Scientists at the Barcelona Institute of Science and Technology (BIST) have published a new research paper, showing a way to 3D print colored objects using SLS printers.

The technology discussed in the paper shows the possibility of mixing polymer powders with commercial inks to enable on-demand 3D color printing using inkjet based methods by introducing nano materials.

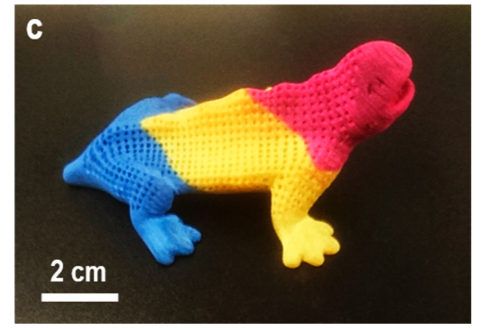

Gold nanorods (GNR) were used as nanoengineered photothermal synthesizers (NEPS) to make a powdered material suitable for selective laser sintering. The powders were then mixed with commercial dyes to make colored nanocomposites. Finally, these colored nanocomposites were used to 3D print a colorful dragon.

The current commercially available SLS 3D printing systems can produce only black, gray and white objects. HP plans to bring color 3D printing to market with the Jet Fusion 300 / 500 series to power-based Multi Jet Fusion. Various degrees of color 3D printing are available with Fused Deposition Modeling (FDM) and other printing methods such as binder jetting, material jetting, sheet lamination processing. However, coloration of SLS 3D prints is typically performed during post-processing.

Colored 3D printing powders

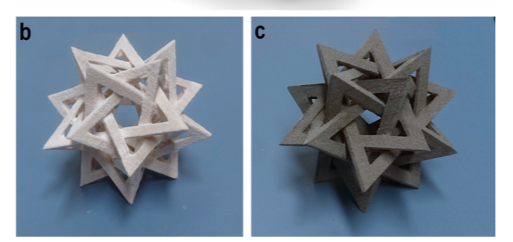

The BIST researchers produced two powders, one polyamide (PA12) powder mixed with GNR and other mixed with carbon, an industry standard. To test the results, two complex shaped identical objects were sintered with 1 W 808 nm diode laser. The GNR powder produced a white object ready for post-processing. The researchers found that such composites had “improved light-to-heat conversion compared with equivalent composites using the industry standard carbon black as a sensitizer and could be sintered using low-power light sources. Additionally, “they appear much whiter and can produce brightly colored 3D objects when mixed with dyes. Our results open a new route to utilize plasmonic nanoparticles to produce colorful and functional 3D-printed objects.”

GNR were used for its cost and energy efficiency. They can be produced in large batches at a low cost and can reach a given temperature more quickly than carbon-based sensitizers.

“The utilization of resonant nanoparticles in additive manufacturing allows for near complete control over the visual and photothermal properties of 3DP materials and opens the door to color-on-demand powder-based 3D printing.”

The researchers concluded, “the use of NEPS allows for customization of the photothermal and spectral response of both the composites and the final printed objects, and this could lead to improved efficiency and opportunities to use new types of light sources for additive manufacturing”

Full color 3D printers

Many companies are in a race to master the on-demand color 3D printing technology. The forthcoming HP system may find a market who require a color 3D printing solution, while ongoing updates and expansion of the materials palette available on the Stratasys J750 give very impressive results. Also notable is the Mimaki 3DUJ-553 3D printer. On a longer time horizon is a potential device from Apple, in January 2018 Apple was granted a US patent for a full color 3D printer.

The research paper titled “White and Brightly Colored 3D Printing Based on Resonant Photothermal Sensitizers” was co-authored by Alexander W. Powell, Alexandros Stavrinadis, Ignacio de Miguel, Gerasimos Konstantatos, and Romain Quidant.

For more news relating to 3D printing, subscribe to our 3D printing newsletter, or follow us on Facebook and Twitter. If you are looking for an exciting career, visit our 3D printing job site.

Featured image shows the 3D printed colored dragon made during the research. Photo via American Chemical Society