Researchers from Northeastern University have devised a 3D printable living material capable of growing and healing itself.

The proof-of-concept study sought to harness the properties that are unique to the materials that make up living things for a wide range of purposes, ranging from therapeutic and medical, to industrial and even space applications.

Formed from genetically engineered E. coli, the scientists’ material is “truly living” as it is entirely biological and is not blended with anything else.

“Like a tree has cells embedded within it and it goes from a seed to a tree by assimilating resources from its surroundings in order to enact these structure-building programs, what we want to do is a similar thing but where we provide those programs in the form of DNA that we write and genetic engineering,” said Neel Joshi, Associate Professor of Chemistry and Chemical Biology at Northeastern.

Printing living cells

Genetically modified E. coli has been used in the creation of “living” 3D printable materials before, by researchers from the MIT Media Lab, Harvard University’s Wyss Institute, and the Dana-Farber Cancer Institute. The team’s Hybrid Living Material (HLM) fabrication platform used a combination of inkjet 3D printing, resins, and chemical signals to activate responses in biologically engineered microbes, with particular applications in the medical sector.

Elsewhere, scientists around the world have been experimenting with 3D printing living cells for bone-mimicking structures, to produce sensory neurons, and to study their mechanoresponsive behavior. However, while these materials contain living cells, they are not considered to be “alive”, as they are combined with various inert substances.

The Northeastern team’s new microbial material is, in contrast, entirely biological and is what they consider to be “truly living”.

Programming E. coli for 3D printing

E. coli produces a particular protein that acts as a natural building block, called Curli fibers, which attach to a surface and one another to form a community. The same properties that make the Curli fibers a sort of glue for the bacteria also make it an attractive material for microbial engineers.

To create their living material, the researchers first worked out a way to engineer the bacterium E. coli to produce an entirely biological ink that could be used to 3D print solid structures. The scientists began by culturing genetically engineered E. coli in a flask, feeding the bacteria nutrients so that they multiplied and, as they divided, produced the Curli fiber polymers.

The researchers then filtered out the gelatinous polymers to form a microbial ink that could be fed into a 3D printer. While using microbes to make 3D printable inks is not new in itself, what sets this particular microbial ink apart is that it is 100 percent biological and not blended with any other substances.

Testing the living material

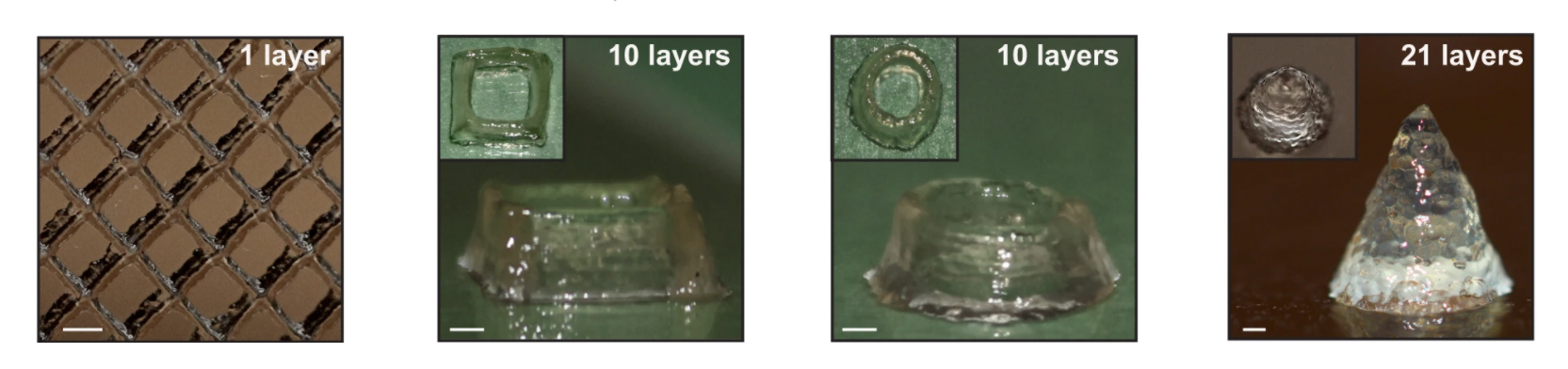

The Northeastern team used the gelatinous material to print small objects in the shape of a circle, square, and cone. The aim of the project is to use the material’s living cells as “factories” to make materials with specific attributes, such as those that could be useful in medicine.

“Think about it as a platform for building many different things, not just bricks for buildings or construction,” said Joshi, who compares the team’s work to how polymer chemists devise plastic materials with various distinct purposes. “Biology is able to do similar things. Think about the difference between hair, which is flexible, and horns on a deer or a rhino or something. They’re made of similar materials, but they have very different functions.

“Biology has figured out how to tune those mechanical properties using a limited set of building blocks.”

Due to the material being “alive”, it can do what living things do, said Manjula-Basavanna, a postdoctoral fellow in Joshi’s laboratory. For example, the material is capable of healing itself, the way skin does, and in the right conditions, the cells within the microbial gel could simply make more of themselves. However, the material is not necessarily always growing.

“If you were to take [the] whole cone and dunk it into some glucose solution, the cells would eat that glucose and they would make more of that fiber and grow the cone into something bigger,” explained Joshi. “There is the option to leverage the fact that there are living cells there. But you can also just kill the cells and use it as an inert material.”

While the initial gel is made entirely from genetically engineered E. coli, the Northeastern team also experimented with mixing the ink with other genetically engineered microbes to create different 3D printing materials.

Through their experiments, the team fabricated a material capable of delivering an anti-cancer drug when it encounters a specific chemical stimulus, and a material that can trap the toxic chemical Bisphenol A from its surrounding environment.

While the study is so far a proof-of-concept, Joshi believes the microbial ink could pave the way for a whole range of possibilities for building things with biology. For instance, the material could have potential uses for constructing off-space habitats and their components, as well as numerous medical applications.

“If there is a way to manufacture in a more sustainable manner, it’s going to involve using living cells,” Joshi said. “This is advancing more towards that type of paradigm of building things with living cells.”

Further information on the study can be found in the paper titled: “Programmable microbial ink for 3D printing of living materials produced from genetically engineered protein nanofibers,” published in the Nature Communications journal. The study is co-authored by A. Duraj-Thatte, A. Manjula-Basavanna, J. Rutledge, J. Xia, S. Hassan, A. Sourlis, A. Rubio, A. Lesha, M. Zenkl, A. Kan, D. Weitz, Y. Zhang, N. Joshi.

Subscribe to the 3D Printing Industry newsletter for the latest news in additive manufacturing. You can also stay connected by following us on Twitter and liking us on Facebook.

Looking for a career in additive manufacturing? Visit 3D Printing Jobs for a selection of roles in the industry.

Subscribe to our YouTube channel for the latest 3D printing video shorts, reviews and webinar replays.

Featured image shows Neel Joshi, associate professor of chemistry and chemical biology, and Avinash Manjula-Basavanna, a postdoctoral researcher, work on programmable microbial ink for 3D printing of living materials, in the Mugar Life Sciences building. Photo by Matthew Modoono/Northeastern University.