As seen from the highly efficient 3D printed batteries at Carnegie Mellon University (CMU) and Missouri University of Science and Technology, the October 2018 edition of ScienceDirect’s Additive Manufacturing journal is now in progress.

Volume 23 currently includes the work of 9 innovative research groups from leading institutions all around the world, including projects from the Fraunhofer Institute for Laser Technology (ILT), the University of Cádiz and the Johannes Kepler University Linz (JVU).

From the strengths of 3D printed parts for motorsports, through to Polymeric Pellet-Based Additive Manufacturing (PPBAM) for the navy, we take a look at a selection of the projects on the cutting edge of 3D printing research.

Modifiable scandium

The prevalence of scandium-aluminum alloy has risen in recent years due to its outstanding strength to weight ratio, and a newfound ability to process the rare metal whit little wastage.

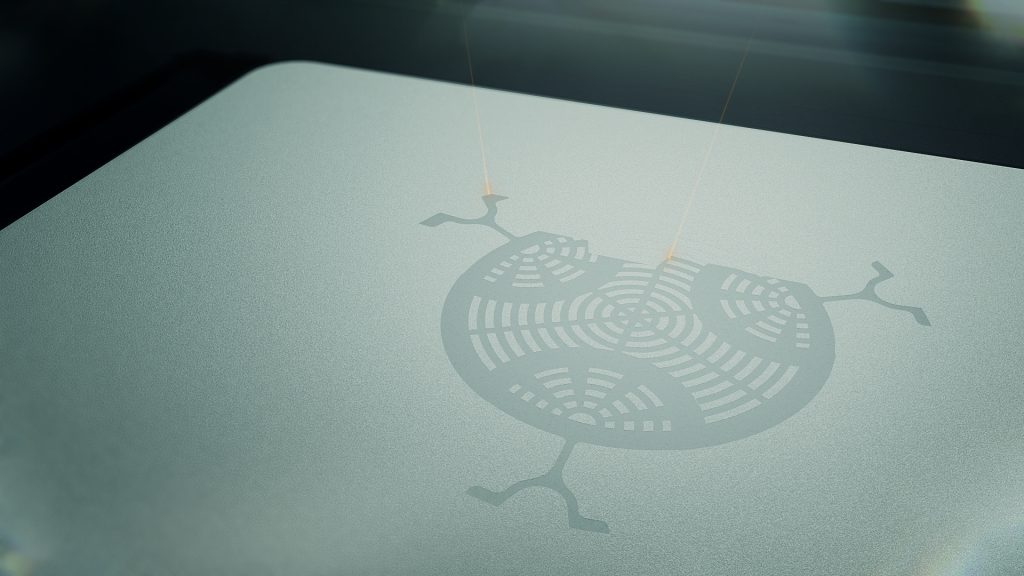

In a collaboration between Nanjing University of Aeronautics and Astronautics and the Fraunhofer ILT, researchers have successfully 3D printed a high performance scandium/aluminum alloy.

Processed used selective laser melting (SLM) technology, the research demonstrates the potential to tailor an Al-Mg-Sc-Zr with desired properties.

“Selective laser melting of rare earth element Sc modified aluminum alloy: Thermodynamics of precipitation behavior and its influence on mechanical properties” is co-authored by Han Zhang, Dongdong Gu, Jiankai Yang, Donghua Dai, Tong Zhao, Chen Hong, Andres Gasser and Reinhart Poprawe.

An alternative to non-destructive testing

At the University of Liverpool in the UK, researchers argue that residual stresses inside additive manufactured parts should not be overlooked.

In the paper, hole drilling and contour methods are given as a more cost effective alternative to non-destructive testing.

The supporting paper for this research is titled “Determination of the effect of scan strategy on residual stress in laser powder bed fusion additive manufacturing“, and available to read open access under a creative commons license. It is co-authored by J. Robinson, I. Ashton, P. Fox, E. Jones and C. Sutcliffe.

Achieving a competitive edge

Researchers from JVU, Austria, have conducted a study on additive manufacturing for lightweight structures.

The study compares the properties of two motocross bike seats 3D printed on EOS P396 and EOS P770 polymer systems

“In summary,” the conclusion states, “the results show that non-homogeneous, system-specific, and anisotropic material properties depending on position and wall thickness have to be considered for structural analysis of parts additive manufactured by laser sintering.”

The full research article, “Thickness dependency of mechanical properties of laser-sintered polyamide lightweight structures” can be accessed here. It is co-authored by David Tasch, Anna Mad, Robert Stadlbauer and Martin Schagerl.

3D printing at sea

Remember Navantia’s 3D printed toilet cubicle? In Additive Manufacturing v.23, the University of Cádiz is presenting its findings from this large scale project that it performed for the Spanish Ship Builder.

The 3DCabin, as it is known, is presented in the study alongside two other large-scale 3D printed samples as a proof of concept for development of PPBAM additive manufacturing system.

The development is part of Navantia’s “Shipyard 4.0” initiative to reduce the cost and lead time of its marine product, and increase quality towards more sustainable manufacturing methods.

All nine articles in Additive Manufacturing Oct. 2018 can be accessed online here.

For more of the latest 3D printing research updates sign up to the 3D Printing Industry newsletter, follow us on Twitter, and like us on Facebook. Seeking a career in engineering? Join 3D Printing Jobs now.

Featured image shows high purity scandium samples and a remelted scandium cube for comparison. Photo via Alchemist-hp/Wikimedia Commons