Polish 3D printer manufacturer 3DGence has partnered with advanced material companies Arkema and Armor Group to make its ESM-10 (Engineering Soluble Material) compatible with the Kimya PEKK-A high performance material. The partnership between the three companies aims to expand the use of open-market applications for PAEK based materials in 3D printing.

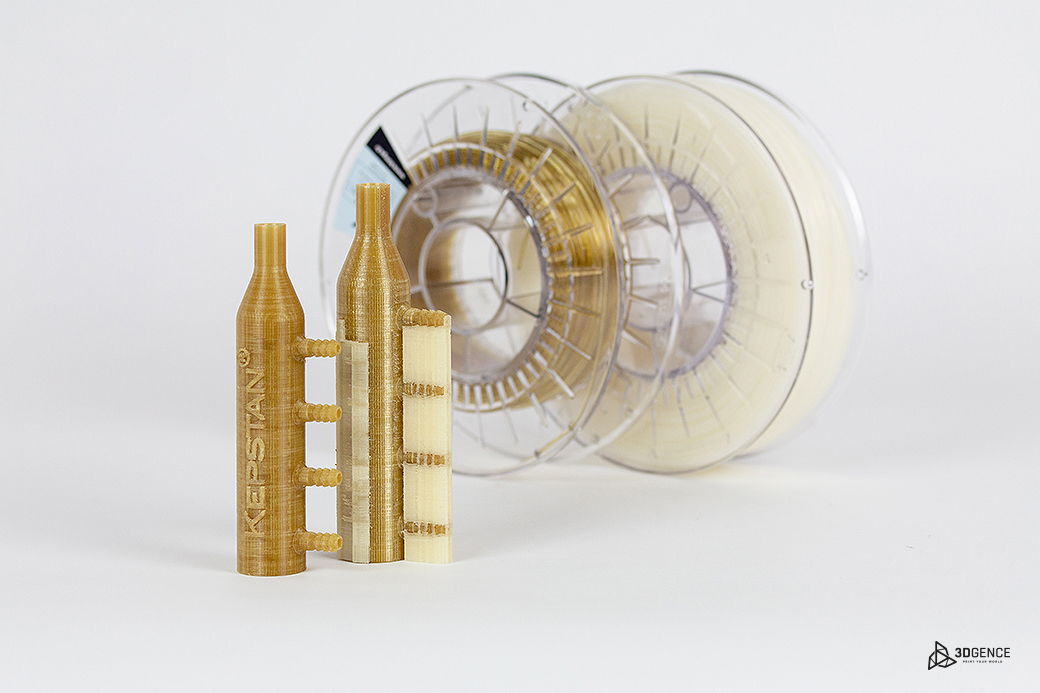

PEKK-A, developed by Armor Group’s filament brand Kimya, and based on the Kepstan PEKK Resin from French advanced materials company Arkema, is now available on 3DGence’s Certified Material Base. Users can 3D print Kimya PEKK-A material with the ESM-10 soluble support on 3DGence’s INDUSTRY F340 FFF/FDM 3D printer.

“3DGence’s collaboration with Arkema and Armor Group is a major breakthrough for the Industrial 3D Printing Global Market,” comments Mateusz Sidorowicz, Marketing Manager from 3DGence.

“Adding this new material profile for use on the 3DGence INDUSTRY F340 will allow enterprises from Aerospace, Automotive, and many other industries to produce complex parts from PEKK.”

Supporting PAEK 3D printing

Founded in 1922, the Armor Group specializes in producing advanced and custom print and coatings materials for various industries. The company has seven different divisions through which it offers industrial coding and printing, office printing, films and inks. Armor launched Kimya in order to provide filaments for the additive manufacturing industry.

Kimya’s PEKK-A filament is designed for technical applications requiring a high resistance to temperature (up to 260 ° C). It is also flame retardant, receiving a V0 classification on the UL94 plastics flammability standard, which denotes that the material stops burning within 10 seconds.

However, in order to 3D print with high-temperature, high-strength materials like PEKK-A, a suitable soluble support material is required for more complex geometries and higher resolutions. Released at the end of 2018, 3DGence’s ESM-10 filament is intended to provide support for the high-performance PAEK polymers as well as prototyping materials like ABS.

Using dedicated cleaning stations, the ESM-10 filament automatically dissolves, allowing for the creation of complex 3D prints with easy support removal. Its suitability towards high-performing, technical PAEK materials lies in its heat resistance, where it can remain stable in a heated chamber with temperatures ranging around 80°C. Working with Armor and Arkema, 3DGence’s ESM-10 can now be used for additional PEKK applications on the F340 3D printer.

Pierre-Antoine Pluvinage, Business Development Director from Armor Group, Kimya Business Division, explains that “Developing new solutions is an integral part of any manufacturing company’s strategy. We are glad that we could support 3DGence with our knowledge and experience. It has resulted in the creation of a new technological project based on additive manufacturing and now custom material like PEKK can work with reliable 3D printer from 3DGence.”

Bringing PAEK to desktop 3D printing

Many other 3D printing companies have also taken steps towards expanding the use of PAEK filaments in additive manufacturing. For example, British OEM E3D Online has developed a range of products for high-temperature 3D printing in order to bring the engineering-grade PAEK filament to desktop 3D printers. The products released include a hotend heater cartridge and heater bed, developed to help FDM/FFF machines maintain the temperature requirements to print PAEK.

Furthermore, Victrex, a UK-headquartered performance plastics developer, confirmed its intention to invest millions of Euros in Dutch 3D printer and software developer Bond 3D. With the investment, the company aims to develop new applications and commercialize PEEK and PAEK polymer products for 3D printing.

Subscribe to the 3D Printing Industry newsletter for the latest news in additive manufacturing. You can also stay connected by following us on Twitter and liking us on Facebook.

Looking for a career in additive manufacturing? Visit 3D Printing Jobs for a selection of roles in the industry.

Featured image shows PEKK-A filament and 3D printed sample. Photo via 3DGence.