Materialise’s recent IPO brought in around $125 million for the Belgian company to invest in its future. During my trip through some of the top 3D printing companies in Northern Europe I just had to stop by and see for myself what that could mean. So, after visiting the future of consumer 3D printing and bioprinting in Holland and the present of industrial metal 3D printing in Germany, I went to see how this all comes together at one of the top 3D printing service and software providers in the world.

Based in Leuven, which is also home to the Stella Artois brewery and tons of delicious local Belgian beers, Materialise is not your average 3D printing company. Unlike many other emerging or industrial realities, most people around Leuven have heard about it and know what it does. That’s because, while the world has just recently been marvelling at the new possibilities offered to design by 3D printing technologies, Materialise has been exploring these possibilities for years and has already partnered on tens of high level experimental projects with top designers, stylists and artists — many of them local.

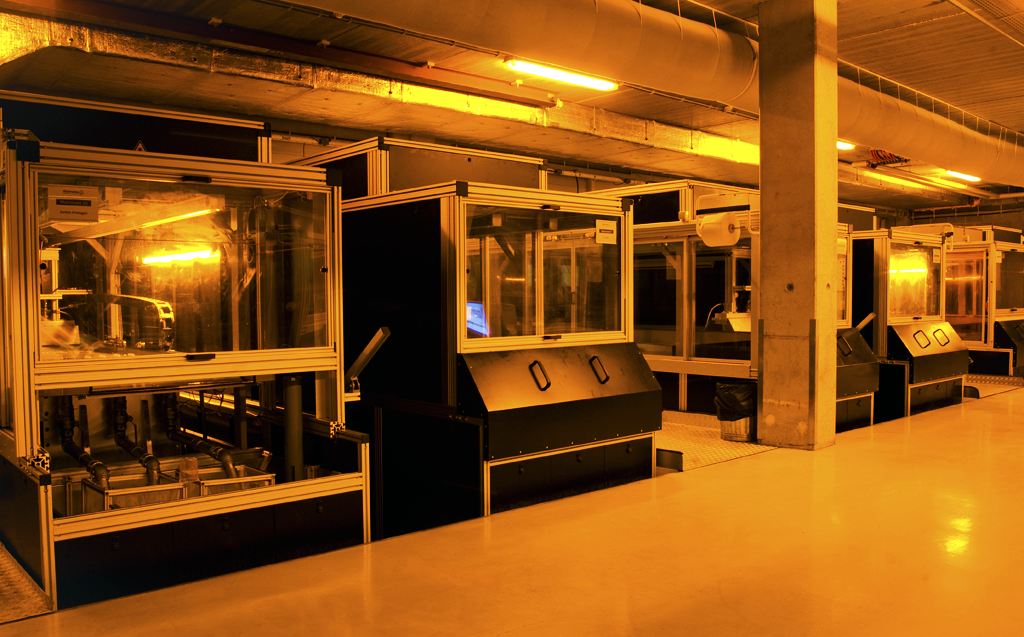

I meet with Vanessa Palsenbarg, Corporate Communications Specialist, and Lies Peeters, Marketing Coordinator, who very kindly offered to take me on a tour of the building, which hosts close to 100 industrial 3D printers. These include the gigantic (proprietary) Mammoth 3D printers, “the stuff of legends”, that everyone has heard about but can hardly believe. They live up to their name and are truly capable of 3D printing objects as long as 2.10 meters, in resin, using the SLA process.

During my travels, I have noticed that for all 3D printing companies showing their premises to a journalist it is a very delicate matter – as no one wants to sacrifice any competitive edge just to show off – but for Materialise it is even more delicate as the company has just gone public on the NASDAQ US index and, while that means it has to disclose some information, it also means there are some things it just cannot reveal. Being that I am also an investor, the matter is even more complex.

Nevertheless I did get to see Materialise’s SLS room, with more EOS and 3D Systems machines than I could count, as well as their SLA (mostly 3D Systems’) and FDM (with a full array of Stratasys’ Fortus 900mc) rooms. I even got to see the Mammoth and it is just as incredible as it sounds. There are two arrays of machines and each one is as tall as a two story building. Seeing the size of a piece 3D printed to the full capability of a Mammoth is much more impressive in person than in pictures. Materialise also offers Stratasys’ Objet Polyjet technology, ZCorps/3DSystems full colour 3D printing as well as vacuum casting and reaction injection moulding (RIM).

Metal 3D printing at Materialise is currently done through lost wax castings (for the iMaterialise consumer 3D printing service) or through external partners but my own personal impression (and I stress that it is only my opinion and not in any way suggested by anything I saw or heard during my visit) is that its policy on that is going to change soon. Perhaps that’s just what part of that €125 million will be used for.

This was the last stop on my Northern European 3D Printing Tour. I apologize to Jonas Martens of the Perpetual Plastic Project, whom I was not able to meet with (but I will be back soon), and I go back home with the feeling that the Fab Labs, 3D Hubs, Printed in Space, Leapfrog, Ultimaker, colorFabb, Concept Laser and Materialise are all connected, not just by 3D printing but by the common vision of a better future with endless possibilities. A vision I most definitely want to share.