Swedish software developer Hexagon AB has completed the acquisition of CADS Additive GmbH, a metal additive manufacturing software specialist. CADS Additive’s software aims to simplify the build preparation and slicing process for powder bed fusion (PBF) 3D printing.

Partnered with Hexagon since 2021,this full acquisition will now see CADS Additive operate as part of Hexagon’s Manufacturing Intelligence Division.

This acquisition will see CADS Additive further integrate its specialized computer aided design (CAD) tools into Hexagon’s software portfolio. It is hoped that their shared development roadmaps will further improve workflows, and allow customers to easily adjust the orientation and support structure of their 3D prints.

CADS Additive claims that this will shorten the additive manufacturing process, offering easy-to-follow steps to limit quality implications caused by changes to orientation or support structures.

“Our investments reflect the growing importance of additive manufacturing, which has huge potential but has been held back by a fragmented ecosystem that means manufacturers are not getting the results they need fast enough”, Commented Hexagon President and CEO Paolo Guglielmini. “The acquisition of CADS Additive enables us to provide our customers with integrated tools that empower manufacturing teams to reduce waste and increase efficiency as they move from prototyping to production.”

Integrating CADS Additive into Hexagon software

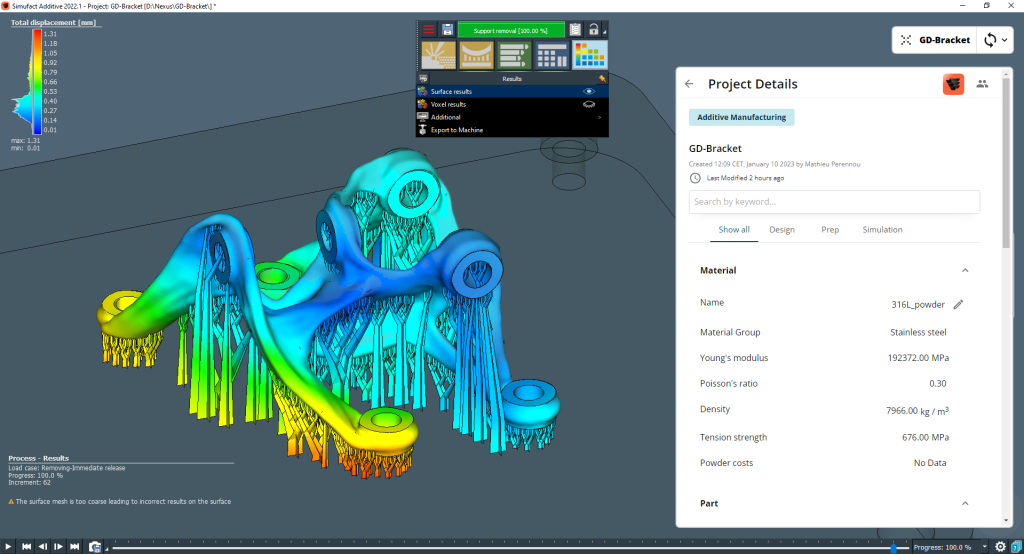

CADS Additive has already integrated its build preparation and support structure creation tools into Hexagon’s Simufact Additive process simulation software.

Additionally, CADS Additive’s AM Studio software is already connected to Hexagon’s Nexus digital reality platform. CADS Additive claims that their software will complete Hexagon’s Nexus-enabled additive manufacturing workflow.

Launched in February of this year, Nexus facilitates real-time collaboration between engineering and manufacturing teams across the lifecycle of a 3D printed product, from design and engineering to production and quality-control.

Upon launch, Nexus included three apps: a metrology reporting app; a cloud-based library for material data; and a material simulation app. A Design for Additive Manufacturing (DfAM) workflow is also included, and is billed as the platform’s first “solution.” Hexagon claims that new apps and “solutions” will be continuously added to Nexus over the coming months and years.

“Opening up the Nexus platform to our ecosystem partners and providing building blocks like CADS Additive helps customers improve their processes throughout the manufacturing value chain and realize the potential of industrial additive manufacturing,” stated Guglielmini.

Software to optimize additive manufacturing

Away from Hexagon and CADS Additive, the 3D printing industry has seen a number of new software offerings to optimize the 3D printing process.

Earlier this year, Materialise, a global leader in 3D printing software and services, released its Process Control Software for metal 3D printing, and the Build Processor Software Development Kit (BP SDK). Utilizing artificial intelligence (AI) technology, Process Control provides automated analysis and correlating data from the 3D printing printing process. This allows users to quickly and easily identify issues prior to post-processing and quality inspection.

Additionally, the BP SDK offers a fixed method to construct and modify build processors (BPs). BPs handle 3D printer-specific data and allow users to modify build settings. This impacts the speed at which a 3D print job can be completed, and defines components attributes such as density and surface quality.

Elsewhere, workflow management software specialists Authentise recently announced Authentise Threads, a new work thread collaboration suite combining project management and communication tools. Authentise claims that this new offering enables more fluid and productivity R&D and engineering workflows for a quicker return on investment (ROI).

“Authentise Threads balances the flexibility of real-time collaboration needed to adapt to rapidly evolving challenges, with the structure needed to make engineering workflows a success,” claims Authentise CEO Andre Wegner.

Subscribe to the 3D Printing Industry newsletter to ensure you keep up with the latest 3D printing news. You can also follow us on Twitter, like our Facebook page, and subscribe to the 3D Printing Industry Youtube channel to access more exclusive content.

Are you interested in working in the additive manufacturing industry? Visit 3D Printing Jobs to view a selection of available roles and kickstart your career.

Featured image shows Hexagon’s Simufact Additive platform being used to analyze a part. Image via Hexagon.