Sheffield, UK, based MachineWorks has released a new hole filling tool as part of their Polygonica mesh editing software for 3D models.

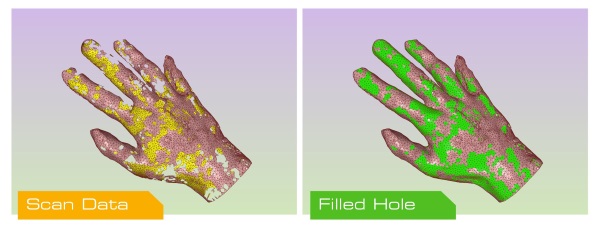

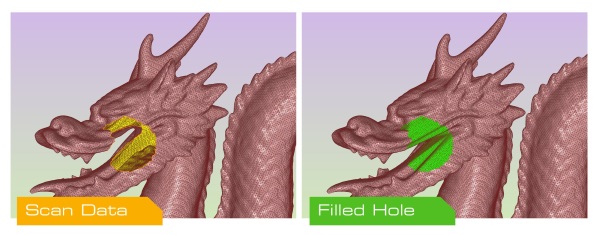

Sometimes the shape of an object prevents the easy 3D scanning of its entire surface. In these cases the resultant 3D model will have holes. Filling these holes is an often time consuming process and when automated can yield imperfect results, smoothing over details that existed in the physical object, and producing an inaccurate 3D model.

Polygonica’s new hole filling algorithms use data in the original geometry of a scan, and should hopefully reduce the time needed to prepare a scan for 3D printing.

Advanced mesh repair features

Multithreaded code has been implemented, granting performance improvements on multicore processors. New algorithms use existing scan data to improve the filling of large holes. Both improve the speed of hole filling.

Holes containing mesh fragments, “annular holes”, will be filled more effectively by algorithms matching features of the fragments to the hole. A new fill type applies features on one side of a hole and extends them across the hole. Polygonica say this is often more effective, and maintains more detail than simply finding a minimum area or smooth fill for the hole.

The advanced hole filling features together with Polygonica’s existing repair functions will help ensure models are watertight, free of badly oriented planes, self-intersections, and closer to being ready for 3D printing.

Automated processing of 3D models

Polygonica’s automated processing of 3D models is a key feature of Stratasys’ GrabCAD Print software. Dr Fenqiang Lin, MachineWorks Managing Director, said “GrabCAD and Polygonica share the same philosophy of enabling a single ‘click-to-print’ methodology for 3D models. The user doesn’t want or need to know about what software is used to prepare the file, they just want their CAD model printed with the minimum of fuss.”

Less extensive automated hole filling options are also available with software like Artec Studio. Peel 3D’s $6,000 handheld 3D scanner uses proprietary software to automate hole filling and the smoothing of edges.

For more information about Polygonica’s capabilities and applications, you can read the 3D Printing Industry article about our visit to Polygonica.

Keep up to date with the latest 3D printing news. Subscribe to the 3D Printing Industry newsletter, follow us on Twitter and like us on Facebook.

Vote for the software the year in the 2018 3D Printing Industry Awards.

Our 3D Printing Jobs service is now live. Post a job or advance your career in 3D printing now.

Protolabs is sponsoring the 2018 3D Printing Industry Awards design competition. Enter now for the chance to win a Wanhao Duplicator 9 3D printer.

Featured image shows Larger holes processed, whilst keeping detail with Polygonica. Image via Polygonica.