There are many fascinating facts about the seahorse. Not only do male seahorses give birth, but these small hippocampus-bearing enigmas also have a strange square shaped tail not often found in fish species. Why? Experiments using 3D printed replicas of the seahorses tail may have finally cracked open one of nature’s great mysteries.

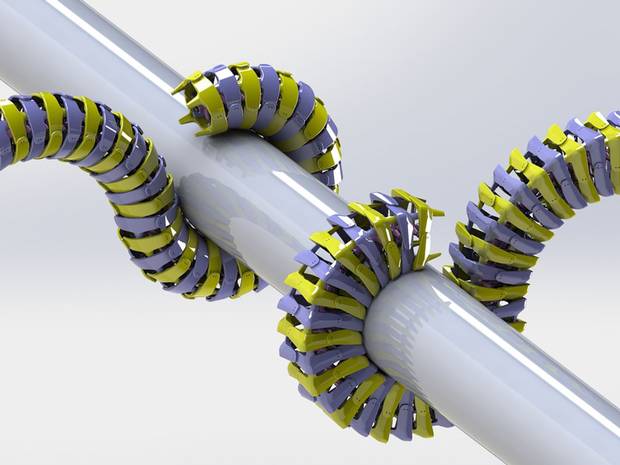

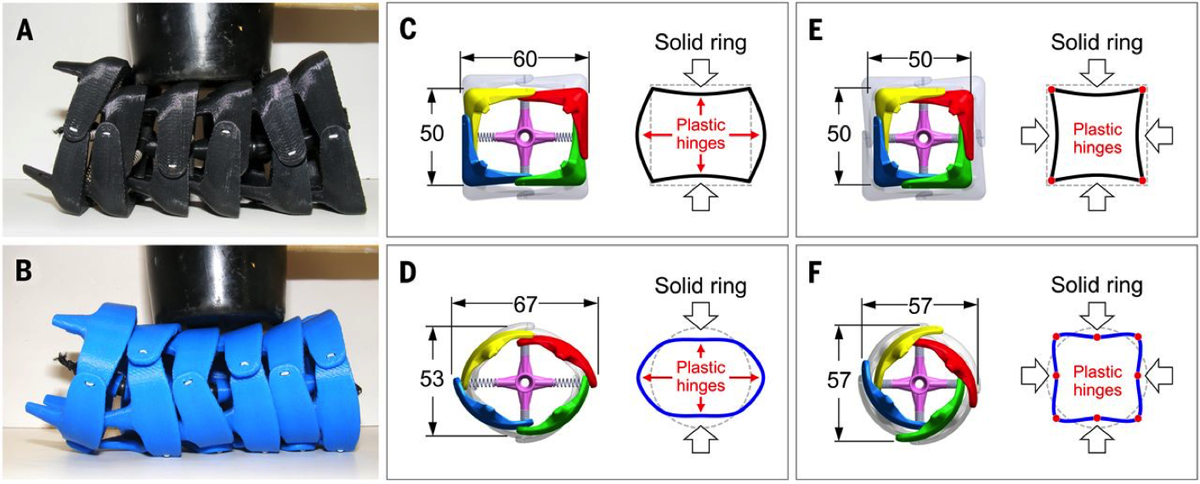

The seahorse’s tail is composed of 36 square segments, and now scientists believe that the strong square-shaped segments actually provide the seahorse with a better grip on corals and seaweed than they would have if they had round tails like many other common aquatic creatures. If something works so well from an evolutionary perspective, why don’t more fish also have square segmented tails? Why only the seahorse?

Michael Porter, a mechanical engineer at Clemson University and the lead investigator on the recent Science journal study says, “We found that the squared-shaped tails are better when both grasping and armour are needed.” It follows that seahorses have different evolutionary needs than many other kinds of fish. Experiments using 3D printed models of square segmented tails reveal that a seahorse’s tail is stronger, more strain-resistant, and mechanically stiffer than the cylindrical tails of your Average Joe sea creature.

Their tails protect seahorses from being caught by their main predators, wading birds. If a seahorse’s tail was not so strong, they could easily be crushed by the birds and easily caught, but research with the models seems to show that when the square tail is crushed, the segmented plates just slide past one another and actually absorb the force of the attack. This helps protect the seahorse’s spinal column from being fatally harmed. When the model of the tail was released from the predators grasp, the segments quickly snapped right back into place, requiring little energy expenditure on the part of the seahorse.

The other advantage of the square segmented tail seems to be the firm grip it gives the seahorse on whatever fixed objects it needs to get a hold of. Experiments with the 3D printed tail model prove that the square shape works much better than the rounded tail as far as allowing the seahorse to retain a strong hold on an anchored object while enduring the ebb and flow of the tide. Scientists mimicked the pull of waves beating against the object and the tail and found that the square segmented tail was better at holding on and resisting the movement of the waves than the round segmented tail.

How can solving one of nature’s riddles help us humans? Scientists are already looking into how they can use this information in medical devices and robotics in order to design devices that are flexible enough to move around bones and organs, but are strong enough to perform surgical operations.

Assistant Professor of Mechanical Engineering at Oregon State University, Dr. Ross Hatton explains, “We found that this square architecture provides adequate dexterity and a tough resistance to predators, but also that it tends to snap naturally back into place once it’s been twisted and deformed. This could be very useful for robotics applications that need to be strong, but also energy efficient and able to bend and twist in tight spaces. Human engineers tend to build things that are stiff so they can be controlled easily, but nature makes things just strong enough not to break, and then flexible enough to do a wide range of tasks. That’s why we can learn a lot from animals that will inspire the next generations of robotics.” Though a lifesaving surgical operation may never be performed by an actual seahorse, you can at least distract yourself with the thought while undergoing your next colonoscopy.