London-based 3D content platform MyMiniFactory has launched a new customizer tool which allows its users to personalise 3D printable models.

Currently in beta, the Customizer allows designers to create what the company calls “customizer worlds” for their uploaded models. Consisting of interchangeable part options for the user to sift through and select from, the customizer world can be created by designers without the need for coding on their end. The company has designed the in-browser tool software so that consumers are able to 3D print their customized model using a single STL file as well.

With the Customizer beta 1.0, MyMiniFactory is aiming to respond to the demand from makers and designers for an easy way to create customized 3D model options. Adrian Delgado, Lead Customizer Developer at MyMiniFactory, stated:

“The focus of the customizer is on the designer and maker experience.”

“Many designers want to have customized options for their makers to pick and choose from but unless they’re willing to code the entire environment, customization is a fairly dry experience showcased primarily using photos. Now if designers want a customizer they don’t need to write code for one.”

Building the 3D model customizer

Prior to the launch of its customizer tool, MyMiniFactory identified the limitation makers experienced with their original models. This was especially true for those who did not use CAD software, or for makers that did not have permission from the original designers to alter the model.

Furthermore, 3D designers also create additional models that incorporate varying components and interchangeable pieces. To assemble the parts together, users are forced to use glue, which can prove difficult especially when considering the size and fitting of the 3D printed model.

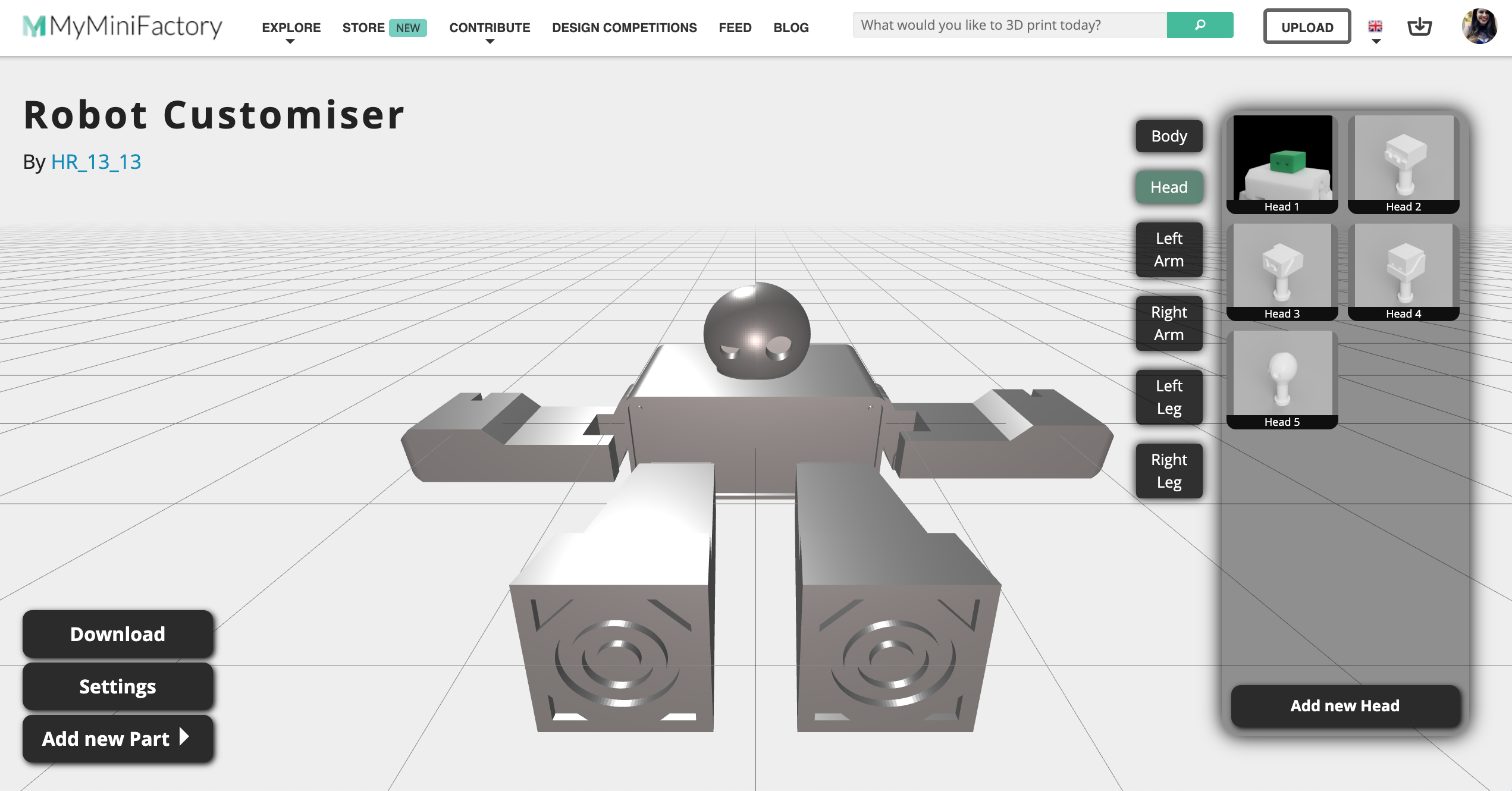

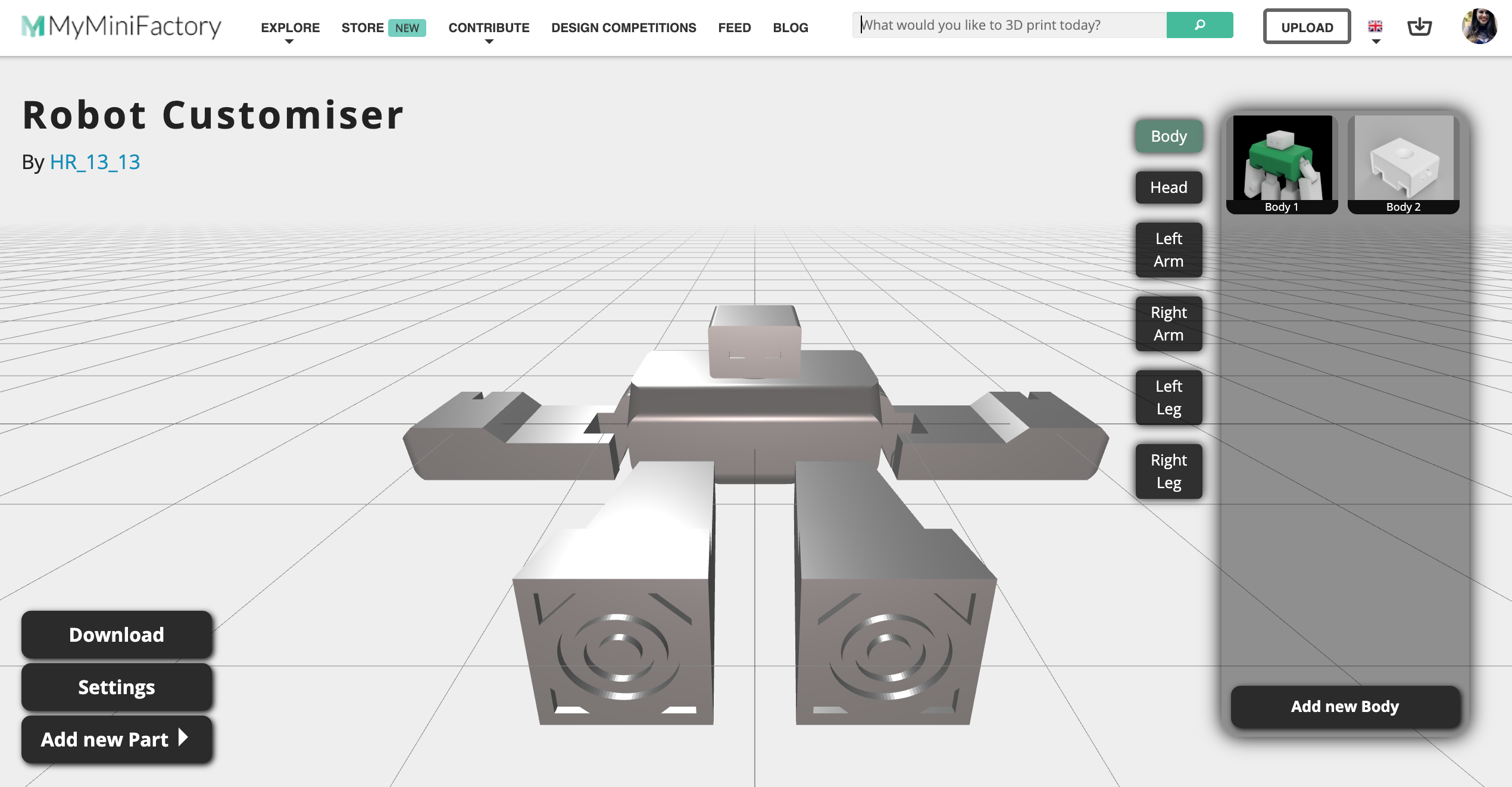

As a result, MyMiniFactory has designed the Customizer, with the intention of providing an interactive and user-friendly experience for 3D printable model customization. The tool operates through a functional user interface allowing consumers to select and preview different components for each customizable part of the 3D model.

A customised world

3D designers create their customizer world by defining what parts they want included, and how they can be interchanged. Once they are happy with their 3D model and exchangeable components, designers are told to request the particular environment and settings from the customizer team at MyMiniFactory. The team will then create the designer’s customizer world for them. All that’s left of the designer is to upload each interchangeable part separately into the environment, after which the customizer can then be published. Significantly, the process for creating the tool eliminates the need for the designer to engage in any form of coding or technical positioning.

The software for the customizer tool has been developed to automatically adapt to changes in a model with structural adjustments and relative positioning. The parts are therefore ensured to fit together without the need for designers to modify an entire model for a single part change, as well as rendering transition fits obsolete. Users downloading the file therefore gain the benefit of downloading the 3D model as a single STL file generated and constructed in the customizer software.

MyMiniFactory Click & Print

Other tools the company has developed to help simplify the 3D printing process includes its Click & Print plugin developed in collaboration with OctoPrint, an open source interface used to control and monitor many aspects of print runs. The plugin allows users to 3D print without prior knowledge of slicing or STL file preparation.

MMF’s Click & Print feature has also been integrated within the Thunder desktop 3D printer from Chinese 3D printer manufacturer BIQU, helping to ease the system’s file preparation procedure, while making the technology more accessible to its customers.

Subscribe to the 3D Printing Industry newsletter for the latest news in additive manufacturing. You can also stay connected by following us on Twitter and liking us on Facebook.

Looking for a career in additive manufacturing? Visit 3D Printing Jobs for a selection of roles in the industry.

Featured image shows MMF’s customizer tool, showcasing the different options for the head part of the robot. Image via MyMiniFactory.