Stratasys has commenced shipping of its latest FDM 3D printer designed to address the growing demand of carbon-fiber composite applications.

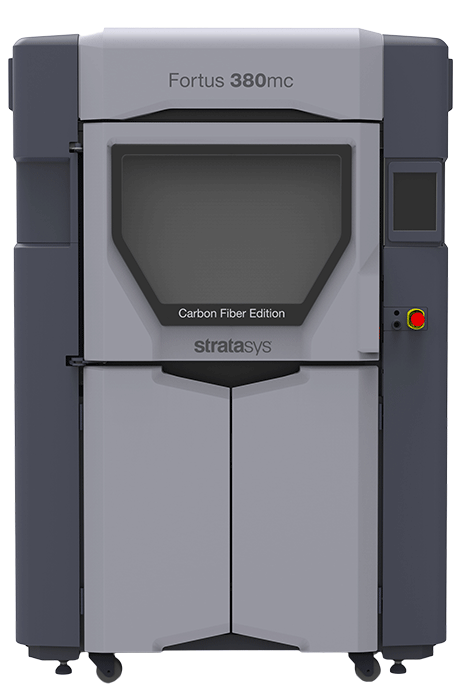

The Fortus 380mc Carbon Fiber Edition (CFE) industrial 3D printer, priced at $70,000, is the cost-effective option from Stratasys’ high-end production 3D printer range which is priced from $200,000.

“Our customers are pushing us for easier access to carbon fiber,” explained Pat Carey, Senior Vice President of Sales at Stratasys.

“They want an affordable solution but in a reliable, industrial-quality system. So we’re now offering a more accessible system that’s based on our Fortus 380mc platform. Because the 380mc CFE is dedicated only to carbon-fiber-filled Nylon 12 and one other material, we’re able to currently offer it at the lowest price for any of our industrial printers.”

Nylon 12CF

According to Stratasys, composite material has seen a year-over-year market growth of 8 to 12% due to its lightweighting capabilities, which decreases energy consumption. Last year, reducing the need for high-strength metal parts, Stratasys released its advanced carbon fiber composite material, Nylon 12CF.

Designed for functional prototypes and end-use components in automotive and aerospace industries, Nylon 12CF displays high fatigue resistance and stiffness. Furthermore, this material is 35% chopped carbon fiber by weight and one of two materials compatible with the new Fortus 380mc CFE 3D printer (with the other material being ASA).

The Nylon 12CF applications also include short production runs in a high-strength material and producing lightweight assembly tools.

Team Penske and Stratasys

In 2017, Team Penkse, an American professional sports car racing team and Stratasys announced a strategic partnership which has resulted in innovative, redesigned race car parts – such as a 3D printed fuel line hose handle – with improved performance.

Recently, Team Penske used the Nylon 12CF to produce lightweight mirror housing for its NASCAR race teams. The carbon-fiber-based housing demonstrated high impact resistance and high stiffness, each of which is critical in motorsports. The team also used this material to avoid flexing of the thin-walled parts of the housing under the aerodynamic loads produced on track.

“It’s estimated that each 10% reduction in vehicle mass drives a 6 to 8% increase in fuel economy,” stated Stratasys.

Technical specifications of the Fortus 380mc Carbon Fiber Edition 3D printer

The Fortus 380mc CFE is said to produce parts with repeatable dimensional accuracy, no appreciable warpage or shrinkage, and high tight tolerances.

| System Size | 129.5 cm x 90.2 cm x 198.4 cm (51 x 35.5 x 78.1 in) |

| Build Volume | 355 x 305 x 305 mm (14 x 12 x 12 in) |

| Weight | 1,325 lbs (601 kg) |

| Materials | Nylon 12CF, ASA |

| Layer Thickness | Nylon 12CF: 0.254 mm (0.010 in.)

ASA: 0.127 mm (0.005 in.) – 0.330 mm (0.013 in.) |

| Accuracy | Parts are produced within an accuracy of .0015 mm (0.005 in) |

| Power Requirements | 208VAC 3 phase, 50/60 Hz, 18 Amps |

| Operating System | Microsoft Windows 10 (Pro, Enterprise, Education), Microsoft Windows 8.1 and Windows 8 (Pro, Enterprise), Microsoft Windows 7 (Pro, Enterprise, Ultimate), Microsoft Windows Server 2012 R2. |

“For many years, the additive manufacturing industry has seen a need for a diversity of machines that produce parts in high-strength composite materials,” said Terry Wohlers, President of Wohlers Associates, an additive manufacturing industry consultancy based in Colorado.

“I’m hopeful the newest machine from Stratasys will help to meet this need by offering strong parts in carbon fiber and Nylon 12.”

For more of the latest 3D printing news sign up to the 3D Printing Industry newsletter, Also, follow us on Twitter, and like us on Facebook.

On the lookout for new talent or seeking a career change? Search and post 3D Printing Jobs for opportunities and new talent across engineering, marketing, sales and more.

Featured image shows the Fortus 380mc Carbon Fiber Edition 3D printer. Photo via Stratasys.