primary role in shaping the Maker movement in recent years and I believe this is because it has been the tool that has really sparked the imagination of the entire DIY community — Land also had an interesting take on this theme in his article yesterday. 3D printing allows for the creation of objects just as they are imagined and dreamed by common people and in recent years it has been taking hold with the same intensity as within the professional industry.

The two worlds are sharing something: the maker one participates with ideas and vitality, the industry one instead gradually reveals its master secret: automation for continuous and homogenous production. The tools for automation are the heart of industrial production, and inside them, linear movement is one of the main characteristics. The application of a precise control when changing the position of a cartesian axis (x, y, z) is obviously the fundamental element for this sector, as in that of industrial Robots in general and their mechanical parts.

The solutions offered by the market are many, although the costs are extremely high because companies that are growing constantly need to meet higher demand and thus are pushing technological boundaries to obtain more efficiency, speed and quantity. The larger companies are, the more they have dedicated systems — the giants of this industry specialize themselves in providing them. It happens because those who seek quality, in the end have fewer surprises, as always.

The experience of self-produced desktop 3D printers and linear robots, on the other hand, always had to confront itself with the issue of finding elements as guides, trucks, bearings, acme screws and so forth. The shops for robotics or modelling, at least in Europe, almost never cater for these products in their catalogues. And only in very recent times has there been a significant improvement in this field.

Makers have often thought of doing it for themselves: in the Open Hardware spirit and license, several projects were born that have implemented innovative solutions, particularly for what concerns the costs issue. Solutions such as Makerslide are the basis for many important FFF 3D printers on the market, especially the more experimental ones, such as DeltaMaker (a great success on Kickstarter), proving Makerslide was exactly what many were looking for.

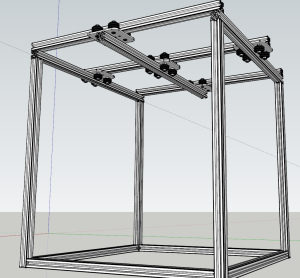

OpenBuilds continues with this mission; I have been following them since they started and was immediately struck by the variety of combinations that were offered from the start — CNC, Plotters, 3D Printers — with varying structures thanks to interchangeable components. Any experimentation is allowed, although success is never guaranteed, not even for industrial applications, where producers close the compatibility of their systems so as not to suffer competition from low quality copies.

OpenBuilds essentially offers a movement system based on aluminium profiles, which proves to be a good choice for the soundness of any system. The brilliant idea was not so much thinking about the slide with V-Wheels, but to reverse the classic coupling. In this case the V faces toward the inside, along the sides of the profile. This solution brings many benefits: from saving space and cost, easy calibration, stability, professional tolerances with all the comfort and workability of extruded aluminium. The resin shell of the bearings, moreover, dampens the sound impact of the classic ball bearings on steel shafts. In short, even though the underlying technology is not new, the improvements on the overall set are remarkable.

Openbuilds is committed to be accepted: directly donates a portion of its profits to the Open Hardware community, through the Fair Share Program, and has created an active and highly respected forum and community. I’m certain we will continue to see them as protagonists behind the scenes of many upcoming projects of the border between Making, Professional, and Industrial and in the field of additive as well of subtractive manufacturing.Because now more and more people are starting to think big (such as BigRep), and dreaming one day of meeting the great Materialise Mammoth.