Northrop Grumman, an American global defense company, has awarded $150,000 to the U.S. Naval Academy (USNA) Foundation in support of additive manufacturing programs in the Academy’s Division of Engineering & Weapons.

The grant will support the development of the USNA MakerSpace, a student-faculty 3D printing laboratory. The funding will be further utilized in assisting USNA student capstone projects aligned with Northrop Grumman’s own additive manufacturing programs and interests.

“Additive manufacturing has been a growing interest area for the Navy and the Naval Academy for the last several years and support from Northrop Grumman will enable advanced student research across a wide array of interdisciplinary projects,” explains CAPT Brad Baker ’94, USN, associate professor of mechanical engineering at the Academy.

“The Naval Academy’s research in additive manufacturing to support the warfighter aligns well with Northrop Grumman interests, and together we hope to better support overall Navy additive manufacturing goals by training the next generation of Navy and Marine Corps officers.”

3D printing at Northrop Grumman

Northrop Grumman provides security products and solutions in autonomous systems, cyber, C4ISR, space, strike, and logistics and modernization to customers worldwide.

In the 3D printing industry, the firm has played a part in the development of DARPA’s Tactically Exploited Reconnaissance Node (TERN) drone, which has been tipped to contain 3D printed parts.

Many of the firm’s 3D printing activities have been within the space industry. Northrop Grumman was announced as a subcontractor on Californian off-world manufacturer Made In Space’s Archinaut 3D printing project. Initially awarded a contract in 2016, the Archinaut is a machine developed by Made In Space for the construction of large structures, including satellites, in low gravity conditions.

Furthermore, Northrop Grumman’s Cygnus spacecraft helped to deliver the Refabricator system, developed by the US-based aerospace company Tethers Unlimited Inc. (TUI), to the International Space Station (ISS). It has also helped to test autonomous robotic systems developed by The Technology House (TTH) using Carbon’s DLS 3D printing technology.

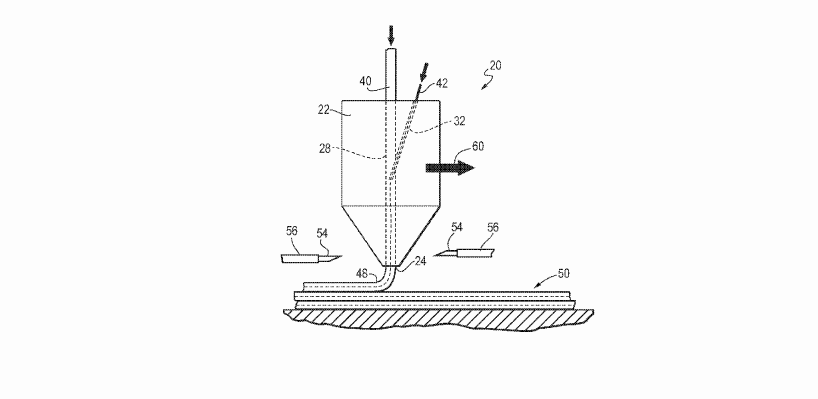

Northrop Grumman also holds its own IP within the additive manufacturing field. In 2019, the company was successfully granted patents for a composite 3D printing method and material.

Supporting 3D printing projects at the U.S. Naval Academy

USNA’s MakerSpace is organized and maintained by the Academy’s Center for Material Characterization. The 3D printing laboratory is designed to provide a “modern, open, and adaptable” space for midshipmen to create materials projects intended to better equip soldiers in combat. As well as further supporting the facility, the funding will also be put forward towards the MakerSpace’s associated engineering programs.

“Advancements in additive manufacturing are enabling the development of next-generation materials and equipment with reduced life-cycle costs to give our warfighters the tactical advantage against emerging threats in complex combat environments,” comments Larry Ferranto, vice president, manufacturing, Northrop Grumman.

The student capstone projects recieving assistance from the grant includes a satellite component for the ISS, components for the Formula Society of Automotive Engineers racecar competition, and a redesign of the U.S. Marine Corps All-Purpose Lightweight Individual Carrying Equipment Pack. These all fall in line with Northrop Grumman’s additive manufacturing programs, which are carried out through its Northrop Grumman Mission System arm dedicated to creating military radar, sensors and related products.

Ferranto concludes, stating “The Naval Academy’s research in additive manufacturing to support the warfighter aligns well with Northrop Grumman interests, and together we hope to better support overall Navy additive manufacturing goals by training the next generation of Navy and Marine Corps officers.”

Subscribe to the 3D Printing Industry newsletter for the latest news in additive manufacturing. You can also stay connected by following us on Twitter and liking us on Facebook.

Looking for a career in additive manufacturing? Visit 3D Printing Jobs for a selection of roles in the industry.

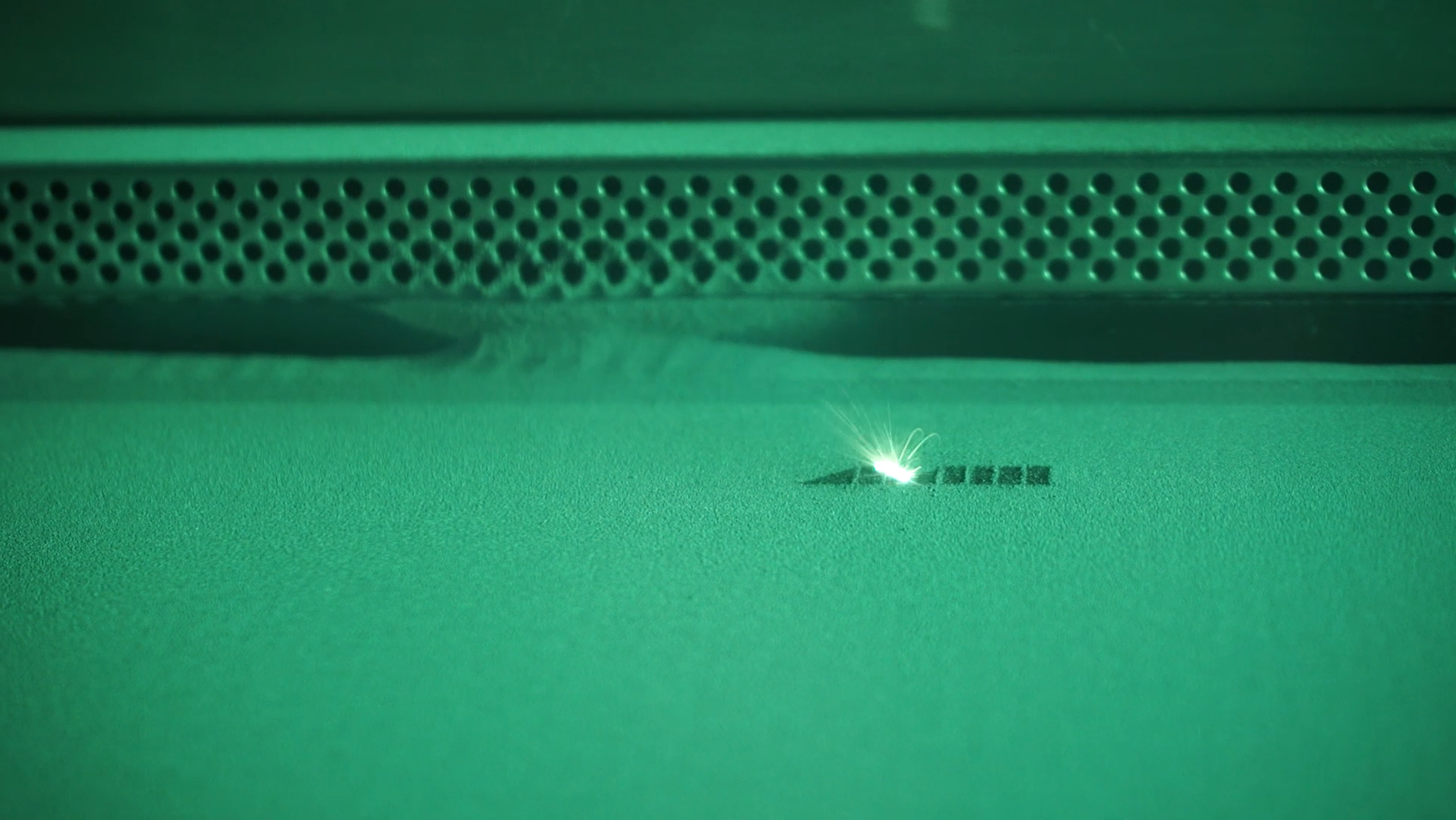

Featured image shows Northrop Grumman Partners with US Naval Academy Foundation to Support Additive Manufacturing Education. Photo via Northrop Grumman.