Torbjørn Ludvigsen is a RepRap enthusiast, and has a Master’s degree in engineering physics from Umeå University in Sweden. From the last week of February 2017 to 9th March 2017 he has been 3D printing a gigantic Tower of Babel using his invention: the Hangprinter.

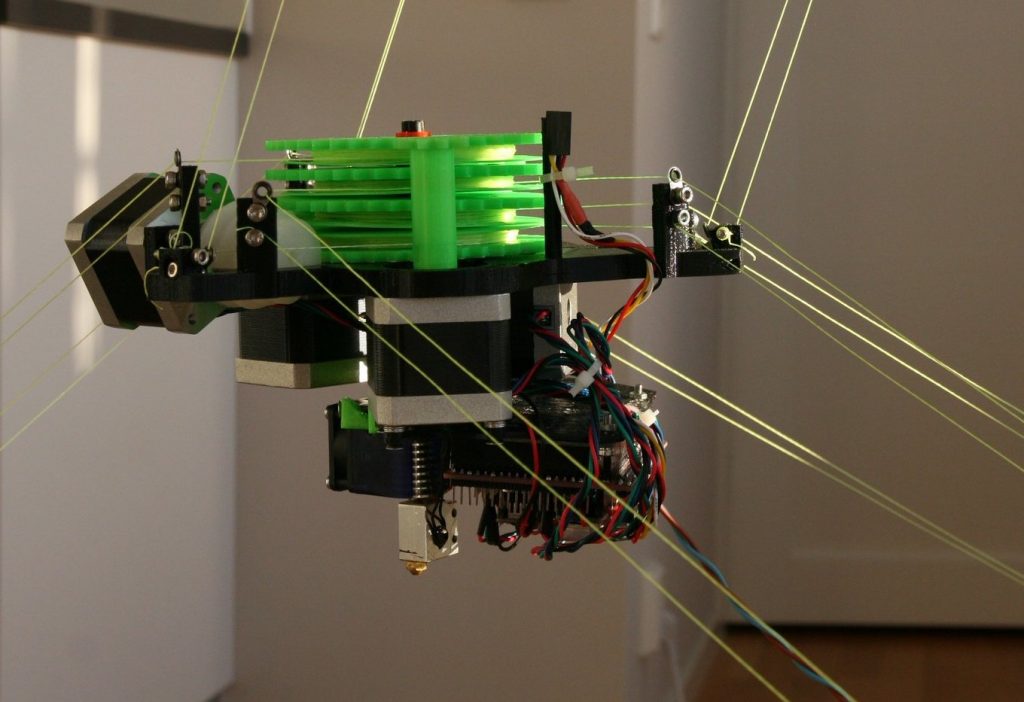

The Hangprinter in action. Clip via Torbjörn Ludvigsen on YouTube

The Hangprinter is designed to make large-scale free form 3D printing available to anyone. In this interview, 3D Printing Industry speak with Torbjørn, also known as tobbelobb on Twitter, to learn more about the project, and keeping things open source.

“can’t we just suspend the print head from the ceiling and be done with it?”

The project got started with Torbjørn taking the RepRap project slogan, “make one for a friend”, quite literally. He says,

While showing a friend how to properly align a RepRap 3d-printer frame he got frustrated and said “can’t we just suspend the print head from the ceiling and be done with it?”

I thought about the idea for a while and realized it’s a very sensible idea. You dodge all the limitations of frames (cost, build time, build volume) by utilizing existing structures instead.

Since the first machine, Torbjørn has launched Patreon-like campaign to give the Maker community his support in setting up their own Hangprinters, and the opportunity to support “a faster, lighter and more user friendly successor to the machine”.

The Tower of Babel

The completed Hangprinter Tower of Babel is 4.5m tall, and uses a 30-40% wood dust blended PLA. It was 3D printed by Torbjørn at Sliperiet in Umeå University.

Sliperiet is the university’s platform to encourage cross-discipline collaboration of artists, researchers, businesses and students, and encompasses a FabLab. The Sliperiet initiative has also launched the +Project, challenging collaborated to 3D print a wooden house over the course of three years.

“Breeding” in the RepRap community

A large portion of the Hangprinter parts are all 3D printable, and Torbjørn shares the designs freely. However, if backer interest dictates it, he will look to producing a whole kit for purchase.

He adds,

Like Adrian Bowyer I envision a (continued) development of “breeding”, where 3d-printers are used to manufacture improved or more specialized 3d-printers.

[…]

Lubricating this “breeding” process will help people customize the technology for their own specific needs.I think companies will discover the value of the RepRap project and start constructing more custom machines, rather than continue to buy boxed and expensive Ultimakers and Makerbots in the future.

3D Printing Industry recently reported on the RepRap community’s response to Ultimaker’s “defensive” patent application. The project’s founder, Adrian Bowyer, is also to be recognised for his outstanding contribution to the industry in the first annual 3D Printing Industry Awards.

To stay up to date on movement in the open source RepRap community, sign up to the 3D Printing Industry newsletter, and follow our active social media channels.

Let us know your thoughts on the frameless Hangprinter in the comments below.

Featured image All images featured in this article are from Torbjørn Ludvigsen on Twitter.