Materialise, a global leader in 3D printing software and service solutions has announced the addition of seven technology partners in its CO-AM platform.

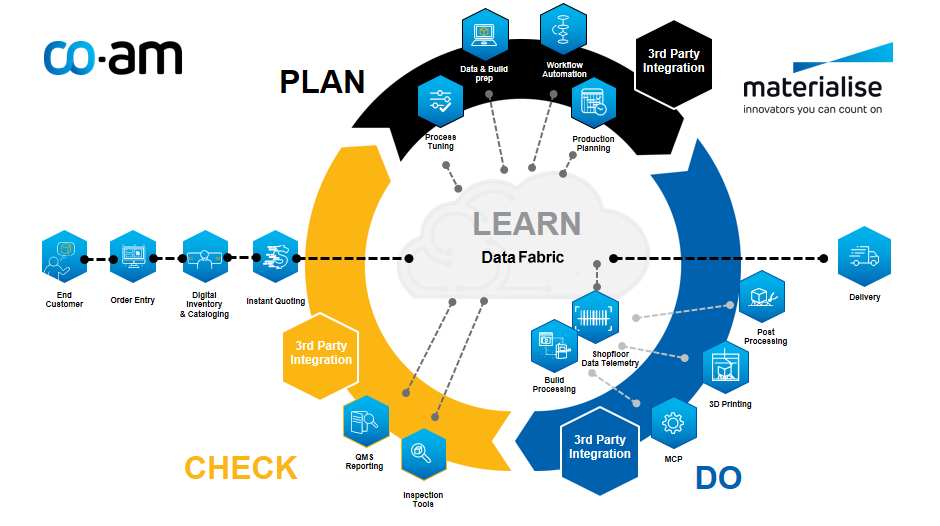

These solutions assist in the design and pre-printing automation, printing, post-processing, and traceability, for 3D printed parts. Additionally, Materialise Magics has been integrated into CO-AM offering a new workflow automation feature. Bart van der Schueren, CTO of Materialise said, “With these new partnerships, the CO-AM community continues to grow, creating the first end-to-end software platform that offers an open ecosystem for the additive manufacturing (AM) industry.”

“Collaboration is key to realizing the potential of additive manufacturing and to giving our customers seamless access to a full range of software tools to plan, manage and optimize every step of their 3D printing process,” added the CTO of Materialise.

CO-AM platform partners

The Materialise CO-AM platform provides the AM industry and manufacturing companies with room for advancements and co-development. It introduces an open software architecture that gives manufacturers immediate access to various hardware technologies in addition to their preferred tools from Materialise and other software developers. This will enable the CO-AM group to collaborate on end-to-end manufacturing solutions that will give individual companies a competitive advantage while also empowering entire industries.

Consumers in major manufacturing industries such as aerospace, automotive, consumer, medical, and energy will have access to the platform’s newest AM innovations and will be capable of seamlessly incorporating and connecting them.

Twikit aims to provide a mass customization solution that includes design automation and automated order creation, while Trinckle will be offering design automation for jigs and fixtures. Printer Connectivity with SLM Solutions‘ 3D printers facilitates digital traceability via automated labeling and authentication technology, whereas Additive Marking enables digital traceability via automated labeling and authentication technology. Solutions from AMT, DyeMansion, and PostProcess will be used for automating and tracking post-processing steps.

Manufacturing firms are increasingly using additive manufacturing to produce identical or customized products. They are, however, searching for ways to attain repetitive quality standards while minimizing the amount of human input. Materialise delivers on its commitment to link and optimize all stages of the AM process with the addition of seven new partners. Design, labeling, machine monitoring, and post-processing are all automated with the new solutions.

The CO-AM platform allows users to create a process that is distinctive to their company. They can select their preferred solution from a growing number of tools to support each step in the AM workflow.

“End-to-end connectivity in CO-AM offers significant advantages for our partners and our customers,” said Vishal Singh, Senior Director of CO-AM. “For our partners, connecting their applications to the CO-AM platform provides them with opportunities to reach new customers more efficiently. Our customers benefit from a unified user experience throughout Materialise and partner solutions.”

CO-AM Integration and Workflow Automation with Magics 26

Magics 26, Materialise’s flagship data and build preparation software, has also been integrated into CO-AM. The incorporation improves traceability by enabling users to track and enhance AM processes from data preparation to design iterations to the final printed part.

Furthermore, Magics’ new workflow automation feature provides off-the-shelf scripts for automating common build preparation workflows as well as the ability for consumers to utilize customizable scripts to automate build preparation tasks specific to their AM operations.

“The deep integration and workflow automation feature of Magics in CO-AM creates a digital thread between data and build preparation and the overall AM workflow,” said Egwin Bovyn, the product line manager of Magics 3D Print Suite at Materialise. “This is an important step to enable data management across all technologies within CO-AM. It will allow users to reduce production costs and scale AM operations more efficiently.”

Additive manufacturing platforms

This year, PostProcess Technologies, a developer of automated post-processing systems, and Enable Manufacturing, a metal 3D printing service, both launched 3D printing software platforms to take post-processing and additive manufacturing to new heights. PostProcess made available its CONNECT3D platform, a novel addition to its hardware, chemistry, and software stack that aims to fill lengthy gaps in the post-printing sector. Enable, on the other hand, had created a custom software package called EnableChain that is intended to automate and accelerate the delivery of metal parts manufactured using its Additive Casting technology.

Furthermore, Siemens Energy, an energy technology company entered a joint venture with metrology device manufacturer ZEISS to launch MakerVerse, a one-stop-shop on-demand 3D printing fulfillment platform. For projects that involve design prototypes and the production of spare parts on demand, the platform links industrial clients with a worldwide network of certified 3D printing suppliers.

3D Printing Industry interviewed the CEO of MakerVerse, and according to Markus Seibold, the platform fills a white spot in the market for industrial-grade additive manufacturing, with part quality at its very core. In this article, he shares his vision for the platform going forward and the role it will play in facilitating the greater adoption of industrial 3D printing.

“What sets us apart, I believe, is the fact that there is still not a fully established player in this market that can combine the advantages of a one-stop-shop digital platform with fully being able to support the needs and requirements of industrial-grade customers,” Seibold says.

Elsewhere, Dassault Systèmes, a software developer, launched Xometry, a marketplace for on-demand manufacturing, as the first “prime partner” in Dassault’s MAKE marketplace.

MAKE marketplace, which debuted in 2018, is a system that links designers with service bureaus and machine shops. At the time, Xometry was one of several early partners. Users can access additive manufacturing, CNC milling, and injection molding.

Follow this link for all the Formnext 2022 news.

To stay up to date with the latest 3D printing news, don’t forget to subscribe to the 3D Printing Industry newsletter or follow us on Twitter, or like our page on Facebook.

While you’re here, why not subscribe to our Youtube channel? Featuring discussion, debriefs, video shorts, and webinar replays.

Are you looking for a job in the additive manufacturing industry? Visit 3D Printing Jobs for a selection of roles in the industry.

Feature image shows Materialise CO-AM platform partners. Image via Materialise.