Scientists from the University of New South Wales (UNSW) have developed a novel technique to 3D print bone-mimicking structures containing living cells, which could have potential uses for bone tissue engineering applications, disease modeling, and drug screening.

Most significantly, the method could enable in-situ reconstruction of bone and cartilage defects by extruding the ceramic-based ink directly into the affected area, a feat that until now has not been achieved by other technologies, according to Associate Professor Kristopher Kilian.

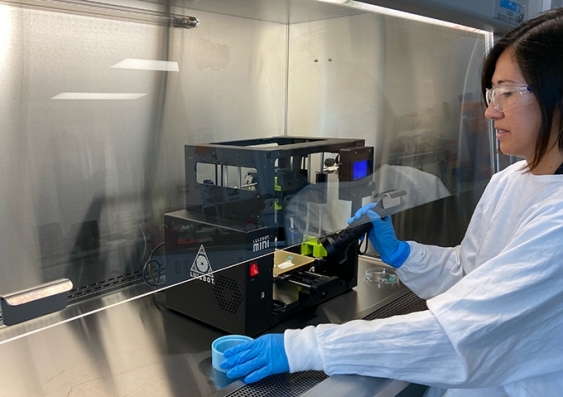

Kilian co-developed the breakthrough with Dr. Iman Roohani of UNSW’s School of Chemistry, which facilitates the printing of cell-laden “bone” at room temperature for the first time.

“This is a unique technology that can produce structures that closely mimic bone tissue,” said Roohani. “It could be used in clinical applications where there is a large demand for in-situ repair of bone defects such as those caused by trauma, cancer, or where a big chunk of tissue is resected.”

Ceramic omnidirectional bioprinting

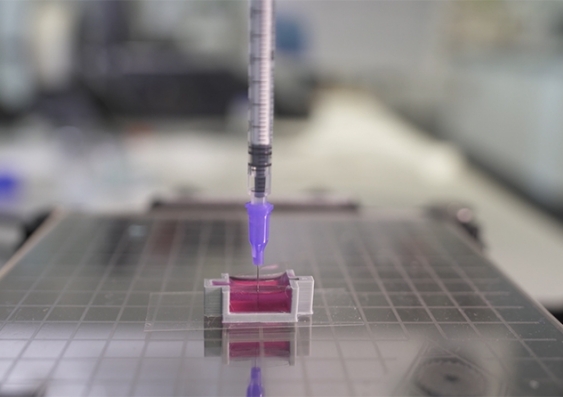

Kilian and Rohaani’s new technique, named ceramic omnidirectional bioprinting in cell-suspensions (COBICS), uses a 3D printer to deploy a novel ceramic-based ink made up of calcium phosphate to produce bone-like structures that harden in minutes when they are placed in water.

“The ink takes advantage of a setting mechanism through the local nanocrystallization of its components in aqueous environments, converting the inorganic ink to mechanically interlocked bone apatite nanocrystals,” Roohani explained. “In other words, it forms a structure that is chemically similar to bone-building blocks. The ink is formulated in such a way that the conversion is quick, non-toxic in a biological environment and it only initiates when ink is exposed to the body fluids, providing an ample working time for the end-user, for example, surgeons.”

When this ink is combined with a collagen substance containing living cells, in-situ fabrication of bone-like tissues is enabled. The process is able to occur at room temperature, making it unique from other 3D printed bone-mimicking techniques. Additionally, the fact that living cells can be part of the 3D printed structure, rather than the material being first constructed in a laboratory using high-temperature furnaces and harsh chemicals before living cells are added to it, makes the new method even more unique.

“The cool thing about our technique is you can just extrude it directly into a place where there are cells, like a cavity in a patient’s bone,” said Kilian. “We can go directly into the bone where there are cells, blood vessels, and fat, and print a bone-like structure that already contains living cells, right in that area. There are currently no technologies that can do that directly.”

A new way of repairing bone tissue

According to the scientists, a number of surgeons and medical technology manufacturers have already shown interest in the method, which Kilian believes could open up a brand new way of treating and repairing bone tissue.

“This advance really paves the way for numerous opportunities that we believe could prove transformational – from using the ink to create bone in the lab for disease modeling, as a bioactive material for dental restoration, to direct bone reconstruction in a patient,” he said. “I imagine a day where a patient needing a bone graft can walk into a clinic where the anatomical structure of their bone is imaged, translated to a 3D printer, and directly printed into the cavity with their own cells.

“This has the potential to radically change current practice, reducing patient suffering and ultimately saving lives.”

The next step for the scientists is to perform in-vivo tests in animal models to observe whether the living cells in the bone-mimicking structures continue to grow after being implanted in bone tissue.

More information on the scientists’ work can be found in the paper titled “Synthetic bone-like structures through omnidirectional ceramic bioprinting in cells suspensions”, published in the Advanced Functional Materials journal. The paper is co-authored by S. Romanazzo, T. Molley, S. Nemec, K. Lin, R. Sheikh, J. Gooding, B. Wan, Q. Li, K. Kilian, and I. Roohani.

Advances in bioprinting bone

3D printed biostructures have become the focus of a plethora of research projects and initiatives in recent years, particularly in the fields of tissue engineering and regenerative medicine. New bioinks are being continually developed for these applications, and 3D printing is being combined with techniques like biomaterial engineering and stem cell biology to create an even wider range of customizable bone grafting materials.

In the last year, researchers from Oregon Health & Science University (OHSU) have investigated how 3D printed lego-style ‘bone bricks’ could heal broken skeletal tissue, while another collaborative research project explored how 3D bioprinted nanocomposite scaffolds could facilitate bone formation. Elsewhere, Skoltech scientists simulated a method of 3D printing personalized ceramic bone implants using functional representation modeling (FRep).

Most recently, a team from the Delft University of Technology constructed temporary bone implants from biodegradable porous iron using their own purpose-built extrusion-based setup. The next stage for their research involves the infusions of nanobioceramics to promote bone growth and the integration of antibacterial agents to reduce infection risk.

Subscribe to the 3D Printing Industry newsletter for the latest news in additive manufacturing. You can also stay connected by following us on Twitter and liking us on Facebook.

Be sure to subscribe to the Another Dimension podcast on your chosen podcast player to make sure you never miss an episode.

Looking for a career in additive manufacturing? Visit 3D Printing Jobs for a selection of roles in the industry.

Featured image shows scientists have worked out how to print bone-like structures using a 3D-printer and a gelatinous ‘bath’ containing living cells. Image via UNSW.