The Institute for Advanced Architecture of Catalonia (IAAC) based in Barcelona, Spain, is developing methods for large scale 3D printing that use unfired clay and robots to make eco-friendly architectures.

The methods, once matured, could transform the way houses and other structures are designed and built to make the most of a material’s natural properties, and fit within time, location and resource restraints.

Going “beyond the robot”

The institute’s Pylos technology objective is to go “beyond the robot” and allow “design research based exclusively on the material properties and behaviour” rather than just mechanical movements. Two projects from the institute, Terra Performa and On Site Robotics, tackle this initiative from different angles, taking a modular approach in the first instance, and a fully high-tech integration in the second.

Reinstating the structural endurance of clay

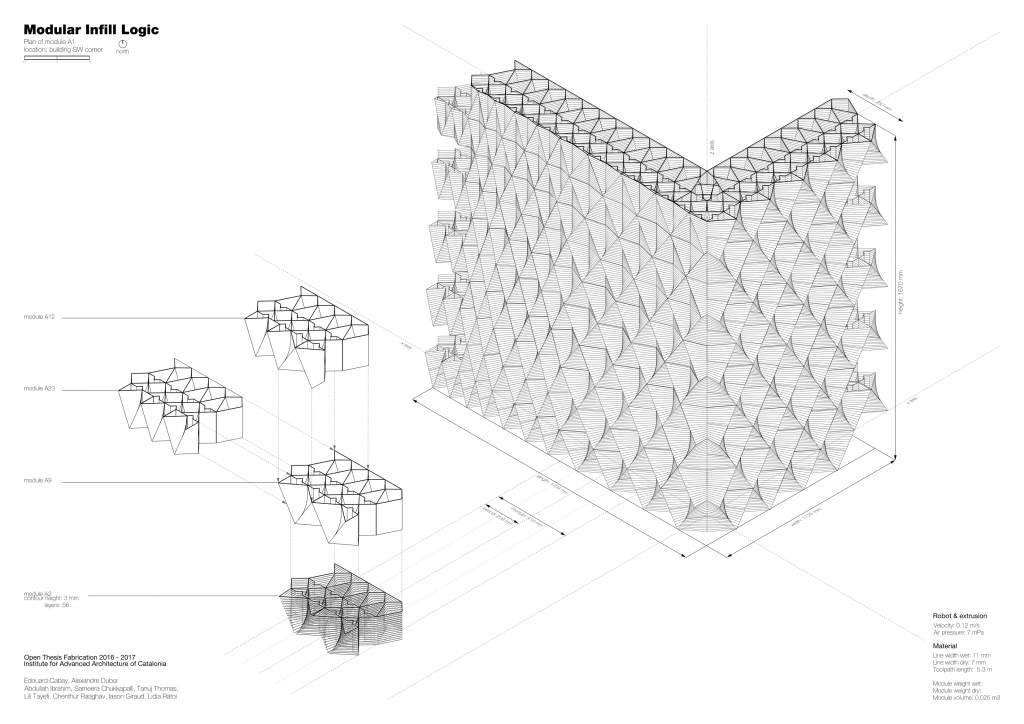

In Terra Performa the IAAC return to traditional clay based material for its ability to self regulate the humidity and climate of a construct. By applying the clay using a robotic arm and parametric, cutting-edge design, the Terra Performa project hopes to undo the stigma attached to clay’s association with only “traditional” or “underdeveloped” areas.

To make the idea transportable, the IAAC takes a modular approach to the design, 3D printing the clay in a series of wave like “bricks” that naturally fit together.

Drone monitored and flexible construction

On Site Robotics is a collaboration between the IAAC and Spain’s Tecnalia materials engineering company. In the project a Cogiro cable robot is installed with an extruder and suspended above a build area by a specially designed frame. In effect, the Cogiro is like a scaled up FDM 3D printer, but moves on wires suspended on a frame rather than the frame itself. A similar principal to Torbjørn Ludvigsen’s Hangprinter.

The main advantages of such a set up is that it has six degrees of freedom and can easily be installed on any level foundation with a size determined only by the height of the winches. Additionally, the cost of production is not dependent on the size of the space.

The Cogiro is optimized to 3D print in the IAAC’s 100% natural clay-based material. It also works alongside flying drones programmed to monitor the build, and record thermal information of the clay as it dries to avoid any unstable layers.

Taking the initiative

Other projects looking into 3D printing for construction include Russia’s Apis Cor that 3D printed a house in 24 hours, and Chinese company Winsun that is leasing 100 of its 3D printers to a Saudi Arabian construction contractor.

Poland’s Association of Innovative Technologies (Stowarzyszenie Innowacyjnych Technologii) has also developed a machine for 3D printing façades. SKRIBI is able to make monochrome images in plaster by employing the sgraffito technique of removing upper layers of a surface and create contrast with the lower, typically lighter, layers of a material. The machine is under development to be able to create multicolored reliefs that can be used for decoration panels for buildings.

Spain’s IAAC is also behind the 3D printed bridge installed just outside of Madrid, and home to the Fab City movement seeking to localize production whilst simultaneously connecting with nations around the world.

To stay up to date with the latest news for 3D printing in architecture, sign up to the 3D Printing Industry newsletter and follow our active social media channels.

Featured image shows a modular Terra Performa structure made from 3D printed “bricks”. Photo by the Institute for Advanced Architecture of Catalonia. All images featured in this article are courtesy of IAAC.