A team of architects and scientists at Hong Kong University (HKU) have developed a novel method of repairing a coral reef in the nearby Hoi Ha Wan Marine Park.

The researchers designed and 3D printed 128 hexagonal clay tiles with complex structures that were custom-made to encourage coral attachment, and deployed them in three sites around the bay. HKU’s artificial reef will be monitored for the next 18 months to ensure its survival, but the team hopes that it could represent an effective method of preventing deterioration of coral reefs across the region.

The growing threat to Hoi Ha Wan Marine Park

In 2018, Typhoon Mangkhut swept across the San Kung peninsula of Hong Kong, destroying 80 percent of Hoi Ha Wan’s corals in the process. The winds, which reportedly reached up to 155 mph, wrecked the flourishing marine ecosystem there, and it could take generations for the reef to recover.

Now, with the added threat of bioerosion, the very survivability of the Marine Park, which accounts for 75 percent of all reef-building corals in Hong Kong, is under threat. In order to better protect the park, and reduce the level of ecological decline there, the Chinese Agriculture, Fisheries and Conservation Department (AFCD) has commissioned a rescue project.

In the program, researchers from the university’s Swire Institute of Marine Science and the Robotic Fabrication Lab have combined their expertise, and worked together to develop a novel method of coral restoration. Having identified the survivability of loose corals as a major factor in the reef’s decline, the team developed three different sets of terracotta tiles with shapes that imitated those of the corals’ natural habitat.

The clay-based structures were deployed at three sites within a 40-meter radius of the park, including the nearby Coral Beach and Moon Islands, as well as a sheltered bay near the WWF Marine Life Center. Using their new terracotta tiles, the team aimed to create a hard base for the corals to rest on instead of the sandy seafloor, preventing them from floating away, and improving their chances of survival.

“Sand is really not great for corals as it can move and bury or scour the coral’s thin tissues,” explained marine scientist David Baker, just before the tiles were dropped in the sea. “Our hope is that the tiles provide a solid foundation for corals to reach a durable size.”

The Hong Kong team’s clay-based innovation

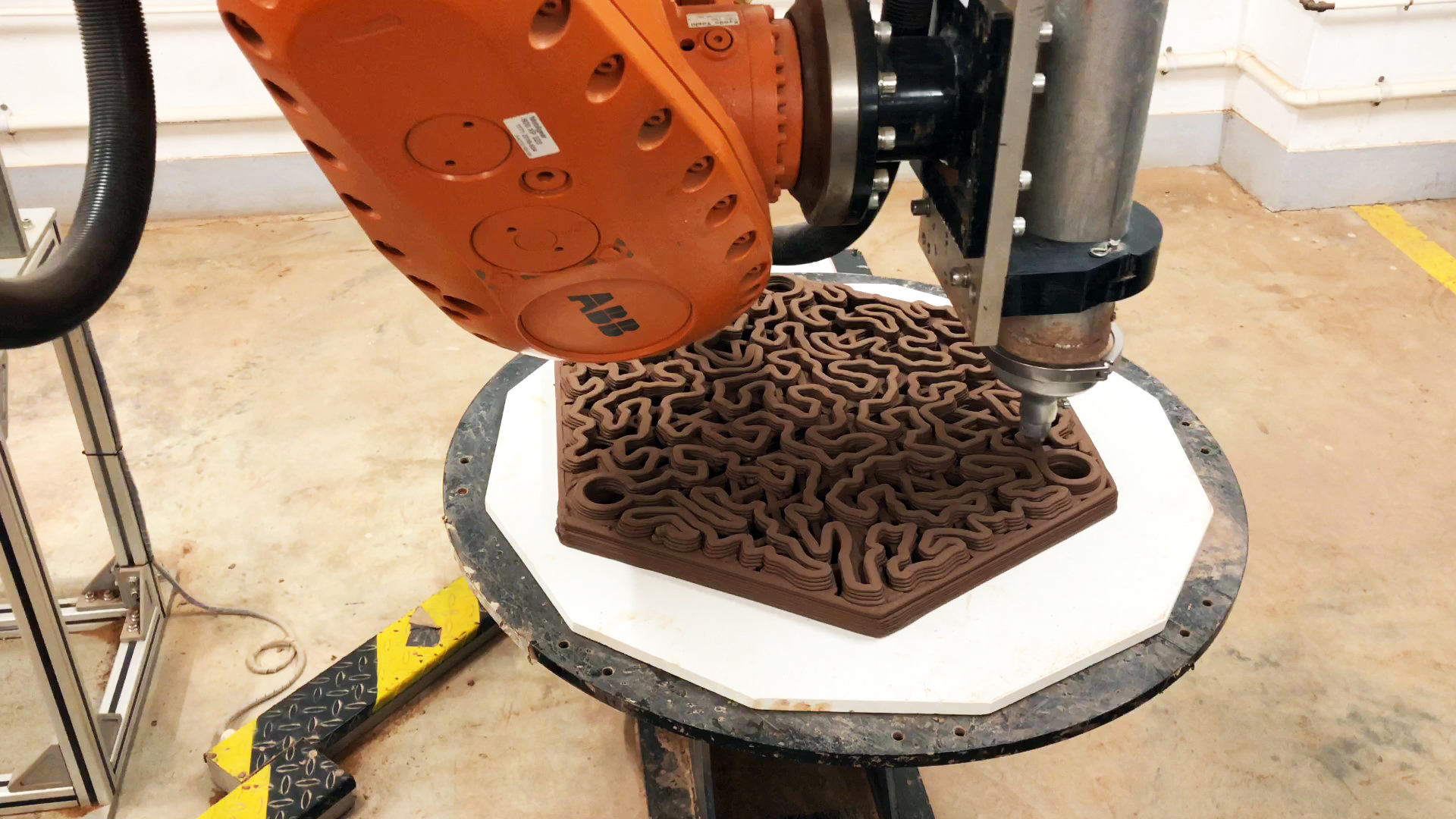

In 2016, to repair the site, the AFCD launched a similar project which utilized plastic nets and fragmentations of healthy living tissues. This time however, they went one step further and used 3D printing instead. Leveraging a clay-based printing process, the team was able to use more eco-friendly materials than conventional concretes or metals to create their tiles, and this prevented them from causing any further damage to the reef.

A total of 128 tiles were produced for the mission, using a combination of terracotta materials, a robotic clay system and a kiln, in which they were blazed at a temperature of 1125 ℃. Each structure, measuring 65cm across and weighing 20kg, was fitted with six ‘legs’ to avoid sedimentation, and featured a nine-grade layer to facilitate coral attachment.

The structures were later seeded with one of three fragments from the most common corals in the bay, including the branching ‘staghorn’, the Platygrya ‘brain’, and the Pavona foliose ‘plating’ colony forms. With this seeding process, the researchers were able to make the corals look like their natural counterparts, and to create a diverse habitat in which other marine species could prosper as well.

Evaluating the team’s 3D printed tiles

Eventually, the team aims to test its tiles through monoculture, polyculture, and mix-culture evaluations. The researchers will examine the reaction of a specific site to one fragment of the coral species, then multiple fragments will be evaluated, before a final check where they’re all tested together.

The researchers will also carry out quarterly checkups for the next 18 months, in which they will collect and examine data from the tiles to identify patterns. Ultimately, the team is hoping that their new reef tile recovery method will help to restore the coral reef in Hoi Ha Wan, and contribute to the broader effort to save marine systems across the region.

“It’s encouraging that we see many species like small fish and crabs taking refuge in the tiles almost as soon as they touch the seafloor,” said Baker. “My hope is that the government will allow us to plant patch reefs that within my lifetime could be significant biodiversity hotspots, enjoyable dive sites, and contribute to increasing corals within Hong Kong.”

3D printing and protecting coral reefs

3D printing has consistently been used by researchers in recent years to maintain marine wildlife enclosures through encouraging algae growth, printing seeds, and extensive monitoring.

In an interview with 3D Printing Industry, Aric Bickel, Operations Manager at SCORE International explained the advantages of 3D printing seed units. According to Bickel, additive manufacturing has allowed SCORE to rapidly prototype their designs, and “create basically anything they could conceive of.”

Researchers from the University of Cambridge and UC San Diego have 3D printed bionic coral structures that are capable of growing communities of microscopic algae. The intrinsic precision of additive manufacturing allowed the researchers to accurately mimic the intricate structure of the corals.

Elsewhere, scientists from Florida Atlantic University (FAU) and the US Office of Naval researchers have 3D printed soft robot jellyfish that are capable of monitoring fragile coral reefs. The team’s study highlighted that “many different aquatic animals have provided inspiration for novel robot design features.”

Nominations for the 2020 3D Printing Industry Awards are still open, let us know who is leading the industry now.

The fourth edition of the 3D Printing Industry Awards Trophy Design Competition is now underway. Enter your design for the chance to win a CraftBot Flow 3D printer.

To stay up to date with the latest 3D printing news, don’t forget to subscribe to the 3D Printing Industry newsletter or follow us on Twitter or liking our page on Facebook.

Are you looking for a job in the additive manufacturing industry? Visit 3D Printing Jobs for a selection of roles in the industry.

Set featured image shows researchers placing the 3D printed terracotta tiles on the seafloor. Photo via Hong Kong University.