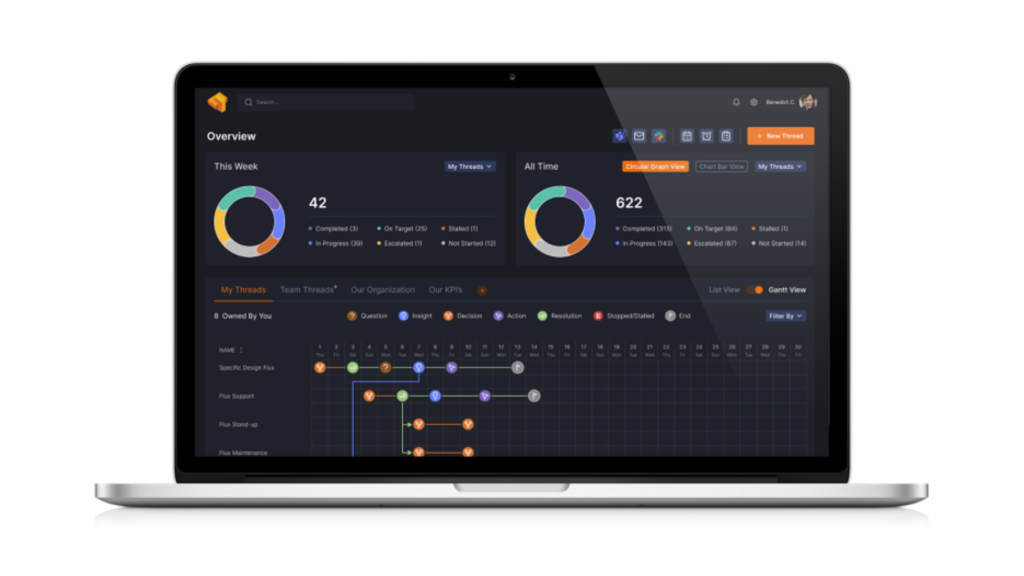

Workflow management software specialists Authentise has announced Authentise Threads.

This new digital offering combines project management and communication tools into a new work thread collaboration suite. Autheintise claims that this allows for more fluid and productive R&D and engineering workflows, enabling a quicker return on investment (ROI).

Able to work in conjunction with existing engineering and project management systems, Authentise Threads offers a number of key features. These include cross functional work thread collaboration; shared information, knowledge, experience, resources and context; collaborative digital decision making; and continuous learning and improvement.

“Despite the noise about the need to be more agile, it’s clear there’s a relative lack of software solutions available today to support R&D, industrial engineering and manufacturing to actually accomplish this,” claims Authentise CEO Andre Wegner.

“Authentise Threads balances the flexibility of real-time collaboration needed to adapt to rapidly evolving challenges, with the structure needed to make engineering workflows a success. With it, Authentise is completing its vision of helping companies digitally track, power and integrate the idea-to-part process,” added Wegner.

What does Authentise Threads offer?

Authentise claims that their new digital thread offering can turn R&D and engineering teams into “innovation engines.”

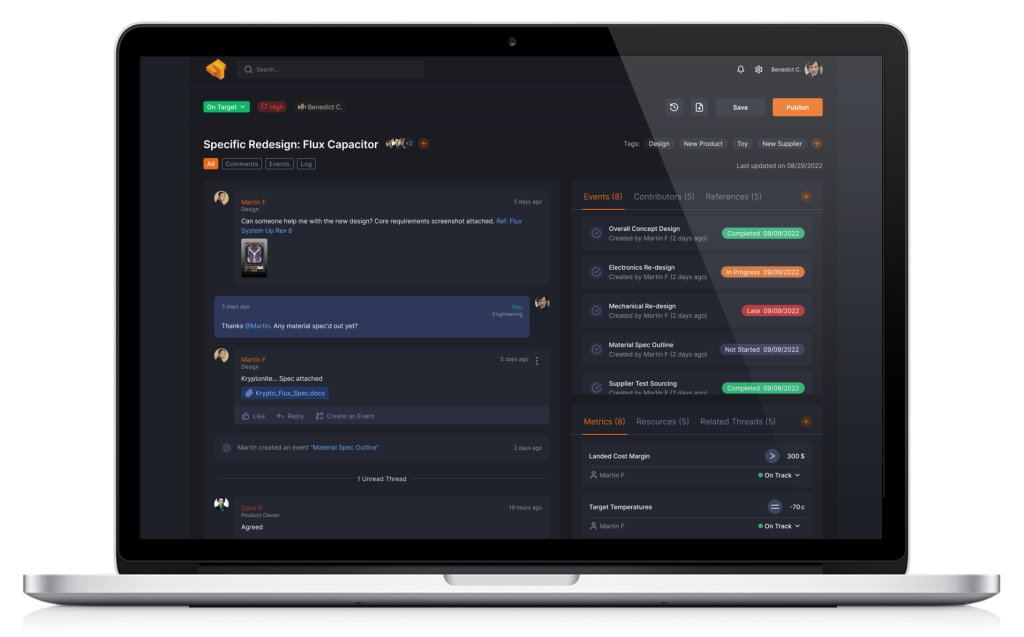

The cross function work thread collaboration capabilities allow users to create, search, follow and link work across partners and engineering teams. Real-time structured communication, notifications, and chat functions are also added, allowing for more accessible collaboration.

Authentise Threads also includes a shared database of the key data, resources, goals, and metrics needed for efficient work thread execution. Users can also track and manage work thread tasks, insights, actions, decisions and resolutions through the collaborative digital decision making tools.

This new platform also allows users to share the full history and traceability of their work. This allows for continuous learning and improvement throughout a project. Discussions, issues, decisions, actions, and metrics can all be tracked with full context.

Authentise Threads has already been acquired by a selection of customers. According to Authentise, the digital thread tool has been utilized by a R&D organization for a “leading surgical robotics company.” It is claimed that the customer had the system set up in under 30 minutes, and was seeing a 1.5x return on their investment within 2 weeks. Tracking 100% of their R&D decisions digitally, the company is said to have saved 150 hours and 20 meetings across a distributed team which included external partners. As a result, Authentise claims that they were able to “double the effective size of their team.”

In total, 90 organizations have provided feedback on Authentise Threads. One such organization is the National Composite Centre (NCC).

Amit Visrolia, Chief of Digital Engineering for the NCC, stated that “Authentise Threads provide us with a place for people to communicate and for data to be connected. With Threads decision processes, and their context, are captured, which is critical to our ability to demonstrate certification. Essentially, with Threads we’ve a people and communication work chain.”

Software to optimize 3D printing

The 3D printing industry has recently seen a number of companies launch digital platforms designed to streamline and optimize the additive manufacturing process.

Earlier this year, industrial software specialists Hexagon AB launched Nexus, a digital platform offering optimized workflow and Design for Additive Manufacturing (DfAM) tools. Co-engineered with Microsoft, Nexus enables real-time collaboration between engineers and manufacturers across the entire life-cycle of a product.

A key aim of Nexus is to “help people overcome data siloes,” and empower customers to “use AM sooner and with greater results,” according to Mathieu Pérennou, Director Additive Manufacturing Solutions, Hexagon Manufacturing Intelligence.

Elsewhere, Montreal based high temperature 3D printer manufacturer AON3D recently unveiled their new machine learning-driven thermal optimization software. Built for Material Extrusion (MEX), this digital tool provides fast and accurate predictions on an object’s heat flow behavior during the 3D printing process. According to AON3D, the software offers potential for cost cutting, improved part reliability and consistency, better technical decision making, and performance optimization.

Subscribe to the 3D Printing Industry newsletter to ensure you keep up with the latest 3D printing news. You can also follow us on Twitter, like our Facebook page, and subscribe to the 3D Printing Industry Youtube channel to access more exclusive content.

Are you interested in working in the additive manufacturing industry? Visit 3D Printing Jobs to view a selection of available roles and kickstart your career.

Featured image shows the Authentise Threads overview screen. Image via Authentise.