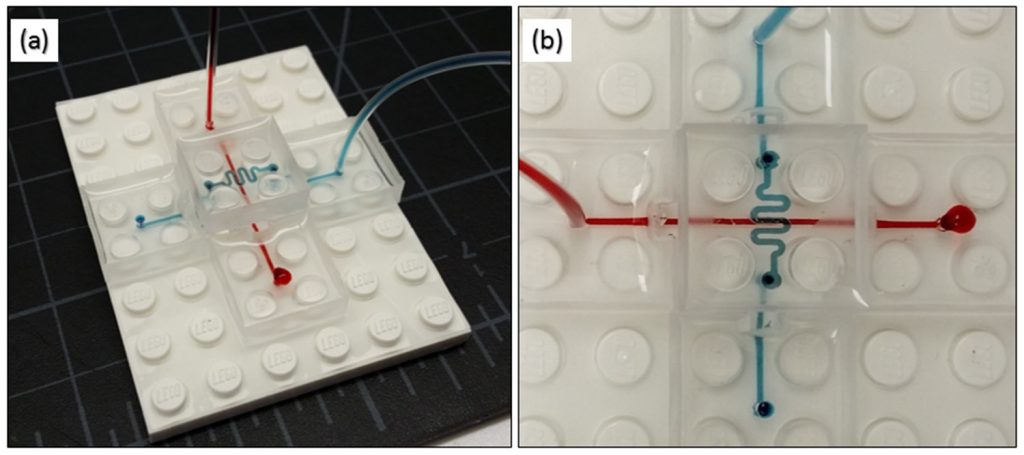

3D printed master molds have been used to create microfluidic LEGO bricks that facilitate the study of liquid flow for medical research. The LEGO brick method is being explored by the Department of Biomedical Engineering at the University of California, Irvine, with findings published in the Journal of Micromechanics and Microengineering, January 2017.

What is microfluidics?

Microfluidics is the manipulation and study of sub-microscopic litres of liquid. In a device such as the University of California’s LEGO bricks, liquids are channelled through empty vessels spanning no more than 500 μm (microns, for comparison: a human hair is 50 μm in diameter).

The way a liquid behaves during a flow, and when mixed with other nanoliquids tells researchers certain things about its biological behaviour, Microfludics can also be controlled in a way to produce autonomous movement, as in the example of Harvard University’s soft-robotic Octobot.

Moving .gif shows Harvard’s Octobot that harnesses microfluidic principles to move. Clip via: @NatureNews

In biomedical research microfluidic chips are used to conduct assays that test the reactions between substances, as in lab-on-a-chip technology. Using these devices is preferable to some traditional assay methods as the microscale parts consume less time and resources. California’s LEGO bricks seek to promote these qualities by providing more recognisable devices that are also capable of being mass produced.

Making the microfluidic LEGO bricks

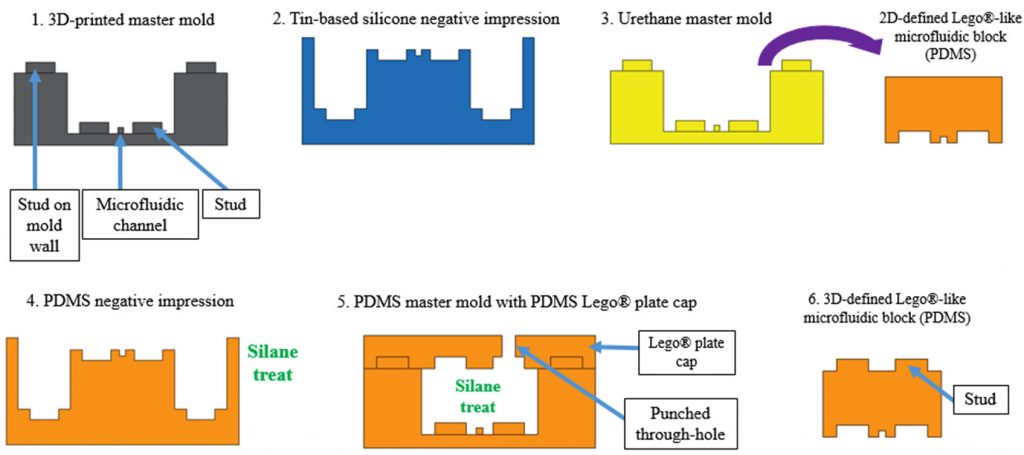

Kevin Vittayarukskul and Professor Abraham Lee’s approach uses Autodesk’s AutoCAD software to first design blocks with an embedded microfluidic channel.

From this a mold is also designed, and then 3D printed on a Perfactory 3 Mini 3D printer by EnvisionTEC that uses the DLP method of vat polymerisation to cure the material. PDMS, (Polydimethylsiloxane) a silicone-based polymer is then used to cast the LEGO bricks.

The properties of PDMS make it naturally transparent and biocompatible, which is ideal for this kind of research. It is also known for its ability to exactly match the shape of a cast into which it is poured, meaning that none of the DLP 3D printed quality is lost on the final cast.

A microfluidic LEGO kit?

The advantages of being able to stack the microfluidic blocks is that researchers can combine even more channels into a single space. It also allows easy assembly of varying channels, i.e. one straight vessel in to a winding one.

Using a tried and tested building block such as a LEGO brick also means that it has great potential for mass-production. The case with medical research is that it often isn’t accessible by other scholars that could make use of the technology. But a microfluidic LEGO kit could be just the ticket to encourage future biomedical research.

Speaking to EE Times Europe A truly LEGO®-like modular microfluidics platform co-author Professor Abraham Lee explains:

The main goal of this project was to train and educate the next generation of microfluidic developers and researchers. By using actual LEGO’s as the building block and assembly platform, our hope was to attract students as early as young as high schoolers to be interested in the field, learn about microfluidics and stimulate their imagination for new products for applications over a very wide range.

For more news direct from 3D Printing Industry, you can follow us on Twitter, like us on Facebook or sign up to our newsletter.

Featured image shows testing the flow of liquids through connecting LEGO bricks with colored inks. Image via: Kevin Vittayarukskul and Abraham Phillip Lee