Leading 3D printer manufacturer Stratasys has announced further tooling collaborations with American sports car racing team Team Penske at the 2018 International Manufacturing Technology Show (IMTS) in Chicago.

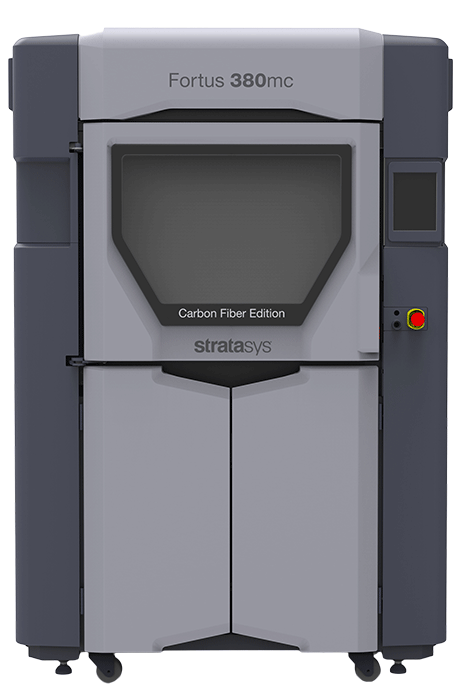

Currently using two of Stratasys’ industrial 3D printers, the Fortus 380mc Carbon Fiber Edition (CFE) industrial 3D printer and the F900, Team Penske is gaining a competitive edge for car testing, prototypes, and production parts.

“While drivers are focused on outperforming one another during racing season, the real competition starts weeks before with design and development in the shop,” said Matt Gimbel, Team Penske Production Manager.

“The power to deploy 3D printing early in the process gives Team Penske a tremendous advantage in the production of better, stronger and more aerodynamic race car parts. The faster parts get on the race track, the better our team competes: Stratasys technology enables us to do just that.”

The Fortus 380mc Carbon Fiber Edition & F900 3D printers

The Fortus 380mc CFE, which began shipping last month, is the latest FDM 3D printer from Stratasys designed to address the growing demand of carbon-fiber composite applications. This system primarily uses Nylon 12, a high-strength, high fatigue resistant carbon composite with lightweighting capabilities.

Prior to this, Stratasys unveiled the F900 Production 3D printer, the third generation of Stratasys’ flagship series of FDM 3D printers, at this year’s RAPID + TCT event. This system is built to produce parts with the high repeatability and performance using ULTEM 9085 resin.

“We’re delivering true industrial manufacturing solutions with unmatched levels of repeatability, reliability, and performance required for tooling and final part production. And this is being validated across industries with market leaders like Penske, Lockheed Martin, Audi, and GKN Aerospace,” explained Rich Garrity, President Americas at Stratasys.

Team Penske and Stratasys’ partnership

In 2017, Team Penkse and Stratasys announced a strategic partnership which has resulted in innovative, redesigned race car parts – such as a 3D printed fuel line hose handle. With the ongoing implementation of additive manufacturing, the team has created a lightweight carbon-fiber-based housing mirror housing for its NASCAR race teams, jigs and fixtures, engineering prototypes, and additional end-use race car components.

Thanks to 3D printing technologies, Team Penske has also improved the overall aerodynamics of its race cars. The optimized vehicles are set to take part in the NASCAR, INDYCAR and IMSA circuits.

For more releases and news live from IMTS 2018 and the wider 3D printing industry, subscribe to our newsletter, follow us on Twitter, and like us on Facebook.

Searching for new talent or seeking a career change? Search and post 3D Printing Jobs for opportunities and new talent across engineering, marketing, sales and more.

Featured image shows the No. 2 Team Penske NASCAR Cup Car with integrated 3D printed parts. Photo via Team Penske.