American global defense company Northrop Grumman has been granted a patent for a composite 3D printing process and device.

First filed December 8, 2015, the patent was granted January 8, 2019. It focuses on a fused filament fabrication (FFF) method, for depositing long-fiber reinforced materials.

3D printing at Northrop Grumman

In the 3D printing industry, Northrop Grumman is perhaps best known for its role in the development of DARPA’s Tactically Exploited Reconnaissance Node (TERN) drone. Built to carry 600 lbs of artillery for the purpose of combat strikes, the TERN has been a work-in-progress for the company since 2015. Full details of its construction of course remain undisclosed, however the prototype vehicle is tipped to contain 3D printed parts.

Other components of Northrop Grumman aerospace systems are also likely 3D printed through supply contractors such as the Moog Aircraft Group, and its own private manufacturing departments.

Alongside NASA and Oxford Performance Materials the company co-developed the OPM B-Basis database, and its Selective Laser Sintering (SLS) additive manufactured Nylon 12 Database is available through America Makes.

As an industry built on the shoulders lightweight, high strength aerospace and automotive requirements, composite materials are a popular pursuit in 3D printing.

In 2018, leading 3D printer OEM Stratasys released its Fortus 380mc Carbon Fiber Edition to tap into the needs of this market. Fortify, a 3D printing startup based in Boston, also won the Formnext 2018 startup challenge for its Digital Composite Manufacturing technology. And, in large format 3D printing, there is Thermwood Corporation‘s LSAM system which works with composite materials.

Northrop Grumman’s composite 3D printer

Northrop Grumman’s patented composite 3D printing method was invented by Jerrell Nardiello, Robert J. Christ, John A Crawford and John S. Madsen.

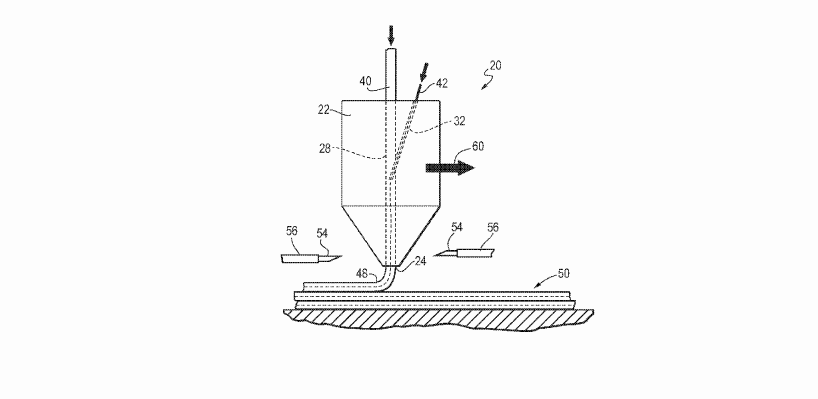

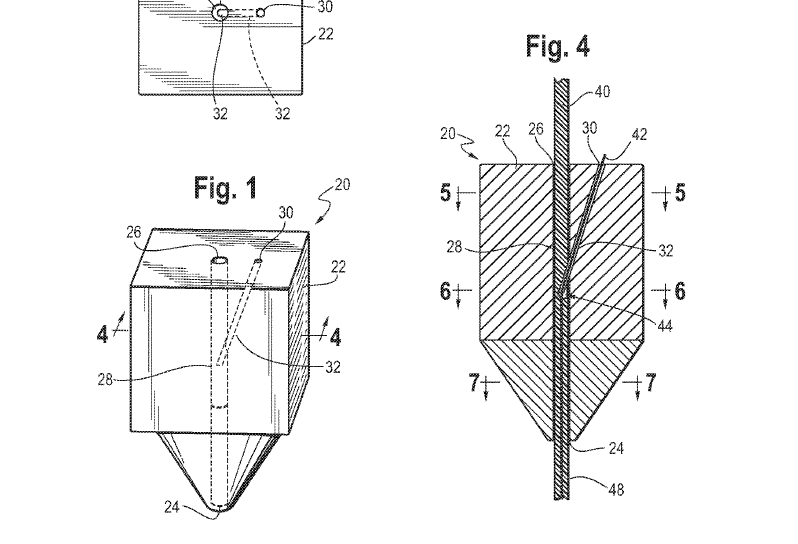

In the document, the inventors detail the construction and abilities of an extrusion nozzle and cutting system. The cutting system, a necessity for composite systems, is used to prevent stringing of fibers when the head moves to another part of the object in-printing.

As stipulated in the patent copy, potential feedstocks for the system include PLA, ABS, PEI, nylon, polystyrene, PEEK, PEKK and PES, with “fiberglass, carbon, aramid, polyester and cotton or other plant-based” fiber reinforcements. As demonstrated in Fig. 1 and Fig. 4 below, the nozzle encapsulates two inlets – one for the thermoplastic (26), and second for inserting long fibers.

At present it is unclear whether Northrop Grumman intends to manufacture this composite additive manufacturing system for commercial purposes.

U.S. patent No. 10173410 B2, or “Device and method for 3D printing with long-fiber reinforcement” granted to Northrop Grumman Systems Corporation, Virginia can be viewed in full online here.

Select your nominees for the 2019 3D Printing Industry Awards now. For more of the latest additive manufacturing research & development news, subscribe to our 3D printing newsletter. You can also join us on Facebook and Twitter.

Looking for a job in R&D? Visit our 3D Printing Jobs board.

Featured image shows patent drawing, figure 1, of a composite material depositing nozzle. Image via US10173410, awarded to Northrop Grumman.