This week 3D Printing Industry are at the 3D Medical Expo and related conferences.

We take a look at some of the insights from the 3D Bioprinting and 3D Dental conferences held as half of the four-part expo in Maastricht this week.

Electric control of cellular patterns

In a presentation on High Resolution Biomaterial Printing, Dr. Yan Yan Shery Huang from the Department of Engineering at the University of Cambridge demonstrates the method of Low-Voltage Electrospinning Patterning (LEP).

As the name suggests, LEP is capable of adding a cellular pattern onto existing surfaces such as glass slides, hydrogels, and silicone. It prints at the definition of a single micron, making the pattern smaller than the size of a typical living cell.

Migration of epithelial cells in LEP structures. Slide from: Liu, Gill & Huang Future Medicine (2017)

Once a substrate, i.e. a hydrogel, is patterned with the LEP to mimic a structure like collagen (one of the most prolific substances in the body), living cells are introduced to the structure and assessed for their behaviour.

Examples of cell migration are given in the short clip above. In each pattern, from the looping lines seen on the left, to the box in the middle, and the parallel lines on the right, the cells become trapped.

This behavior is key to studying how, for example, cancerous tumors form and proliferate.

Integration into microfluidics and 3D bioprinting

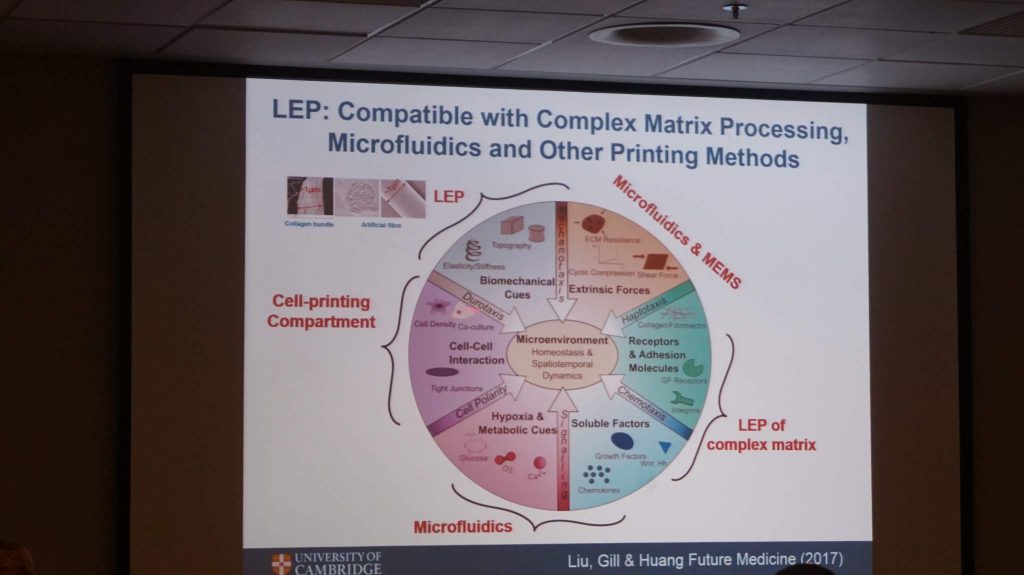

Dr. Huang went on to discuss how LEP is a smaller part of the larger goal to create a faithful microenvironment to study cells outside the body. At present, a typical in vitro microenvironment requires six things for stability:

• Extrinsic forces i.e the exterior pressures from the environment

• Receptors & adhesion molecules – connection cells in-between molecules

• Soluble factors – affecting cell growth

• Hypoxia and metabolic cues – essential nutrients

• Cell-cell interaction

• And biomechanical cues – i.e. the material of a cell-scaffold

As seen in the diagram below, LEP can help with fabrication of 3 of the 6 key factors, and the other 3 rely on collaboration from other methods, such as microfluidics (manipulation of sub-millimeter flow of liquid) and the direct 3D bioprinting of cells.

Polymers for dentistry

In a presentation on Regenerative Polymers for Dentistry Dr. Adam Celiz, research fellow for Marie Curie at the University of Nottingham, presented a material patented by the Wyss Institute for Biologically Inspired Engineering.

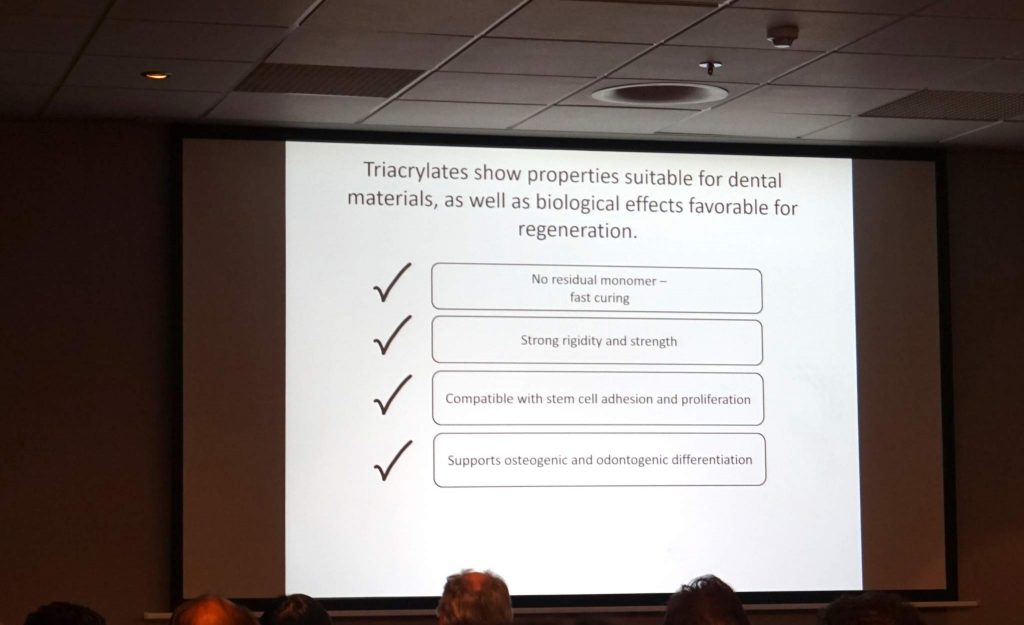

The material uses triacrylates – base monomers found in the structure of plastics. Dr. Celiz proposes the use of triacrylates as an alternative to metallic, i.e. silver or gold, resin and porcelain materials used for tooth fillings.

The main advantages of this approach is that the monomers are activated by living cells within the tooth. Theoretically, this encourages the cells to repair themselves rather than simply filling a void in tooth like in traditional methods.

Though this isn’t a current direction for key players in 3D printing for dentistry, Dr. Celiz does make a key case for triacrylate use as a material reinforcement. It would certainly be interesting to see the material combined with a 3D printable material into a tooth structure.

The studies carried out up until now basically leave the polymer open to manipulation and exploration by other institutions in order to figure out its place within the industry.

3D MedTech and pharmaceuticals

We will have further reports on the 3D Medical Expo tomorrow from seminars specializing in 3D printing’s application for medicine and in medical technology. Be sure to subscribe to our newsletter to be the first to get the news. We’re also posting exclusive photos over on our Twitter account @3Dprintindustry.

Nominations for the first annual 3D Printing Industry Awards are now open.

Featured image shows Mini 3D printed noses (pink) and an ear (blue) in a hydrogel from CELLINK. All photos by Beau Jackson.