3D printing with conveyor belts has seen a flurry of activity this year. Now, Bill Steele of Polar3D has posted several interesting videos featuring new 3D printers.

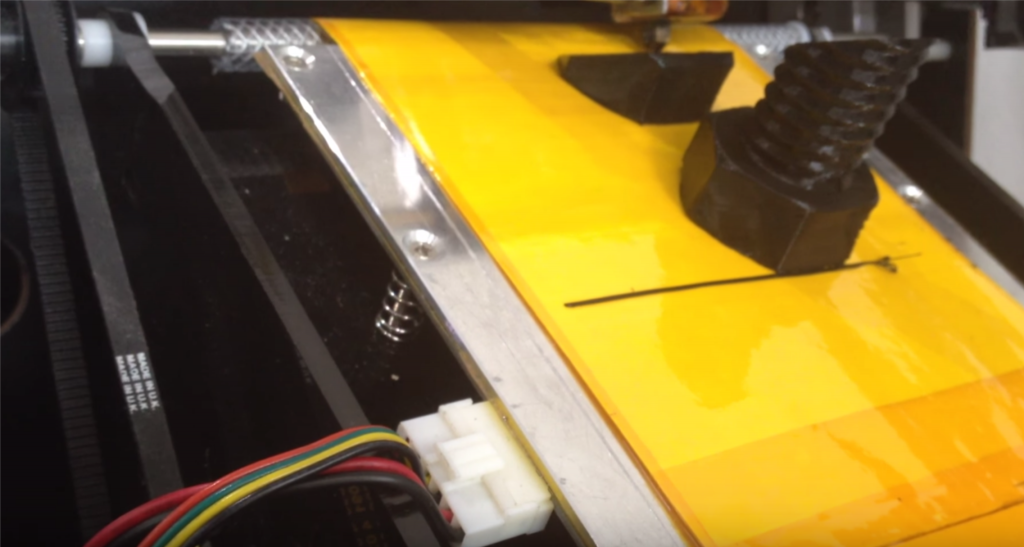

The Polar3D Flash FDM printer uses a conveyor tilted at an angle to produce a continuous stream of parts. In the video the print head moves in the X and Y axis, as in any cartesian FDM machine, however the Z axis is a conveyor belt – angled at 45°.

Another video posted this week shows a 3D printer Steele calls the Printrbot Printrbelt. This machine is the result of a partnership between Polar 3D and Printrbot.

Brook Drumm from Printrbot demonstrated the Printrbelt ahead of sending it down to the machines first public demonstration at the International Society for Technology in Education (ISTE) event in Texas earlier this week.

The Printrbelt’s printhead moves on an X axis angled at 35° to the Z axis composed of a heated print bed conveyor belt. Drumm got in touch to tell use, “It’s out of beta and for sale for early adopters who want to get on that bleeding edge.”

The Printrbelt also features automatic part ejection.

A brief history of conveyor belt 3D printers

Combining 3D printers with conveyor belts has a relatively long history – by tech standards at least. In 2010, MakerBot published the files for a CupCake add on. The automated build platform was designed by Charles Pax.

Conveyor belts have also appeared on industrial level 3D printers. In 2012 we reported on the Voxeljet VXC800 3D printer, a machine that made its debut at Euromold. The concept was introduced in 2011.

At last year’s Formnext in Frankfurt, BigRep’s René Gurka told us about his plans to work with TNO on the Print Valley project. First seen in 2012, Print Valley – aka the Sushi 3D printer – shows rapid additive manufacturing on a conveyor belt.

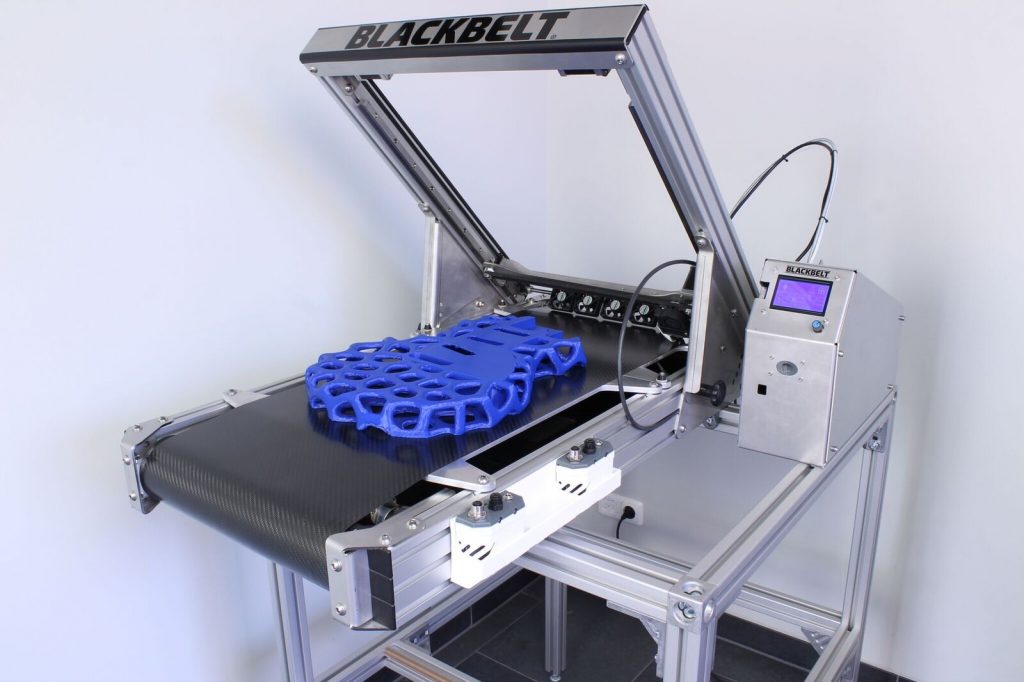

The Blackbelt 3D printer and Stratasys Continuous Build 3D Demonstrator

More recently 3D Printing Industry reported on the Blackbelt 3D printer.

The Blackbelt 3D prints at 45° and can be adjusted to print at adjusted to run at 15°, 25° or 34°. The 3D printer was created by Stephan Schürmann and uses 3 FDM printheads. The company is set to close a successful Kickstarter campaign tomorrow, having beaten the funding goal by almost €40,000. Early backers were able to purchase a Blackbelt 3D printer for €5,500, the final retail price will be €9,500.

In the same week, Stratasys unveiled their latest technology demonstrator – the Continuous Build 3D. At RAPID this year I watched Scott Crump – the inventor of FDM 3D printing and Chief Innovation Office at Stratasys – pull back a curtain to reveal 9 3D printers stacked in a 3×3 configuration.

The Continuous Build 3D Demonstrator is based on the Fortus engine and 3D prints onto a plastic film, once the print is complete a conveyor belt moves the print past a cutting tool that snips off the print and ejects it in a waiting basket.

Crump describes the Continuous Build 3D Demonstrator as an, “important milestone in the company’s long term vision to make additive manufacturing a viable solution for volume production environments.”

The Printrbot Printrbelt and Polar3D Flash FDM machines appear to be at an earlier stage of development. Functional prototypes can be seen working online, but as Brook Drumm says in his video, “We’ve only got it moving, we’re sending it down to Bill [Steele] to get all the software dialled in.”

Printrbot writes, “It is a beta, but too fun to keep to ourselves.” We’re looking forward to seeing how the 3D printers progress and will bring you more news as we have it. To be the first with all the latest 3D printing news, subscribe to our free newsletter and follow our active social media channels.

Featured image shows Printrbot’s Brook Drumm previewing the Printrbot Printrbelt 3D printer.