While the name Polygonica may be unfamiliar, chances are if you work in the 3D printing industry you have used their product. From an office in the historic manufacturing city of Sheffield, UK, MachineWorks software has been a driving force powering the machining industry since 1994. As manufacturing moves into the digital era MachineWorks seized the opportunity to adapt their expertise to 3D printing. 3D Printing Industry visited the company to learn more about Polygonica.

3D mesh simplification of a Stanford bunny graphics test. Clip via: Polygonica Software on YouTube

Healing the bane of 3D printing

Cristina Sesma, head of marketing for MachineWorks tells me that Polygonica was born out of a singular idea that we can all relate to: technology is great, but only when it works.

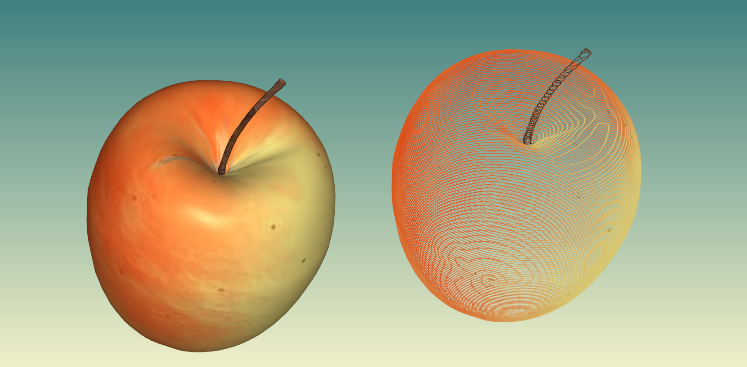

Polygonica provides its users with the toolkit necessary to successfully produce a polished object, ironing out any holes and conflicts found in 3D object files. The processing software is mesh based, and works using mathematical Boolean principles.

The Boolean engine is key to all of Polygonica’s possibilities. It is used to offset 3D models, for mesh healing & analysis, point cloud processing, and remeshing to simplify a model’s structure.

No ‘one-size-fits-all’

Polygonica is not an end-user package. Instead it provides a code capable of being tailored to any machining need. As Sesma explains to me on my visit, this means that MachineWorks remain close to their clients throughout their design lifecycle.

Renishaw (LON: RSW), also based in the UK, are one of Polygonica’s clients. Founded in 1973, the company engineer solutions for aerospace, power and healthcare industries. Particularly prominent is Renishaw’s development of metal 3D printing from powder based materials. As 3D Printing Industry editor Michael Petch found out when he spoke with Renishaw’s director of Global Solutions Centers, Marc Saunders, Design for Additive Manufacturing (DfAM) is an under-exploited opportunity.

Polygonica in dentistry

Renishaw’s software engineering manager David Turner highlights how the company use Polygonica in for the dentistry market segment.

Speaking at Tech Soft 3D’s HOOPS Summit, Turner explains, ‘mesh integrity is absolutely key to us’, showing a digital 3D model of teeth with a hole in it that can be 3D printed. This hole creates structural weakness within the model, meaning that there is potential for it to break.

Integrating Polygonica into their proprietary software is how Renishaw eliminate these issues.

The toolkit is also implemented in Stratasys’ GrabCAD Print software. Consolidation of the two frameworks making for a more powerful CAD tool for 3D printing.

The success is in the toolkit’s versatility – it can be adapted to fit any new task. And that’s why Sesma says they will never be interested in make an end-user software package.

Taking 3D printing for granted

Polygonica believe that 3D printer users should be able to ‘simply print’ from their hardware, the same as 2D paper-printers are now taken for granted. Failed 3D prints are the stuff 3D Printing Industry’s nightmares are made of, so we certainly can’t argue with that.

If any of our readers would like to take a closer look at Polygonica for themselves, they will be at Formnext, AMUG, TCT and Rapid conferences in 2017.

Polygonica can also be nominated for the 3D Printing Industry Awards at this page.

Featured image shows a 3D printed Standford bunny graphics test. Photo via: Makerbot