With at least 25 different 3D file formats currently in use around the world, MakePrintable is the cloud-based model fixing software that makes such files 3D printer ready. The software has auto-fix controls designed to eradicate all the stress caused by incompatible file formats.

In this article 3D Printing Industry get inside the software’s well-designed user interface, and takes MakePrintable for a spin.

Common fixes to 3D models. Clip via MakePrintable on YouTube

Red, amber, green traffic-light system

MakePrintable is provided by San Francisco-based 3D printing, gaming, and CAD company Mixed Dimensions. It is accessed via the cloud, and so can be used from almost any computer with an internet connection regardless of the operating system.

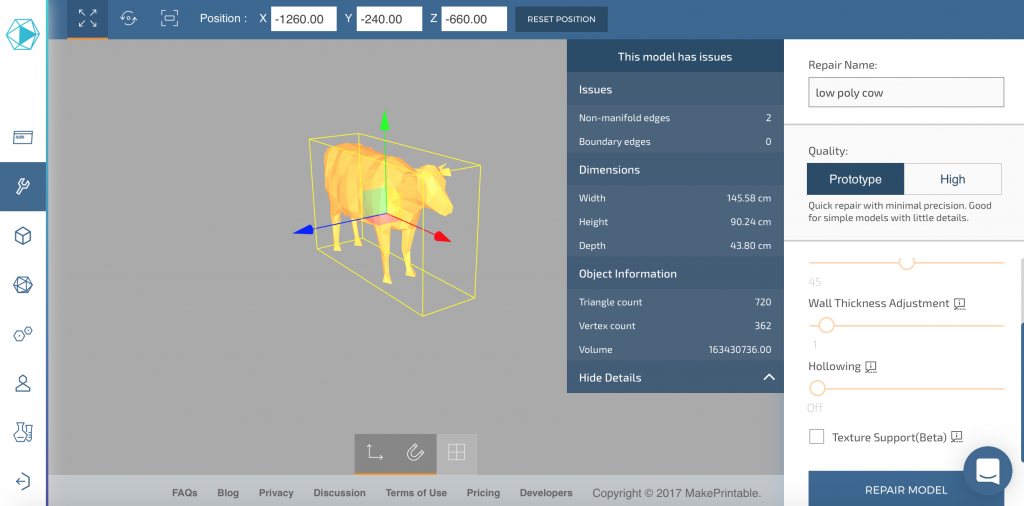

To test out the features, we uploaded a simple .obj file of a low-poly cow, designed for use in video games by tf3dm.com contributor snippysnappets.

Errors in the file are highlighted in yellow, the goal is to turn them green. The program generated report, “This model has issues”, counts the problems in a model’s internal and surface geometries.

You also get a warning if the 3D model is too small, an issue that is easily resolved by dragging the measurements bar at the top of the screen.

Simple and detailed models can be edited respectively in the Prototype and High quality modes on the right. Input and output polygon count, wall thickness, and object hollowing can all be adjusted using sliders.

Packing a punch with muti-processor power

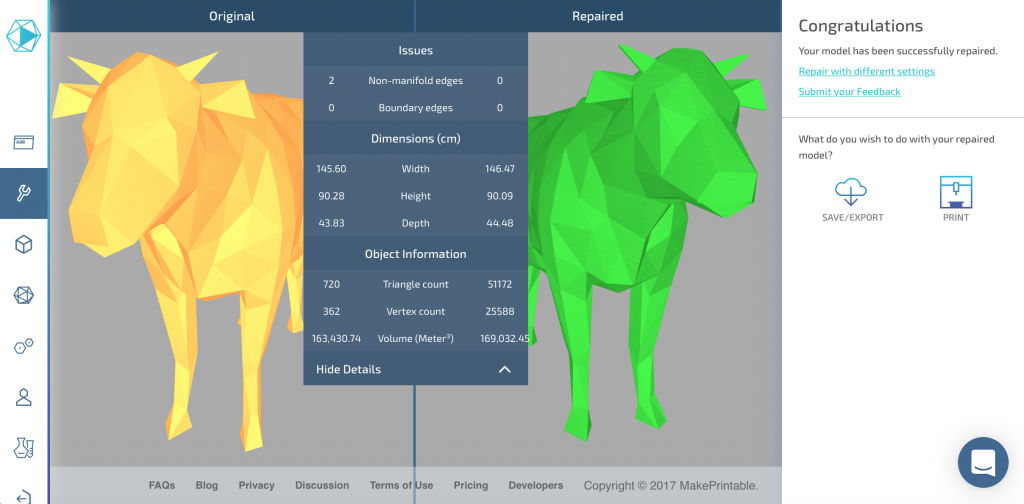

After custom changes have been made, its then just a case of clicking “Repair Model” and MakePrintable finishes the model to make it 3D printable. Unlike other fixing software that require download, MakePrintable processing is shared out over multiple GPUs to give more power and speed to the fixes.

Models can then be stored as a 3D model, a Scalable Vector Graphics file, or the G-code used to 3D print. Alternatively, it can be 3D printed directly from the software.

Try MakePrintable for free

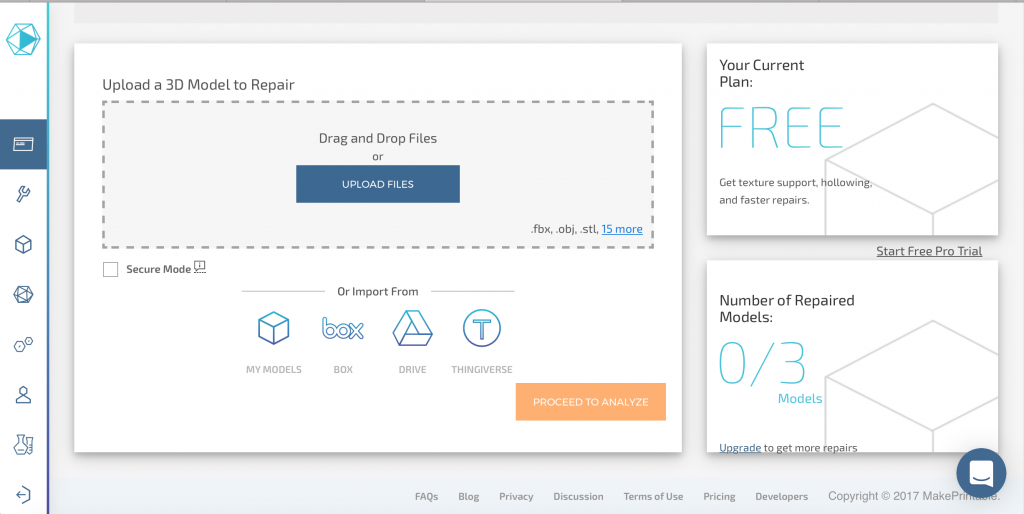

The free trial version allows users to repair 3 models per month. If users have a higher output, Pro subscriptions at $7 per month allows up to 7 models, and the $25 Plus subscriptions give up to 50.

During earlier testing stages of MakePrintable, 3D Printing Industry spoke to Mixed Dimensions founder and CEO CEO Muhannad “Mo” Taslaq. In the interview, Taslaq shares more of the company’s vision for a user-friendly fixing program.

The rigorous testing is now complete and MakePrintable is ready ready to take the next step. The company is currently work on its Mammoth project which is, “optimizing our repair technology in order to handle really complex files and large files within a short time window (30 sec- 2 mins).”

Try MakePrintable for free by following this link and let us know your experience in the comments below.

For our review of the Mammoth update when it comes out, sign up to the 3D Printing Industry newsletter and follow our active social media channels.

Featured image shows a robot dog model and mesh. Image via MakePrintable