Researchers at Carnegie Mellon University’s (CMU) Human-Computer Interaction Institute (HCII) and Morphing Matter Lab have developed a method for adding new dimensions to one of the oldest materials on Earth – paper.

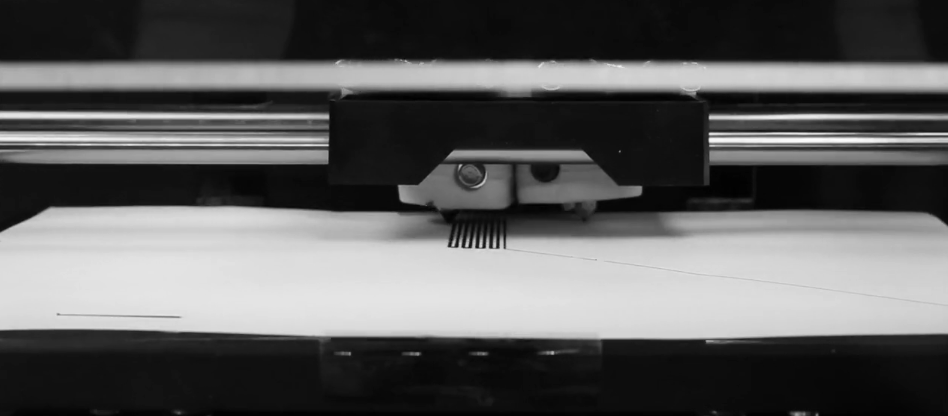

Using a FDM 3D printer, the researchers have turned cheap sheets of copy paper into reversible actuators that bend, fold or flatten when an electrical current is applied.

“Most robots — even those that are made of paper — require an external motor,” said Guanyun Wang, a Postdoctoral Fellow in the HCII. “Ours do not, which creates new opportunities, not just for robotics, but for interactive art, entertainment and home applications.”

Thermorph from Morphing Matter Lab on Vimeo.

Origami robots

With basic actuator designs, the researchers created self-forming paper structures to create balls and cylinders. With success the team integrated origami forms, such as kirigami, to enable more elaborate and functional paper structures that form into lamp shades, plants, and pop-up art.

“We are reinventing this really old material,” said Lining Yao, an Assistant Professor in the HCII and Director of the Morphing Matter Lab.”Actuation truly turns paper into another medium, one that has both artistic and practical uses.”

This method was used earlier this year by 53 students from Zhejiang University in Hangzhou, China, who created elaborate pop-up books using design interpretations of famous artworks, such as Van Gogh’s Starry Night and Sunflowers.

Paper actuation technology

According to Tingyu Cheng, Research Associate in Morphing Matter Lab, creating a paper actuator is a relatively simple and cost-effective process. It begins with an inexpensive FDM 3D printer which is used to lay down continuous “off-the-shelf” filament of melted thermoplastic, i.e., graphene polylactide composite — which conducts electricity.

Printed using a single layer onto plain copy paper, the thermoplastic actuator is just half a millimeter thick. Following this process, the actuator is heated in an oven or with a heat gun; the paper is then bent or folded into the desired shape and left to cool. This form remains as the default shape of the paper.

Electrical leads can then be used as a power supply to heat the actuator which causes the thermoplastic to expand and straighten the paper. Upon removing the electrical current, the paper returns to its default shape. In addition, the researchers have also developed techniques for printing touch sensors, finger sliding sensors and bending angle detectors that can control the paper actuators.

New dimensions with 3D printing

The shape-shifting abilities of additively manufactured polymer composites have also contributed to new dimensions within 3D printed objects. When these materials are met with environmental changes, for example, heat, moisture, or stress, the structure of the 3D printed object is also changes and can revert back to its 2D structure.

This concept has created a self-folding tulip from TU Delft researchers demonstrating the potential for morphing medical implants and has exhibited potential for aerospace grade components with ceramic-polymer composites shapeshifting structures.

Currently, CMU researchers are planning to refine the 3D printed actuator method by changing the printing speed and the width of the line of thermoplastic to achieve different folding or bending effects. Furthermore, the researchers intend to experiment with materials that are more heat conductive (plastics and fabrics) as well as develop particular filaments for use in actuators.

The printed paper actuator will be exhibited at the Ars Electronica Festival in Linz, Austria and BOZAR Centre for the Fine Arts in Brussels, Belgium next month.

The research paper “Printed Paper Actuator: A Low-cost Reversible Actuation and Sensing Method for Shape Changing Interfaces,” published on the ACM Digital Library is co-authored by Guanyun Wang, Tingyu Cheng, Youngwook Do, Humphrey Yang, Ye Tao, Jianzhe Gu, Byoungkwon An, and Lining Yao.

Keep up with the latest news 3D printing sign up to the 3D Printing Industry newsletter, Also, follow us on Twitter, and like us on Facebook.

Are you searching for new talent or seeking a career change? Search and post 3D Printing Jobs for opportunities and new talent across engineering, marketing, sales and more.

Featured image shows a paper robot operating from 3D printed actuators. Clip via Morphing Matter Lab.