Scientists from Carnegie Mellon University (CMU) and Missouri University of Science and Technology have applied 3D printing to produce high capacity lithium-ion batteries.

Deemed “a major advance in 3D batteries” by the study’s authors, the findings have the potential to transform all portable electronic devices, from smartphones to laptops and games consoles.

3D printing a potential world first

Rahul Panat is an associate professor of mechanical engineering and lead author of the groundbreaking paper which is soon to be published in Additive Manufacturing journal. At 3D Printing Industry, we have been following Panat’s research for some time, through his term at Washington State University investigating 3D printed nanostructures, and on to his most recent appointment at CMU in 2017.

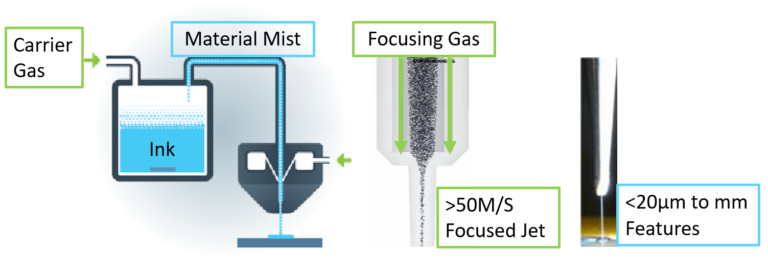

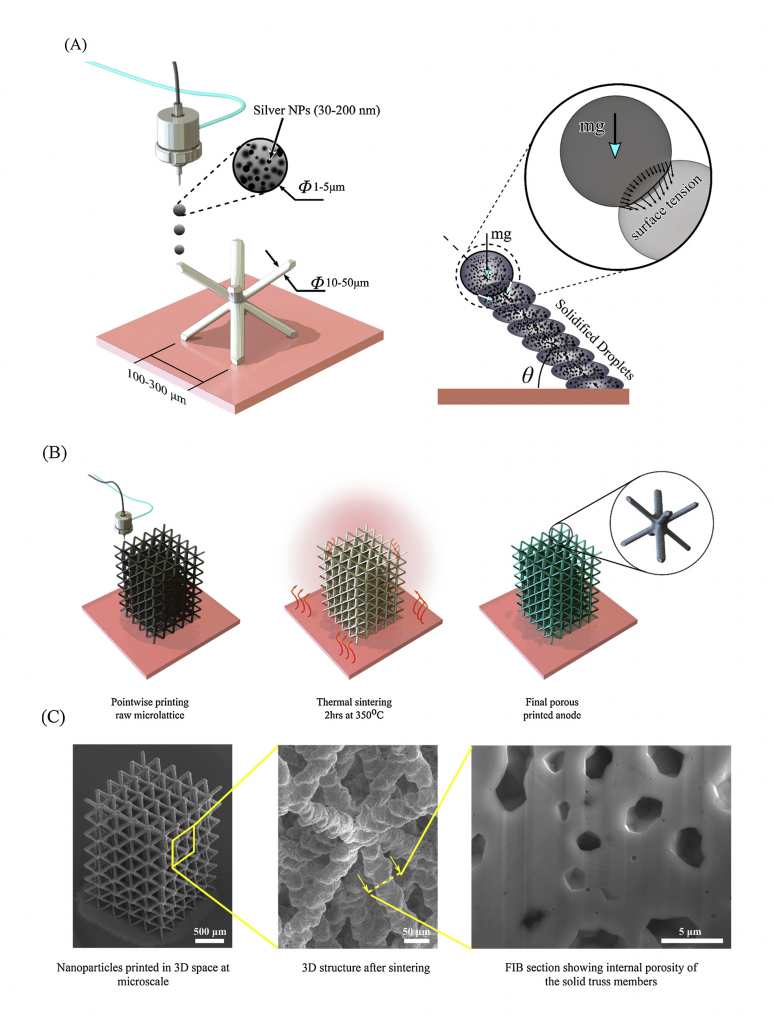

3D batteries are the most recent outcome of the CMU team’s work with Optomec Aerosol Jet Printing (AJP) technology.

In an interview with CMU news, Panat states:

“I don’t believe anybody until now has used 3D printing to create these kinds of complex structures.”

Increasing battery capacity

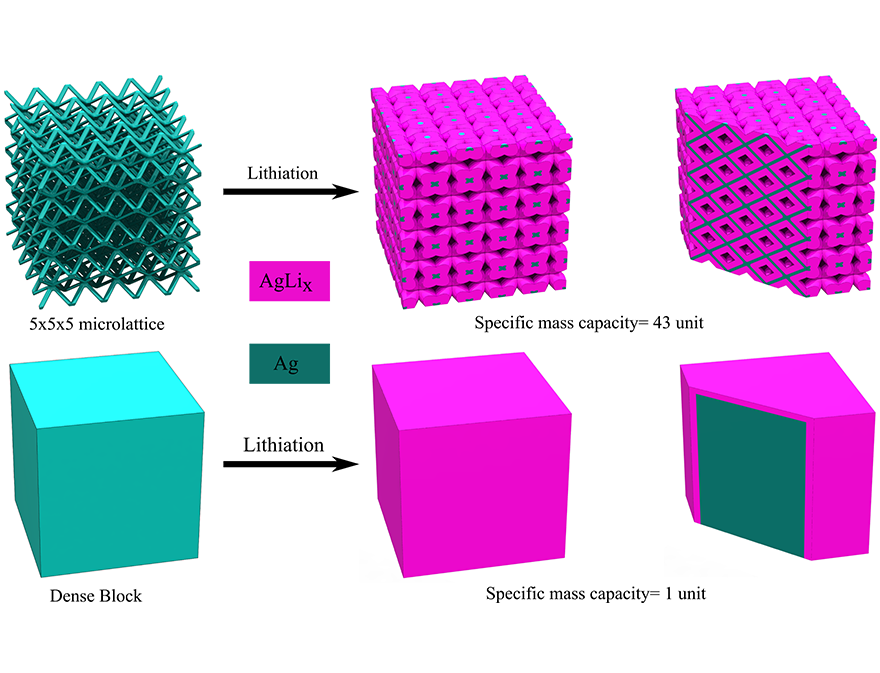

In this research, AJP has enabled researchers to create battery electrodes with a lattice geometry, increasing their porosity. By increasing the porosity of the cathode, much more volume (when compared to a solid battery block) can be utilized for energy storage, as Panat explains, “In the case of lithium-ion batteries, the electrodes with porous architectures can lead to higher charge capacities,”

“This is because such architectures allow the lithium to penetrate through the electrode volume leading to very high electrode utilization, and thereby higher energy storage capacity.”

The 3D printed electrodes are made from silver, and lithiated to incorporate the essential lithium content.

As a droplet-based deposition technology, AJP is one of the only means of creating such precise and complex geometries. Panat asserts, “If this was a single stream of material, [as in FDM/FFF technology] as in the case of extrusion printing, we wouldn’t be able to make them.”

3D printing batteries

When compared to a solid silver electrode, the 3D printed lattices showed an “unprecedented improvement in the battery performance” including a “400% increase in specific capacity” (in relation to the electrode’s weight) and a “100% increase in areal capacity” (relating to the charge retained over the area of the electrode).

Other projects applying 3D printing to the development of advanced energy storage include Harvard University’s award winning microbatteries, and an international study using graphene PLA to make anodes.

“3D printed hierarchically-porous microlattice electrode materials for exceptionally high specific capacity and areal capacity lithium ion batteries” is published online in Additive Manufacturing journal. It is co-authored by Mohammad Sadeq Saleh, Jie Li, Jonghyun Park and Rahul Panat.

To stay up to date with all the latest additive manufacturing research sign up to the 3D Printing Industry newsletter, follow us on Twitter, and like us on Facebook. Seeking a career in engineering? Join 3D Printing Jobs now.

Featured image shows SEM images of 3D printed Li-ion electrode lattice structures. Image via Rahul Panat and Mohammad Sadeq Saleh