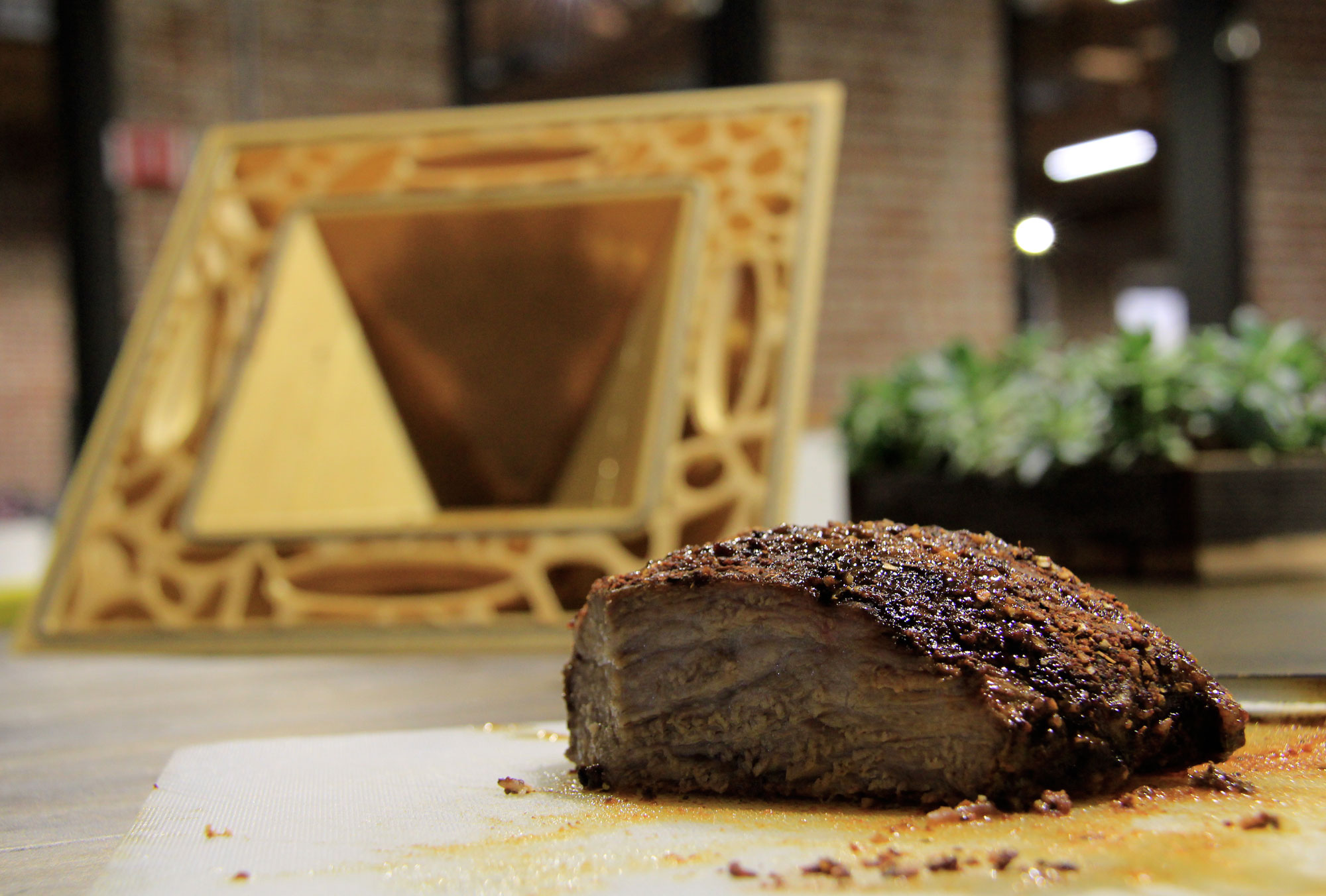

At first glance, the Pyra looks like a cross between a tiny ancient Egyptian tomb and an easy bake oven. Surprisingly this isn’t the tagline the scientists and engineers at Fathom are using. They explain their latest invention as a 3D printed smart oven that utilizes thermal heat to both bake your prized savories and sweets and to heat up new cell structures in a lab environment.

The team at Fathom studios uses their expertise in advanced additive manufacturing and 3D printing to help their customers with prototyping, design, and engineering of advanced technology. With the Pyra, the team has designed and engineered a truly innovative oven that will surely open up new roads in additive manufacturing.

Contrary to its name, the Pyra features no fire and only uses thermal heating. The oven also has no switches, buttons and no need to touch the device at all, after you’ve set the desired temperature with the web-based app and connected to the cloud. The Pyra functions primarily using a forced air convection and a 3D printed fan.

The Pyra is the brainchild of the director of research at Fathom, Carlo Quiñonez. Recently, Design Differently honored Quiñonez with their May ‘Model of the Month’ award for his work on the original design for the device, then called the Aquino Thermal Chamber. Quiñonez, who has a doctorate in biology, spent years developing the design for his prototype oven, originally conceived more as a lab tool that baked cell structures. In an interview with the Fusion 360 team on the Design Differently Blog, he said, “My big vision with this project is to enable community-driven development of the tools scientists use in the lab. The plan is to make the thermal chamber designs open-source so anyone can download, customize, and 3D print their own versions.”

Since 2009, when he originally began designing the oven, his vision has expanded to include Makers, bakers and lab technicians. Even at the origins of the project Quiñonez hoped that eventually, besides the necessary electronics, the oven could be entirely 3D printed.

Of course, there were a few challenges along the way, mostly in regards to the heat flow and geometry of the design. Another big issue was the need for plastics and materials that could hold up when exposed to the high temperatures.

Quiñonez needed to overcome the standard challenges of heating plastic without it melting. They had to make sure that the plastic was being evenly heated, that there were heat exchangers that were extracting some of the heat from the interior chamber, and that they were applying heat using low wattage per surface area. It also didn’t hurt that they found Stratasys’ ULTEM 1010 material, which is highly durable and has a NSF 51 food-contact certification.

The ingenious pyramid shape of the oven allows for the oven to achieve a uniform temperature up to 375 degrees. The shape also lends itself to additive manufacturing, as it allows for the use of self-supporting 45 degree angle sides. This gives the Pyra a clean, streamlined design without having to worry about adding or removing support structures after printing. The Fathom team under Quiñonez 3D printed the Pyra on the Fortus 900mc 3D printer and it took about 80 hours to complete the components for one oven.

The next step was Quiñonez’s open-source design employing Arduino and Raspberry Pi electronics. He hopes that others will find his design helpful and looks forward to any improvements the scientific and engineering community make to his original design. The design is certainly open to any specifications or modifications required for specific projects.

This is a classic example of the 3D printing process being only as good as what innovative minds bring to the technology. Quiñonez saw a specific need for communities of scientists to be able to design and create tools to fulfill their specific needs. In trying to meet one specific need, he ended up creating a very versatile device. From cupcakes to beef to cells, the Pyra has a bright future, as does Carlo Quiñonez and the innovators at Fathom.

Quiñonez says, “I hope this design inspires designers and engineers to challenge the way they think about product design and manufacturing. Every day, the FATHOM team is pushing the boundaries of what is possible for industry-leading companies across the country. Professionals need to rethink their approach because remarkable efficiencies can be achieved like never before.”