Researchers from the Royal Danish Academy of Fine Arts Schools of Architecture, Design and Conservation (KADK) and the Danish Technological Institute (DTI) have developed a new approach to 3D printing in construction.

Introduced as the Sparse Concrete Reinforcement In Meshworks (SCRIM) concept, researchers have combined robot-based concrete 3D printing and textile reinforcement meshes to produce lightweight structures. This method enables “full exploitation of 6-axis robotic control by utilizing supportive meshes to define 3D surfaces onto which concrete is selectively deposited at various orientation angles.”

Eco-friendly concrete 3D printing

According to the researchers, concrete is the most commonly used material in the construction industry, with it low-cost and easy deployment creating an expected increase in the coming years. With such high global consumption, concrete has become a primary contributor to CO2 production. To reduce the negative effects of making this material, KADK researchers sought out digital fabrication methods which could lead to new design and construction practices.

New technologies such as 3D printing have enabled the rapid construction of a 500-square-foot concrete barrack for the U.S. Marine Corps Systems Command (MCSC), a drone R&D laboratory for the Dubai Electricity and Water Authority (DEWA), as well as creation of the U.S’ largest 3D printed concrete building known as the B-Hut – which intends to be used as refugee housing.

Nevertheless, the team recognized that techniques such as concrete 3D printing have limitations. This is due to its approach which stacks materials vertically, which is said to restrict “build orientation and incorporation of reinforcement.” Thus, the SCRIM method was created.

“Conventional [concrete 3D printing] approaches generally have challenges with the incorporation of reinforcement and other architectural elements,” said Wilson Ricardo Leal da Silva, a Product Manager at the DTI. “In contrast to the stacking approach, the SCRIM concept employs carbon-fiber-reinforced polymer meshes that are printed upon directly.”

The SCRIM concept

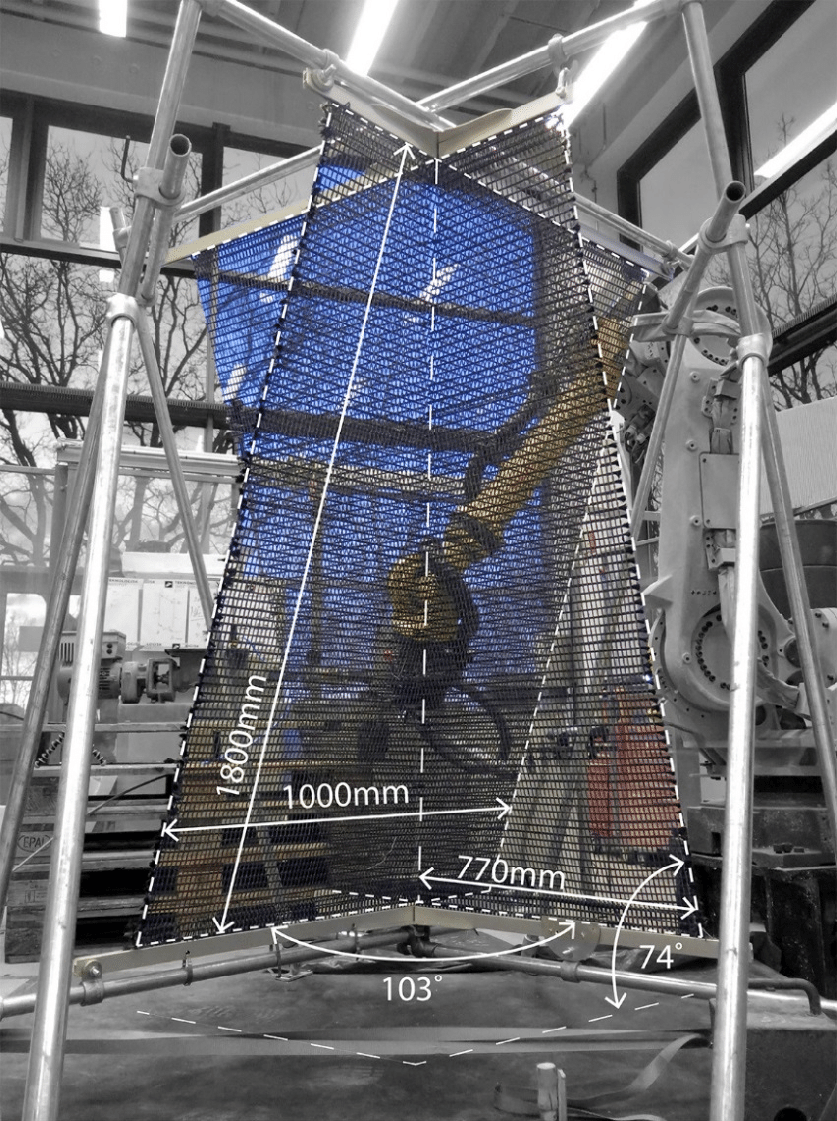

The SCRIM concept applies carbon-fiber reinforced polymer meshes into 3D target geometries. Concrete is then selectively deposited into the mesh to achieve a specific structure, enabling a reinforcement element as well as a stay-in-place formwork.

“The SCRIM method contributes to diversifying the existing spectrum of digital construction approaches in a field that is being heavily explored in the research community. A key difference is that SCRIM fully engages the 3D control and movement capabilities of six-axis robotics,” said Phil Ayres Teaching Associate Professor and Researcher at KADK.

“From a design perspective, this opens new creative potentials. [It] enables off-site printing and component-based assembly. In addition, because concrete is selectively deposited, this helps reduce concrete consumption and enable the production of lighter building components.”

To further develop their method, the researchers are planning to refine the concrete mix design and its related properties. In addition, they hope to develop a tailored carbon fiber reinforced polymer mesh for adaptive robotic control. The researchers are also seeking industry partners to develop the concept towards the production of building components.

A full paper on this research can be read online as “SCRIM – Sparse Concrete Reinforcement in Meshworks.” It is co-authored by Phil Ayres, Wilson Ricardo Leal da Silva, Paul Nicholas, and Johannes Portielje Rauff Greisen.

Keep up with the latest 3D printing news by subscribing to the 3D Printing Industry newsletter. Also, follow us on Twitter, and like us on Facebook.

Searching for new talent or seeking a career change? Search and post 3D Printing Jobs for opportunities and new talent across engineering, marketing, sales and more.

Featured image shows the SCRIM method in its first and second attempt. Image via KADK/DTI.