A team of researchers at MIT CSAIL has collaborated with multi-material 3D printer developer Inkbit, to develop a novel computational methodology to improve the dense packing of objects.

Called “dense, interlocking-free and Scalable Spectral Packing” (SSP), this method offers significant potential for additive manufacturing. The research suggests that SSP can maximize 3D printing throughput, by batch 3D printing non-interlocking parts at high densities.

Lead researcher Wojciech Matusik argues that current batch 3D printing approaches “have very limited utilization of the [container] volume,” typically at a density of around 20%. “If we can increase the packing density we can increase the overall efficiency of the printing process, thus reducing the overall cost of manufactured parts.”

“The densities we’re getting, close to 40 percent, are significantly better than those obtained by traditional algorithms,” added Matusik.

SSP also offers value for a range of non additive applications, such as in warehouses and shipping, where various objects are regularly packed into boxes of different sizes.

This work represents “a breakthrough solution to a longstanding problem of effectively organizing 3D objects,” according to Bedrich Benes, a professor of computer science at Purdue University. “The proposed solution maximizes the packing density and has the potential to find applications in many practical areas, ranging from robotics to manufacturing.”

The research paper will be published in the journal ACM Transactions on Graphics next month. Additionally, the new technique will be presented at SIGGRAPH 2023, the world’s largest conference on computer graphics and interactive techniques, in August.

How does Spectral Packing work?

To develop this novel computational method, the researchers utilized voxelization. Here, both the container and objects to be packed were represented by a 3D grid composed of small cubes, or “voxels.” This grid highlights which voxels are filled, and which are vacant.

To determine an available space for each object, the SSP algorithm computes the collision metric at each voxel. This counts the number of occupied voxels that the object would overlap, or “collide” with. The object can then only be placed inside a voxel where no collision occurs.

Next, the best available position for the object must be determined. To achieve this, another metric is computed at each voxel, designed to locally maximize the packing density.

This metric measures the distance between the object and either the container wall, or another object in the container. The greater the distance, the higher the metric value. The goal here is to minimize gaps between objects, achievable by placing the object where the value is lowest. Matusik likens this to a game of Tetris, “You want to leave as little empty space as possible.”

Finally, the SSP algorithm must ensure that the package is “interlocking-free.” This is necessary to enable all objects to get to their assigned location, and also be separated from other objects when being removed.

This process requires a lot of calculations. Therefore, the team employed Fast Fourier Transform (FFT), a mathematical technique never before applied to the packing problem. FFT allows the task of minimizing voxel overlap, and minimizing gaps for voxels in the container, to be solved through a relatively small set of calculations. This negates the need to run tests on all possible locations for the objects to be positioned, drastically increasing packing speeds by several orders of magnitude

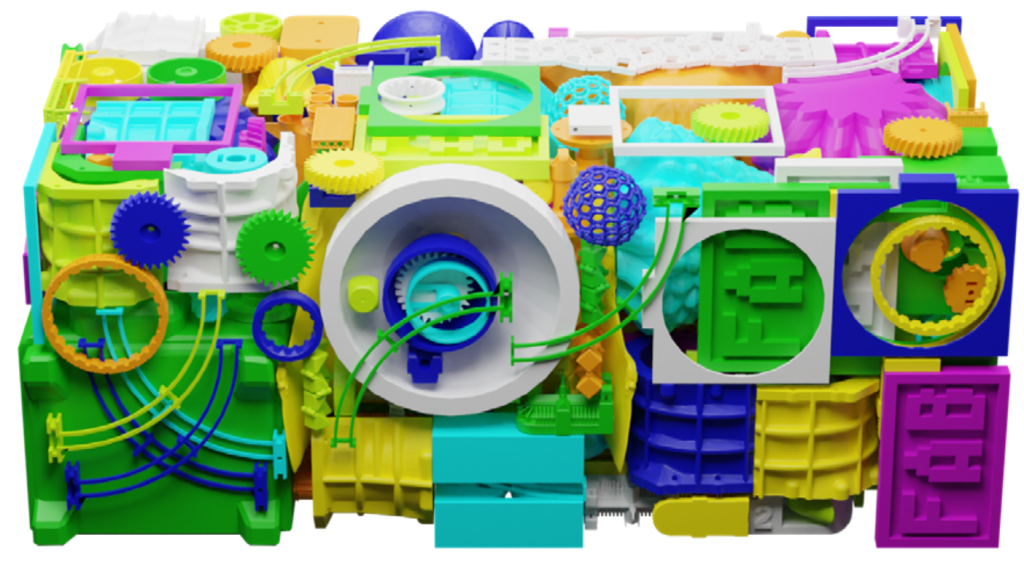

In fact, in one demonstration, this technique efficiently placed 670 objects in just 40 seconds, at a packing density of around 36%. Additionally, only two hours were needed to arrange 6596 objects at a packing density of 37.3%.

Batch production and scaling 3D printing

Batch production plays an important part in 3D printing mass production. Various companies are scaling up their additive capabilities to achieve mass production. Thus, there is certainly demand for optimizing production density to increase 3D printing throughput.

Last year, the venture capital arm of German chemicals firm Evonik invested in 3D printed pharmaceutical firm Laxxon Medical to accelerate the mass production of 3D printed tablets. This collaboration sees the mass production of novel multi-drug tablets using Laxxon’s patented 3D screen printing technology, and Evonik’s specialized polymer materials.

Elsewhere, SoonSer, the industrial brand of 3D printer and consumables manufacturer SoonSolid, launched its upgraded SLA 3D printer series, Mars Pro, to target the demands of industrial mass production. The Mars Pro series includes the Mars Pro 600, 850, and 1600 SLA 3D printers. These 3D printers are designed to offer industrial-scale manufacturing of SLA 3D printed parts with both speed and accuracy.

Subscribe to the 3D Printing Industry newsletter to ensure you keep up with the latest 3D printing news. You can also follow us on Twitter, like our Facebook page, and subscribe to the 3D Printing Industry Youtube channel to access more exclusive content.

Are you interested in working in the additive manufacturing industry? Visit 3D Printing Jobs to view a selection of available roles and kickstart your career.

Featured image shows 6596 objects packed into 26 trays. Image via MIT CSAIL.