3D printed QR codes are the latest development in the prevention of counterfeiting and intellectual property (IP) theft. Created by an international team of researchers from NYU Tandon, New York, and NYU Abu Dhabi, United Arab Emirates (UAE), these invisible tags can be internally embedded within additive manufactured components, to be read later only by trusted parties.

“You need to be cost efficient and match the solution to the threat level,” explains Nikhil Gupta, NYU Tandon associate professor of mechanical engineering, “Our innovation is particularly useful for sophisticated, high-risk sectors such as biomedical and aerospace, in which the quality of even the smallest part is critical.”

3D printed QR “clouds”

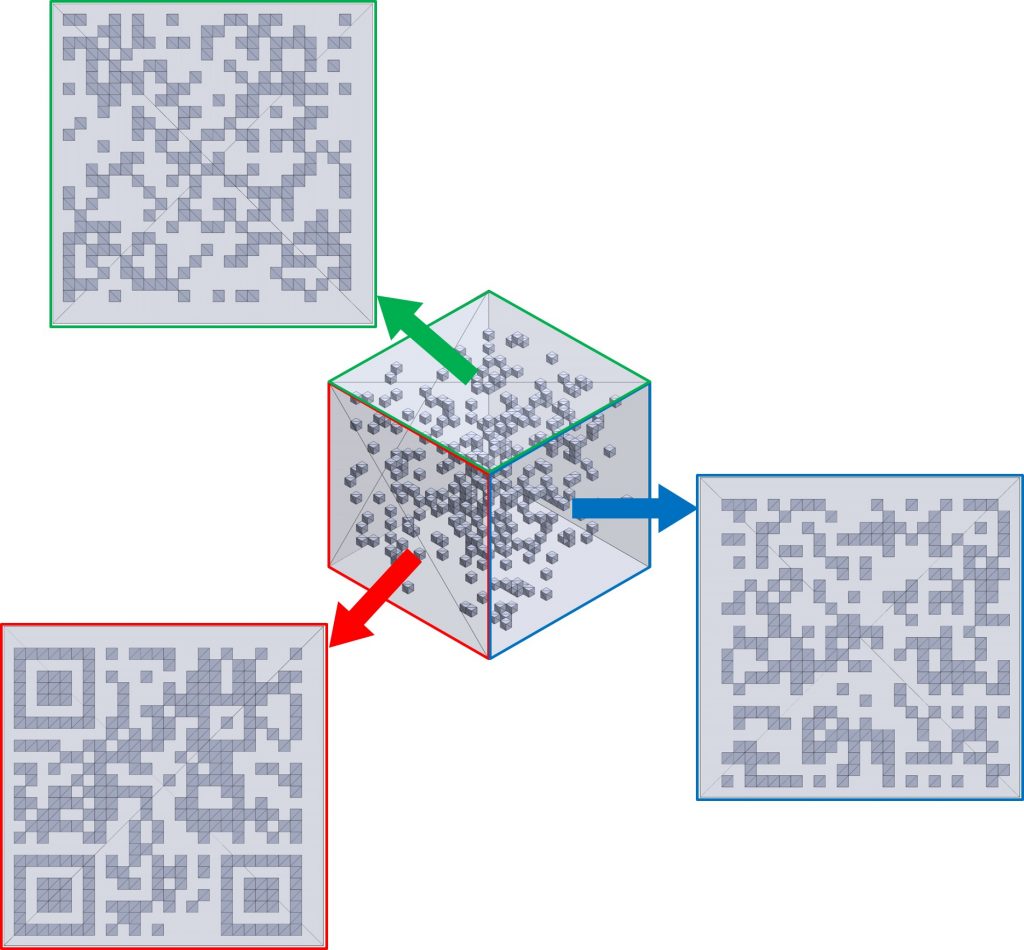

The tags developed by the team at NYU explode a typical 2D QR code into a 3D cloud of pixels.

When aligned properly the pixels can be scanned, however, working with this extra dimension, the team are able to encode the cloud with multiple faces – obscuring the one “true” code.

“By converting a relatively simple two-dimensional tag into a complex 3D feature comprising hundreds of tiny elements dispersed within the printed component, we are able to create many ‘false faces,'” explains Gupta, “which lets us hide the correct QR code from anyone who doesn’t know where to look.”

To read the code, which can be programmed to contained part information such as serial number and place produced, users require a micro-CT scanner or similar device as used for non destructive testing (NDT). Then the part must be oriented at just the right point to show the authentic face.

Encoded polymers and metals

NYU’s QR encoding method has been trialed on thermoplastics, photopolymers and metal alloys. Under stress tests, QR encryption proved to have negligible effect on the structural integrity of each part.

As Fei Chen, lead author of the study, points out, “To create typical QR code contrasts that are readable to a scanner you have to embed the equivalent of empty spaces. But by dispersing these tiny flaws over many layers we were able to keep the part’s strength well within acceptable limits.”

Secure 3D printing

Assuring the security of 3D printed models is of upmost importance to a variety of high value industries.

In 2017, The Atlantic Council shared its concerns about the cybersecurity risks of additive manufacturing, and the U.S Department of the Navy revealed plans to use a blockchain to control its 3D printers.

Gupta, Chen et al’s research was funded in part by the U.S. Office of Naval Research.

The full paper discussing the group’s most recent research is published as “Embedding Tracking Codes in Additive Manufactured Parts for Product Authentication” in Advanced Engineering Materials journal. It is co-authored by Fei Chen, Yuxi Luo, Nektarios Georgios Tsoutsos, Michail Maniatakos, Khaled Shahin and Nikhil Gupta.

For cutting edge research, aerospace and more additive news subscribe to the 3D Printing Industry newsletter, follow us on Twitter, and like us on Facebook.

On the lookout for new talent or seeking a career change? Search and post 3D Printing Jobs now.

Featured image shows a graphic demonstration of a perfectly aligned, 3D printed QR cloud. Image via Nikhil Gupta