Aurora Labs, an Australian metal 3D printer manufacturer, has announced that tests of its metal additive manufacturing process Rapid Manufacturing Technology (RMT) have achieved print speeds of 113 kg per day.

RMT is integrated into the company’s large-format Alpha 3D printer (also known as the RMP), and with this speed is said to deliver parts at 55 times the market speed, which has been identified as 1.96 kg of Titanium per day. David Budge, Managing Director of Aurora Labs explained:

“This step in the development of the technology is the latest in a long line of impressive developments since the company’s inception in 2014. Printing on multiple levels simultaneously at high speeds is what we believe will ultimately allow us to print up to 1000 kg in one day.”

Multi Concurrent Printing

Similar to Direct Metal Laser Sintering (DMLS), Aurora Labs’ Multi Concurrent Printing (MCP) within RMT melts and fuses layers of powder to form 3D models. Nevertheless, MCP lays down multiple layers of powder at the same time; during this process, an area behind each powder gate allows for multiple spaces for 3D printing.

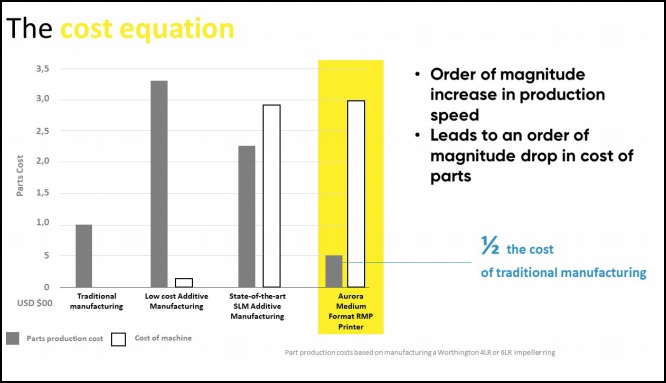

This is designed to significantly accelerate conventional metal additive manufacturing. Budge added, “The primary factory delivering an end product cost competitive with traditional is the speed of the machine. This is why Aurora is looking outside traditional 3D printing markets to sectors like mining, oil & gas, marine and automotive.”

Several months ago, the company successfully 3D printed the first component with a complex lattice structure using RMT. This was done at a print speed evaluated to be eight times greater than Aurora Labs’ defined standard market speed of a 3D printer with a similar size, which is 1.96 kg per day.

Accerlating metal additive manufacturing

This week, Aurora Labs closed a $5 million(AU/US$3.5 million) share placement round, which will be used to further develop RMT as well as act as working capital. Prior to this, in an interview with 3D Printing Industry, Nathan Henry, Director of Marketing and Business Development at Aurora Labs said:

“RMT is being developed with a focus on addressing the need to make things at a speed that makes it economic. This brings down the amortization costs and opens up a much wider market within additive manufacturing and makes it viable to compete with things like casting and subtractively manufactured parts with CNC.”

Remember, nominations for the 3D Printing Industry Awards 2019 are open. Tell us the enterprises, technology, and individuals leading the additive manufacturing sector.

Want the latest 3D printing news? Subscribe to the 3D Printing Industry newsletter, follow us on Twitter and like us on Facebook.

Looking for a fresh start this year? Visit 3D Printing Jobs to commence your career in additive manufacturing.

Featured image shows MCP within RMT in the Alpha 3D printer. Clip via Aurora Labs.