There are infinite possibilities to implement 3D printing in construction, architecture, and efficient housing. So many, in fact, that we have only begun to scratch the surface. So, although projects such as the 3D Printed Canal House in Amsterdam (or Winsun’s 3D Printed buildings in China, for that matter) remain extremely fascinating, there is a lot of research yet to be done in the field. That is what studio Lab3D, also based in the Dutch capital (of 3D printing) is doing with several different approaches.

The studio was founded by designers Hans Lankhaar and Bram van den Haspel, who are both very much focused on and fascinated by the possibilities of 3D printing. They start from the idea that “the world is on the verge of a new era of product design and product distribution.” Lab3d aims to contribute to this transition offering clever and feasible 3D designs and services that fit the context of the real world.

One of these is a 3D printed lightweight and very energy-efficient façade developed for DeltaSync, a company specialized in floating urbanization. In this case, high-resolution 3D printing made it possible to integrate all types of piping, window frames, and even thermal insulation in one material. The 3D printed wall has an outer and inner shell of 4 millimeters, with a honeycomb structure in between that not only gives the façade strength and stiffness, but also insulates, thus preventing loss of heat by convection, radiation, and transmission.

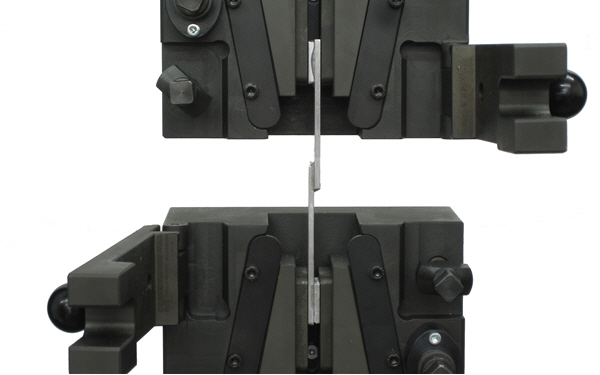

Another interesting recent project by Lab3d goes back to a concept which was first explained to me by Ronald Rael of Emerging Objects: the use of 3D printing to make smart-bricks or, in other words, modular housing components. Lab3D focuses on how to connect these 3D printed modules together. With the 3D Printed Internal Connector project, Lab3d developed a connection system for 3D printed elements. A plug and a counterpart with a spring system were 3D printed inside a single component, something which is clearly impossible to produce by conventional methods. The connector enables the assembly of smaller 3D printed elements into a larger whole.

Another way to achieve this goal is through adhesive. Together with Henkel, Lab3D tested different adhesives suitable for gluing together PLA, the most commonly used plastic in thermal-extrusion-based 3D printing. The adhesives were tested under extreme conditions in Henkel’s, along with the alternative approach of welding the PLA, which also showed promising results.

In much the same way, all the different projects focusing on the use of 3D printing in construction seem to represent many small bricks of the same larger project: smart, more sustainable, more affordable, and better housing. Lab3d could be working on a way to bind them all together as well.