NASA’s Marshall Space Flight Center (MSFC) in Huntsville, Alabama, has become the first commercial customer of the 7A77 aluminum 3D printing powder, developed by the HRL Laboratories research center. Coming just one week after the material was made commercially available, 7A77 was sold by HRL Additive, a newly established 3D printing outfit from HRL Laboratories that aims to provide the powder to customers in the aerospace and automotive sectors.

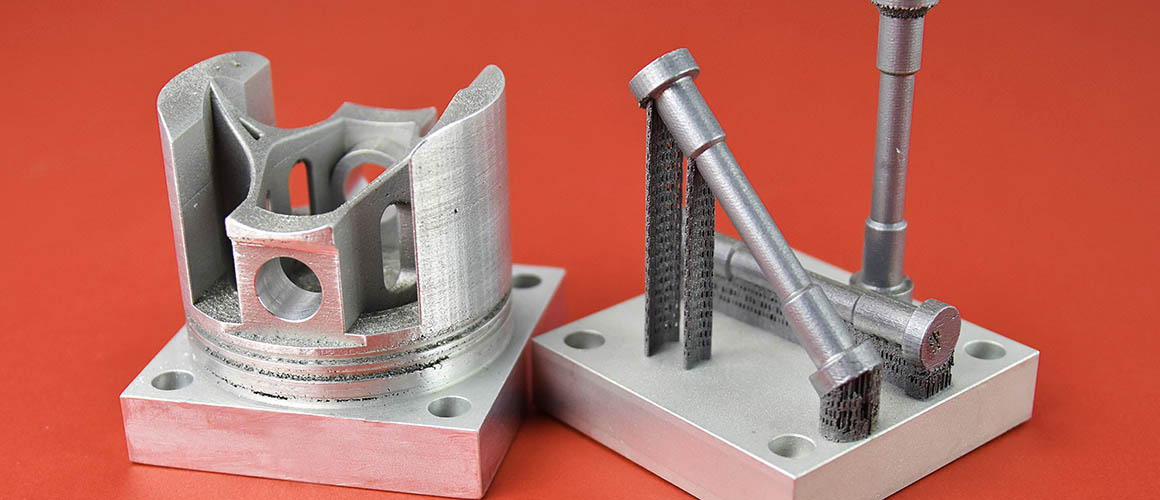

Using 7A77, MSFC aims to explore the potential of 3D printing print large-scale components: “Certainly, the 7A77 feedstock powder could unlock the production of large-scale components produced via fusion-based additive manufacturing,” explained Omar Rodriguez of NASA’s Marshall Space Flight Center.

History of the 3D printing 7A77 powder

HRL Laboratories is a research facility co-owned by American multinational vehicle manufacturer General Motors, and the Boeing aerospace corporation. The center specializes in research into microelectronics, information & systems sciences, materials, sensors, and photonics.

Development of the 7A77 aluminum powder has been taking place at HRL since 2014. The researchers set about creating a 3D printable version of Al-7075, a traditionally non-weldable and commonly used aluminium alloy for high-stress structural applications.

Al-7075 is known for its high strength, toughness and corrosion resistance, however is not processable with 3D printing due to its susceptibility to embrittlement. By making it compatible with additive manufacturing, the HRL research team sought to expand its applications across high value sectors including aerospace, automotive and oil & gas.

Three years later, in September 2017, HRL published a paper demonstrating its success in 3D printing a weldable version of Al-7075, which came to be known as Aluminum 7A77.60L. Then, seeking to commercialize the powder, HRL announced in 2019 that 7A77 had become the first additive manufacturing aluminum alloy registered with the historic Aluminum Association.

Customers are now able to purchase the 7A77 aluminum powder from HRL. It can be used with standard “off-the-shelf” 3D printers, according to the research center. Zak Eckel for HRL Additive comments: “Our goal is to provide the highest quality powder to HRL’s LLC members in the aerospace and automotive industries, as well as other commercial customers.”

Developing large-scale aerospace components at NASA

Having purchased the 7A77 aluminum feedstock powder, MSFC plans to conduct research around the material with the potential of incorporating it into the production of large-scale aerospace components via fusion-based additive manufacturing. The center will 3D print different sized test parts with the powder before subjecting them to rigorous assessment.

“Printed test articles will be subjected to a comprehensive characterization regime expanding several length-scales,” adds Rodriguez. “The end-goal of this research effort is to expand MSFC’s range of fusion-based additive feedstock materials.”

“If successful in our research endeavor, the feedstock powder could be part of the aerospace-related assets produced at the planned large-scale, advanced manufacturing facility.”

NASA MSFC has a long history of developing additive manufacturing for aerospace. A team from the center recently developed and 3D printed a new copper-based alloy, called GRCop-42, for use in rocket propulsion components. MSFC also helped to test a 3D printed combustion chamber for a rocket engine, which was made using copper.

Subscribe to the 3D Printing Industry newsletter for the latest news in additive manufacturing. You can also stay connected by following us on Twitter and liking us on Facebook.

Looking for a career in additive manufacturing? Visit 3D Printing Jobs for a selection of roles in the industry.

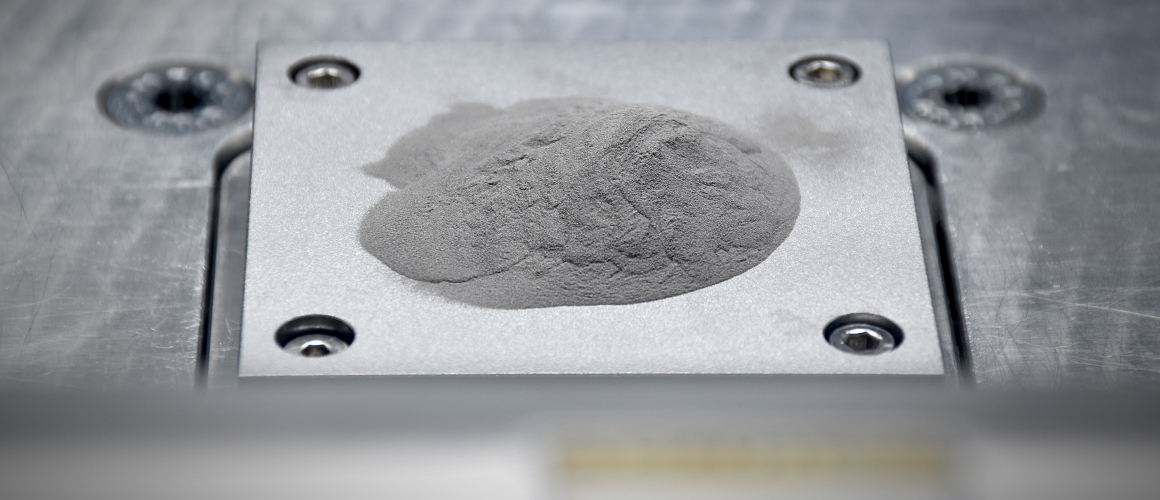

Featured image shows Aluminum 7A77.60L powder from HRL. Photo via HRL Laboratories.