The Additive Manufacturing Team at Marine Corps Systems Command (MCSC) has 3D printed a concrete barrack in 40 hours. The 500-square-foot barrack was built at the U.S. Army Engineer Research and Development Center in Champaign, Illinois.

The barrack will serve as a test for further military use of concrete for 3D printing construction.

“In active or simulated combat environments, we don’t want Marines out there swinging hammers and holding plywood up,” said Captain Matthew Friedell, project officer in MCSC’s Operations. “Having a concrete printer that can make buildings on demand is a huge advantage for Marines operating down range.”

The Marine’s concerte 3D printed construction

This new barrack acts as an improvement on the U.S. Army Corps of Engineers’ previous 3D printed cement barrack. The previous barrack, known as B-Hut, was created by Automated Construction of Expeditionary Structures (ACES) and marked the military’s first foray into concrete 3D printing.

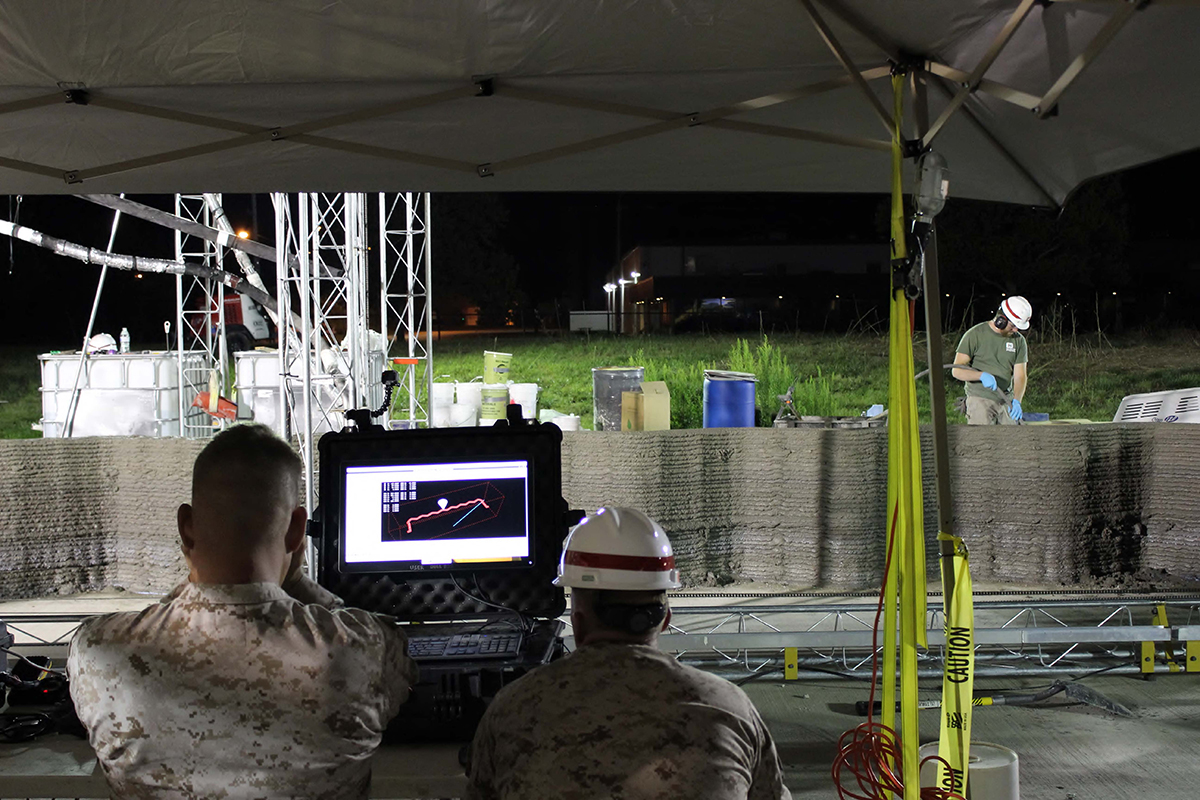

The new barrack was designed using a CAD file stored on a military hardened laptop, which sent the design to the 3D printer. The 3D printer then used a sliding metal gantry, mounted with a print head and mixer pump, to print the barrack by continuously layering concrete onto a flat stone base.

The barrack was printed with the U.S. Army’s expeditionary concrete composite, as a joint effort between the two branches.

By using 3D printing for construction, the military hope to be able to build stronger barracks at a faster rate. According to the Marines, constructing a wood barrack would require 10 Marines and 5 days, but with concrete 3D printing, a sturdier barrack can be built with 4 marines in 40 hours.

While the U.S. armed forces have 3D printed large structures in the past, they are often not done onsite or all at once. According to Captain Friedell, this barrack is the military’s first onsite continuous concrete print. It could potentially allow for faster construction in more remote areas.

The Captain later added that though the Navy and Marine Corps are the first military services on site in natural disasters, they have always struggled to provide proper shelter in a timely manner. With 3D printing construction, the military can quickly provide sturdy replacements for homes, schools, and community buildings.

The Marine research team hopes the concrete 3D printing technology will be used in a full range of military operations, from combat environments to humanitarian aid.

“This capability would enable a great partnership with the local community because it is low cost, easy to use, and robotics could print the buildings,” Friedell said. “We can bring forward better structures, houses and forward operating bases with less manpower and fewer Marines in harm’s way.”

Improvements in 3D printing for construction

Other organizations have also begun taking advantage of 3D printed construction. Last year, MIT’s Mediated Matter lab used expanding foam and concrete to 3D print a dome shaped building in under 14 hours.

Similarly, the Institute for Advanced Architecture of Catalonia (IAAC) have used clay 3D printing for eco-friendly construction. Earlier this year, Valencia based company Be More 3D, used cement 3D printing to create an entire home in 12 hours.

Recently, in France, the Ramdani family became the first family to ever move into a 3D printed home.

Want to stay up to date on 3D printing news like this? Then sign up to our 3D Printing Industry newsletter. Alternatively, you can follow us on Twitter, and like us on Facebook.

Looking to join an innovative additive manufacturing firm? Search open opportunities and apply with 3D Printing Jobs.

Featured image shows the concrete barrack being constructed. Photo via Marine Corps.