One of the major barriers to widespread adoption of 3D printing is the question of standardization. For industries like aerospace and medical especially, there is a need for technical standards to maintain the safety and repeatability of printed parts, as well as the integrity of anything made with additive manufacturing.

In the wider world beyond 3D printing, several organizations exist to promote such technical standards and to enhance product safety, reliability and quality. The largest of these, the International Standards Organization (ISO), was founded in 1947, has members from 162 countries and operates in almost 200 countries. The American Society for Testing and Materials (ASTM) predates the ISO and was founded in 1898. Initially an organization focusing on the U.S., in 2001 the name was changed to ASTM International and the group now develops and promotes technical standards in almost 150 countries. ISO and ASTM International have banded together and developed the Additive Manufacturing Development Structure (AMDS), that will aim to provide technical standards across the board.

The framework will help guide the work of global experts and national standards development organizations, as well as identify standards-related gaps and needs in the AM industry. It will also prevent overlap and the duplication of efforts in standards development, and improve usability and acceptance among the AM community, including manufacturers, entrepreneurs, consumers, and others with a stake in the industry.

“This structure will help experts worldwide interact in a more streamlined and meaningful way, leading to the integration and application of new technologies at an accelerated rate,” said Carl Dekker, president of MET-L-FLO Inc., and chair of ASTM International’s committee on additive manufacturing technologies. “In the future, we could see even more benefits, such as uniform workforce training and a stronger ability to focus on constant quality improvement rather than potential confusion surrounding specifications.”

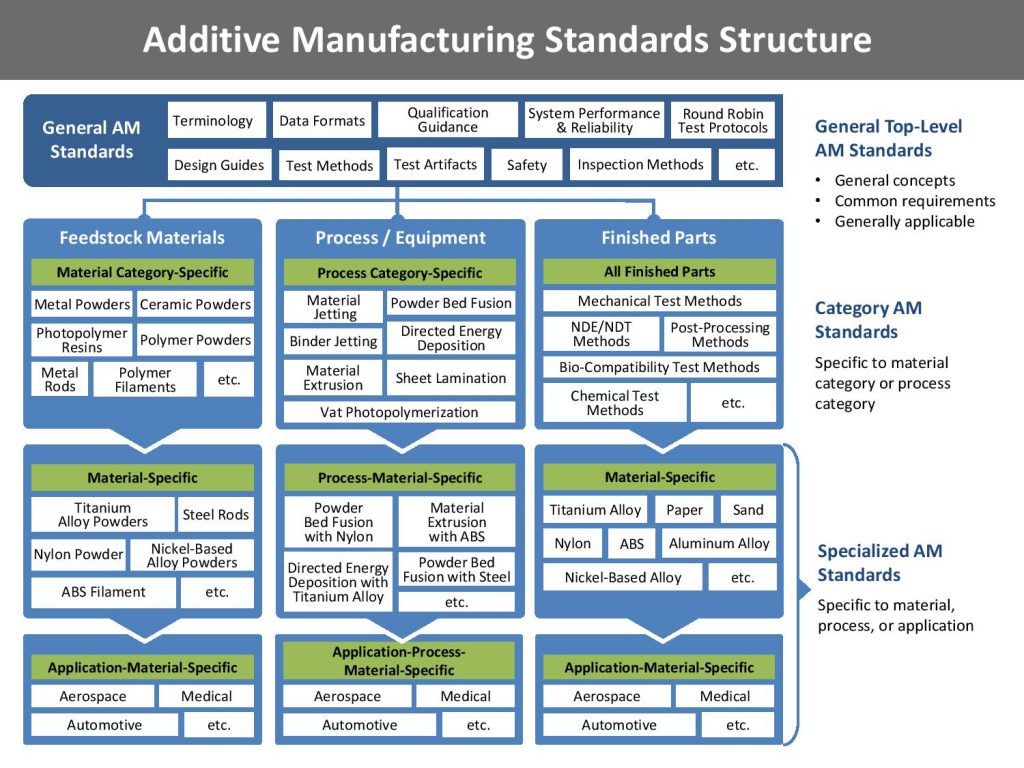

The framework can be used to develop standards at three levels:

- general standards (concepts, common requirements, guides, safety);

- standards for broad categories of materials (metal powders, for example) or processes (like powder bed fusion); and,

- specialized standards for a specific material, process or application (such as aerospace, medical or automotive).

The structure was jointly approved after a meeting in Tokyo in July, and a companion guide is being developed. This will accompany the framework, which does not aim to confine developments, but instead will help standardize them.

“This coordinated approach to standards development in AM is crucial to building out robust standards at all levels,” said Jörg Lenz, collaborative projects coordinator at Electro Optical Systems and chair of ISO Technical Committee 261 on additive manufacturing. “Standards developers can see how this new structure allows them to come together, leading to further innovation in fields like aerospace, medical, and automotive, and also other benefits such as a platform for certification activities.”

To stay up to date with all the latest 3D printing news, join our newsletter here.