Arizona-based engineering and 3D printing service provider Phoenix Analysis & Design Technologies (PADT) has announced that NASA is further funding its collaboration with Arizona State University (ASU) and Kennesaw State University (KSU) to develop stronger and lighter structures for space exploration using 3D printing and simulation.

The funding comprises a $755,000 2019 Phase II Small Business Technology Transfer (STTR) awarded by NASA. The grant is intended to help the group develop a software tool for designing, virtually testing and 3D printing strong, lightweight, bio-inspired lattice structures for aerospace vehicles. At the end of the research project, PADT aims to have created a commercial software product that it can market to the aerospace industry.

“This research project is a great example of government, academic institutions and the private sector working together to provide practical solutions for the space industry,” states Ji Mi Choi, associate vice president, Entrepreneurship and Innovation, Arizona State University.

“We appreciate the opportunity to work with NASA, PADT and KSU as we discover new ways to apply 3D printing and simulation to real-world challenges.”

PADT and ASUs 3D printing partnership

NASA’s Phase II STTR grant is a continuation of an original $127,000 Phase I grant it awarded to PADT and ASU in 2018. The Phase I grant supported PADT and ASU in their initial research into the development of bioinspired 3D printed structures for creating strong and lightweight spacecraft parts. This is PADT’s 16th STTR/SBIR grant since the company was founded in 1994. The firm’s primary line of work involves helping customers develop physical products by providing numerical simulation, product development, and rapid prototyping products and services.

“We’re proud to win this Phase II STTR because it furthers our coordination with the Fulton Schools and requires the use of our three main areas of expertise: 3D printing, simulation and product development,” comments Alex Grishin, Ph.D., consulting engineer, PADT. “Improving aerospace innovation is always an exciting prospect, and our team is uniquely qualified to apply our expertise to develop disruptive technology for NASA.”

PADT and ASU have also collaborated in a separate project to advance post-processing methods for additive manufacturing. The two partners are also working alongside high-pressure technology specialist Quintus Technologies, and Phoenix Heat Treating, a provider of metal heat treatments in the project. This project is also federally funded, having been awarded $2.4m in 2018 and a further $800,000 in matching funds in 2019 from national additive manufacturing accelerator America Makes.

3D printing inspired by nature

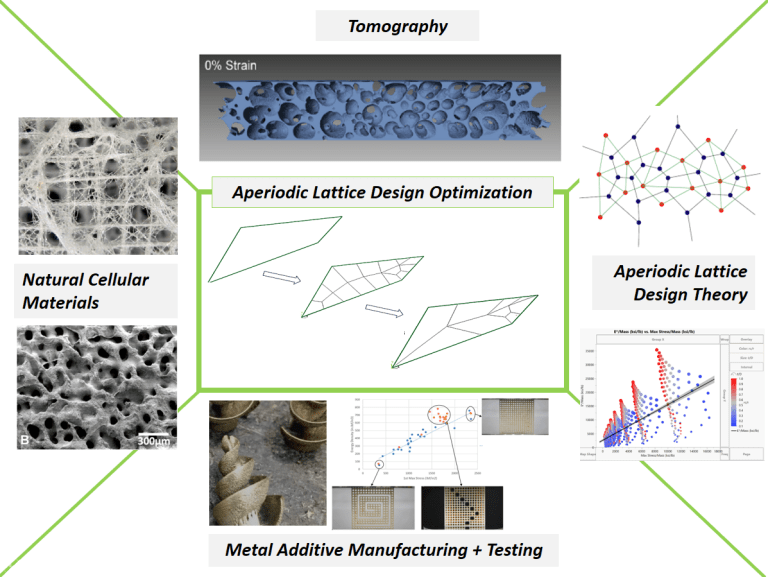

PADT, ASU and KSU’s aerospace project is focused on shapes found in nature as objects like beehives, with an internal honeycomb structure, provide adequate strength whilst remaining lightweight. Furthermore, the shapes of these honeycomb or lattice structures are not required to be uniform in design. With uneven spacing, varied compositions can be utilized to provide better performance for an aerospace component.

As such, PADT, ASU and KSU are focused on developing a design tool that combines concepts from density, topology and parameter optimization to generate irregular lattice materials, without a defined cell size. Using 3D printing, the bio-inspired structures created in the software tool can then be manufactured in detail, to a degree not possible with other technologies.

In the future, NASA itself may use the lattice structure design tool to 3D print high-performance components for its spacecrafts, including items like heat shields, acoustic liners, space debris resistant skins, lightweight panels and heat exchangers. “The NASA Phase II STTR grant allows us to use simulation and 3D printing to explore bio-inspired structures to innovate how NASA designs and manufactures its spacecrafts,” explains Kyle Squires, Ph.D., dean, Fulton Schools of Engineering, Arizona State University.

As well as developing a software tool, the group is also providing cellular material data for inclusion in NASA’s open-source Periodic Table of Life (PeTaL) platform, a database and data analytics tool focused on nature-inspired solutions to human design challenges. The data will also be used for NASA’s 3D printed metal demonstration artifacts.

Subscribe to the 3D Printing Industry newsletter for the latest news in additive manufacturing. You can also stay connected by following us on Twitter and liking us on Facebook.

Looking for a career in additive manufacturing? Visit 3D Printing Jobs for a selection of roles in the industry.

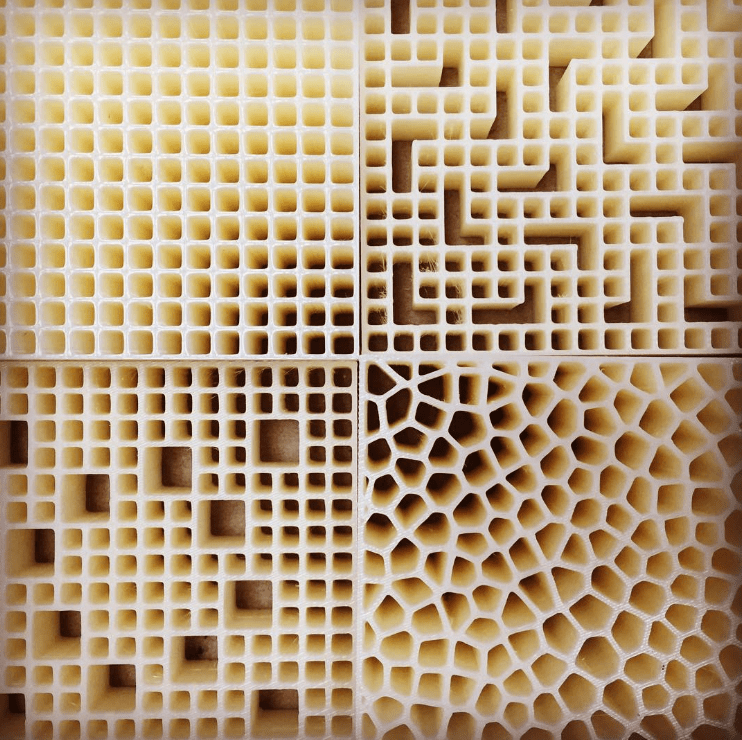

Featured image shows honeycomb mold. Photo via Pranav Kumar Jain/Unsplash.