As you get to know Afinia, you learn that a lot of their customers come with stories that warm the cockles of your heart. Most recently, Afinia relayed the story of one of their Afiniacs, Glen Risberger, who used an Afinia H-Series 3D printer in his work mentoring a local high school robotics team called Gladstone Robotics.

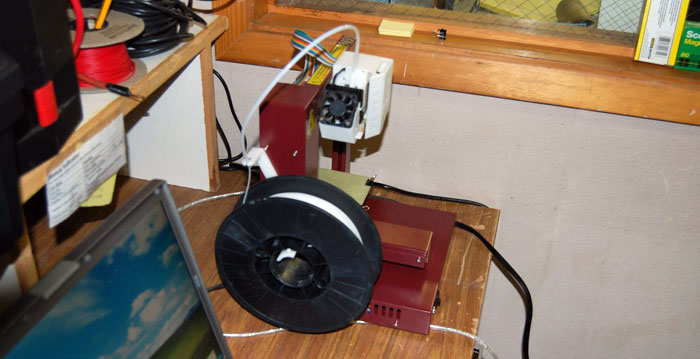

Glen thought that a 3D printer might aid the Gladstone Robotics team, participating in a program known as FIRST (For Inspiration and Recognition of Science and Technology), in creating custom robots parts. Like many people who picked up Make Magazine’s “Ultimate Guide to 3D Printing” in 2012, Glen was convinced by Afinia’s “Best Overall Experience” award, saying, “There were lots of kits available. We decided that we would rather build robots than a 3D printer so we started investigating ones that were already built… It was obvious to us that the Afinia was our best choice. The reviewers said that the Afinia was easy to set up and use. They were right – we were printing in about 20 minutes after opening the box.”

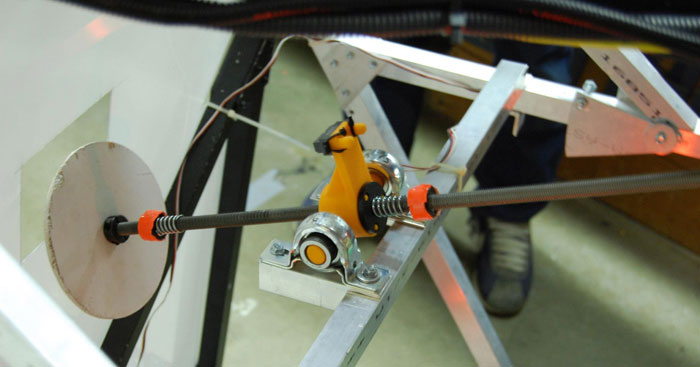

The challenge that the students faced was to design the best frisbee throwing robot, with the greatest accuracy to a specific distance, for a FIRST contest titled Ultimate Ascent. Glen explains that most of his team’s competitors modelled their robots after baseball pitching machines “with counter-rotating wheels”, but anyone who’s played frisbee knows that a frisbee should be thrown parallel to the ground. Glen says, “We came up with a much simpler idea and based ours upon a skeet thrower, which serves a very similar function.” The team was then able to use their 3D printer to build a variety of parts for their robot in a very short space of time:

Glen and his robotics team are clearly a tech-savvy bunch. Autodesk, one of the team’s sponsors, has five summer internships a year, with 40 to 50 students fighting for those spots, but, thanks to his students’ familiarity with designing in Autodesk, two of his team members were easily accepted into the program.

At the same time that 3D printing has helped them through frisbee-throwing robot competitions, it’s also worked as a great marketing tactic – something we’re well aware of at 3DPI. The team partners with a nearby Radio Shack – a chain that readily supplies Afinia 3D printers – and performs outreach in front of the store, with Glen saying, “We really draw people in – they just love to see how the printer works and what the possibilities are. It’s been great for our recruitment effort.” Even the local Community Education group has increased understanding about 3D printing, teaching 30 classes, filled to the brim with students, over the past three months. The program consists of four two-hour classes over four days.

Glen’s story, as unique as it is, could become an everday one. After taking a look at the Ultimate Ascent contest, which has a pretty impressive YouTube channel for a contest geared towards high school students, I can see the beginning of a cultural transformation taking place. Given the right tools, like 3D printers, and the right encouragement, from mentors like Glen, we could shift the goals of young people from becoming famous pop stars to becoming scientists and engineers. We could shift our media from gossip and drama to students building robots to throw frisbees. And, personally, I can’t think of anything better than a world (after solving the problems of world hunger, climate change, etc.) obsessed with building the next best frisbee throwing robot.

All Photos from the Gladstone Robotics Facebook Page