In this edition of Sliced, the 3D Printing Industry news digest, we cover the latest business developments, partnerships, and acquisitions in the additive manufacturing sector.

Today’s edition features the latest 3D printing hardware, software and material launches from Formnext 2021, alongside new additive manufacturing partnerships, sustainability announcements, and business updates announced during the show.

Read on for the most recent updates from Essentium, Digital Metal, Safran Group, Hexagon, 6K Additive, Rapid Shape, Additive Industries, Prusa Research, and more.

New 3D printing partnerships from Hexagon, 3DGBIRE, 6K Additive, Stratasys, TRUMPF, Covestro, GE, and iMakr

A plethora of 3D printing partnerships were announced last week during Formnext 2021.

Kicking things off, Sweden-based global technology company Hexagon has partnered with Directed Energy Deposition (DED) 3D printer OEM Sciaky to enable its customers to optimize how they use Sciaky’s Electron Beam Additive Manufacturing (EBAM) process for high-value parts in G-code before deposition, with accurate high-speed simulation and analysis.

At Formnext, Hexagon also revealed plans to build the industry’s “most flexible and open” additive manufacturing ecosystem to help overcome complexities in 3D printing processes. The firm announced several new additions to the ecosystem, including Sciaky, Meltio, CADS Additive, AMcubator, and Additive Center, with more expected to follow. Formnext also saw Probeam launch its new PB WEBAM 100 machine powered by Hexagon’s technologies that can 3D print high quality parts from challenging materials like pure copper and titanium.

Elsewhere, long-standing Irish Print Services company IPS has partnered with service provider 3DGBIRE to expand its technology portfolio to include 3D printing devices and applications. The two companies have formed a reseller partnership based on the provision of Raise3D products to the Irish market for manufacturing parts and prototyping applications.

6K Additive, a producer of industrial materials for the 3D printing sector, has announced a strategic partnership with 3D printer manufacturer Freemelt to develop and bring to market new materials for the company’s Electron Beam Powder Bed Fusion (E-PBF) printer platform. The partnership will enable new material options for customers within the aerospace, hypersonic, and medical sectors for applications demanding high-performance material properties.

Meanwhile, 3D printer OEM Stratasys has teamed up with Danish shoe manufacturer ECCO to innovate the footwear manufacturing sector. ECCO will leverage Stratasys’ Origin One 3D printing technology to accelerate its product development and review conceptual samples earlier in the development cycle using 3D printed molds with resin materials from Henkel Loctite. The 3D printed molds are faster to produce and cost significantly less than CNC machining aluminum.

German machine tool manufacturer TRUMPF announced it is working with 3D printing powder producer Equispheres to qualify the firms powders on its 3D printers.

“TRUMPF’s engineering team is working to determine the optimum parameters for faster production of aluminum parts with Equispheres’ powders,” said Thomas Bloor, Head of Global Business Development for Equispheres. “This will allow customers to reduce production costs for 3D printed parts and opens the door for more broad adoption of additive production in global manufacturing.”

Polymer 3D printing specialist Covestro and German 3D printer manufacturer voxeljet announced they are working together to develop a material-machine combination for more economic large-series 3D printing. Having previously developed and qualified a thermoplastic polyurethane (TPU) powder for voxeljet’s HSS process, the companies are now expanding their partnership to provide a material-process offering using voxeljet’s large format VX1000HSS printer platform and Covestro’s functional material expertise.

Elsewhere, the US Air Force and GE have entered Phase III of their metal additive manufacturing pathfinder, as part of the Pacer Edge Program to tackle the Air Force’s ‘cold starts’ issue – engine components that take more than 300 days to procure. Over the next five years, the partners will create at least five technical data packages across the Air Force’s sustainment platforms.

“The first priority for the USAF and GE team has been to create digital 3D technical data packages for hard to procure, obsolete ‘cold start’ parts and deliver four airworthy, near-net castings,” said Alexa Polites, US Air Force Pacer Edge Program Manager, GE Additive.

“These TDPs will eventually mean that part obsolescence will be a thing of the past.”

3D printer, scanner, and services reseller iMakr and additive manufacturing composites firm AREVO have joined forces to offer large-scale continuous carbon fibre additive manufacturing. AERVO’s machines are capable of printing precise, lightweight and ultra-strong parts up to 1 cubic meter in size, and can reportedly scale production up to tens of thousands of units.

Rounding off the Formnext 2021 partnership news is the agreement between German 3D printer manufacturer Rapid Shape and Forward AM, the 3D printing arm of BASF, to offer workflows for their material-machine systems. Rapid Shape will offer validated workflows for printing Forward AM’s high-performance materials on its Digital Light Processing (DLP)-powered 3D printers.

New 3D printers at Formnext 2021 from Industrial Supplies, Additive Industries and Optomec

3D Printing Industry has already covered a number of the new 3D printer launches during Formnext 2021, including new machines from the likes of 3D Systems, BigRep, Zaxe, WASP, LOOP 3D, Shining 3D, Axtra3D and others.

Also announcing new hardware at the show was Industrial Supplies, part of the Smart International Group, which launched its new Macro Production Module for flexible, on-demand low-volume production. Featuring four individual print chambers which can come as standard or high-temperature, the module works with a wide range of high-performance materials like PEEK and ULTEM. The chambers can either be used individually for specific projects or together to increase production capabilities.

Meanwhile, Netherlands-based metal 3D printer manufacturer Additive Industries presented a number of new products at last week’s show, including its new MetalFAB G2. Available in three versions – Core, Automation and Continuous Production – the next-generation machine has more than 150 updates and features optimized gas flow and heat management, updated process parameters and automated beam quality measurements.

Additive Industries also unveiled a new MF Calibrate multi-beam qualification tool to ensure repeatable and predictable output, and its Additive Studios offering for services in the field of applications, DfAM and optimizing build strategies and process parameters. The company announced an additional partnership with Sigma Labs through integrating the software developer’s PrintRite3D melt pool monitoring analytics and monitoring tool.

Alongside launching its first desktop 3D printer at Formnext, high-speed resin 3D printer developer Nexa3D also announced the pre-launch of its QLS 350 SLS system at the show. Initially popping up at RAPID+TCT 2019 as the NXT Factory QLS 350, the machine decouples the printing and cooling processes in order to maximize uptime, achieving a speed of eight liters per hour and 20 percent job density. The machine is designed with speed and throughput at the forefront, featuring four 100W CO2 lasers that enable users to achieve up to four times the print speed of traditional laser sintering technologies.

Finally, industrial 3D printer manufacturer Optomec announced two new 3D printers at last week’s trade show designed for high-volume production. The first, the HC-TBR, is an all-in-one metal 3D printer powered by the firm’s LENS DED technology for the building or repairing of metal 3D printed parts. The machine can process reactive metal alloys like titanium and aluminum at high volume in an oxygen-free chamber and is designed to provide lower-cost methods of producing and repairing titanium components.

The second machine launched by Optomec is the Aerosol Jet HD2 3D Electronics Printer, designed for 3D semiconductor packaging and assembly. The printer leverages Optomec’s patented Aerosol Jet process to produce high-resolution circuitry with features as small as 10 microns and can dispense conformal 3D interconnects between die, chips, components, and substrates. The machine is suited to emerging segments such as 5G communications, automotive radar, and defense applications.

New Materials at Formnext 2021 from Essentium, Stratasys, Digital Metal, EOS, Wematter, Oerlikon, and BASF

In addition to 3D printing partnership and hardware announcements, Formnext 2021 saw multiple new material launches.

Essentium, the manufacturer behind the High Speed Extrusion (HSE) 3D printer series, introduced Essentium PPS-CF, a 15 percent carbon fiber-reinforced polyphenylene sulfide (PPS) filament made with LUVOCOM 3F resin from LEHVOSS Group. With an excellent price-to-performance ratio and desirable strength, stiffness, temperature, chemical and wear resistance properties, PPS-CF is the primary tooling material for injection molding, blow molding and thermoforming processes.

Essentium also launched a 5kg spool at Formnext that allows users to continuously print large parts and tools through minimizing the number of spool swaps required and wasted filament. A new mobile app unveiled by the firm will help manufacturers to remotely monitor their 3D printed parts production and provide greater transparency within their processes.

The final Formnext announcement from Essentium concerns the findings of its independent global research on the current and future use of industrial 3D printing. The research reveals that the use of large-scale additive manufacturing has more than doubled in the past year for 86 percent of manufacturing companies, and the technology has evolved from prototyping to becoming an “essential component” in the large-scale production of functional parts.

In addition to its partnership with ECCO, Stratasys announced a new open tier of third-party materials for FDM 3D printers via an annual Open Material License. The company already provides open material availability for its Neo SLA, Origin One, and H350 3D printers, and is now extending this material ecosystem approach to its FDM technology.

The Stratasys Material Ecosystem includes: Stratasys Preferred – designed to provide the best combination of material and printer performance, Stratasys Validated -materials validated by Stratasys with basic reliability testing, and Open – unvalidated materials accessed via an Open Material License. Stratasys-Validated materials will be available to customers during the second half of 2022, starting with the Fortus 450mc.

Swedish metal 3D printer manufacturer Digital Metal has added DM 4140, a low-alloy steel powder, to its binder jetting printing system in order to provide greater design freedom for components exposed to high loads. The company developed and certified DM 4140 in partnership with Hyundai Motors, which used the material to manufacture gearbox control fingers via binder jetting. The material is well-suited for the production of components for automotive, consumer goods, and industrial applications exposed to high loads.

Digital Metal has also added another superalloy to its binder jetting system, DM 718, an equivalent to Inconel 718, which is engineered to withstand extreme temperatures and corrosive environments. The material can be used for applications such as gas turbines, jet engines, rocket engines, turbopumps, and pressure tanks.

Formnext 2021 saw 3D printer manufacturer EOS release a new high-strength, lightweight 3D printing aluminum alloy, Al2139 AM, to significantly reduce part weight without compromising on strength. Delivering excellent performance in temperatures up to 200ºC, Aluminum Al2139 AM is EOS’ highest strength additive manufacturing alloy, achieving a yield and tensile strength of around 500 MPa. Thanks to a single-step heat treatment procedure, firms can reportedly save up to 88 percent in active heat treatment time.

Al2139 AM is ideal for a range of high-performance applications within the aviation, transportation, racing, and space sectors. The material and process for the EOS M 290 is planned to be released in Q1 2022, with other EOS DMLS systems in the pipeline.

Elsewhere, Swedish 3D printer manufacturer Wematter has introduced Aurora PA6 AM, a material engineered to withstand higher temperatures without compromising its mechanical properties. Once cooled, the material’s stiffness and mechanical strength are increased and its base, Polyamide 6, has highly sought after properties within the aerospace and automotive industries.

“Developing new materials and thus being able to broaden the scope of use of the SLS 3D printer Gravity is incredibly important and exciting for us,” said Robert Kniola, Founder, and CEO of Wematter. “Of course, we want Gravity to work for as many people as possible, and, since plastics are used in so many different components, we need to have materials for different applications.”

Swiss technology group Oerlikon presented a new high entropy alloy capable of matching the strength and corrosion resistance of super duplex steels (DSS). Featuring a nanoscale duplex microstructure, the alloy is suitable for the printing of structural components like centrifugal pump impellers due to enabling complex geometries and crack-free parts via LPBF.

Rounding off the material news from Formnext 2021 is a couple of Ultrafuse engineering filaments from BASF, which have now been made available for Zortrax’s M300 Dual 3D printer. Ultrafuse PP GF30, made up of polypropylene reinforced with 30 percent addition of glass fiber, and Ultrafuse PAHT CF15, a polyamide reinforced with 15 percent carbon fiber, are heavily used in the automotive sector for a wide range of components.

The materials can now be used by Zortrax customers to 3D print positioning jigs, assembly tools, and different seals and covers within automotive manufacturing plants.

Software updates from Formnext 2021 from Stratasys, MachineWorks, Authentise, and Materialise

Another update from Stratasys sees the firm introduce its GrabCAD Print software for its SAF-powered H350 3D printer in order to enable users to achieve production-scale quantities of 3D printed parts. GrabCAD Print for the H350 ensures that the end-to-end workflow across the machine is easy, accessible, affordable, and connected.

The software has been upgraded to provide advanced print capabilities, and due to being built on the firm’s GrabCAD Additive Manufacturing Platform, users of the H350 will also have access to Stratasys’ other core applications, including GrabCAD Print Mobile, GrabCAD Shop, reporting, and analytics, and machine connectivity.

3D printing developer MachineWorks has announced the availability of its Polygonica 3.1 SDK software tool for polygon mesh modeling. The headline improvements to the newest version include new .NET wrappers supporting programming with C# and other .NET languages, identification of curves, non-manifold geometry gealing, screw thread recognition, and optimization of mesh export.

“In Polygonica 30 we added significant new areas of functionality,” said Dr. Fenqiang Lin, Managing Director of MachineWorks. “The 3.1 release cycle has seen great efforts to further improve existing functionality in response to customer feedback, and also development of interesting new techniques we believe have lots of potential.”

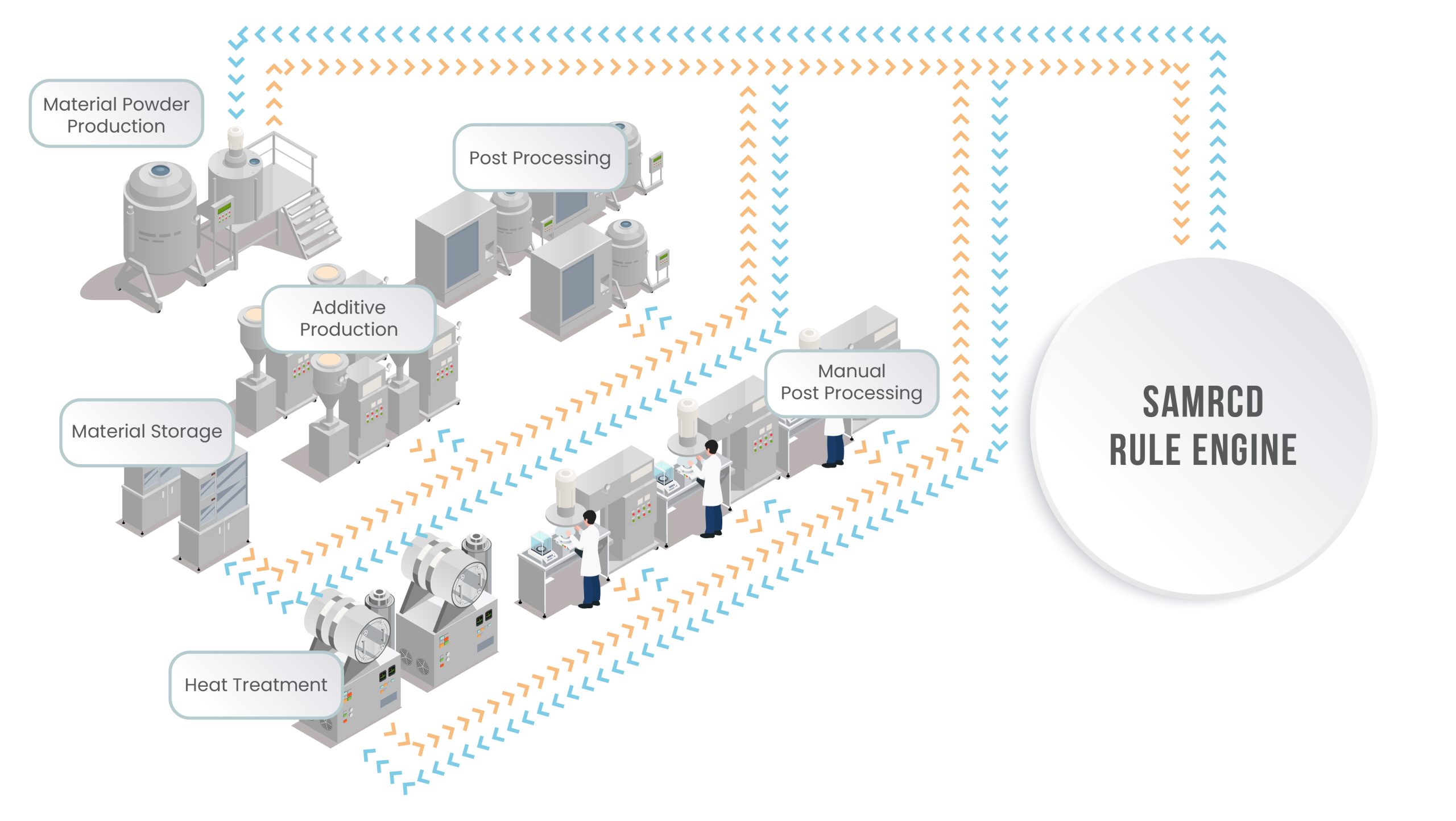

Meanwhile, a consortium led by 3D printing software developer Authentise has received a multi-million-pound grant from UK Research and Innovation (UKRI) to develop new digital tools to extend in-process control from material production to delivery. Throughout the £1.7 million Scalable AM Rule Creation & Dissemination (SAMRCD) project, Authentise and its partners will identify, create, and enforce rules that reduce direct and indirect energy consumption and increase material efficiency within ceramic and metal 3D printing.

Alongside Authentise, Photocentric, ICD, the Materials Processing Institute, and TWI will be helping to create data-driven workflow tools for 3D printing that will enable users to ensure their future production is more efficient and produces repeatable products.

The last of the software updates come from Belgian software and 3D printing service provider Materialise, which is helping companies to optimize and expand their 3D printing operations through embedding a CAD workflow into its Magics software. The latest iteration of the firm’s software platform, Magics 26, is due to arrive in Spring 2022, with Formnext attendees among the first to preview the newest updates last week.

Some of the notable improvements to the firm’s flagship data and build preparation software include a CAD-Kernel integration to advance end-to-end workflows, and new mesh-based operations for platform and build preparation.

“For years, the 3D printing industry has discussed whether CAD or mesh is the preferred workflow for file preparation,” said Stefaan Motte, Vice President Software for Materialise. “We believe both offer unique benefits and a seamless integration of both formats will provide users with the optimal workflow.”

Formnext 2021 business updates

As was to be expected, numerous business updates were announced at Formnext last week, much of which we covered during the show.

In addition, model making and prototyping firm Ogle has purchased an EOS P 770 SLS machine as part of the firm’s ongoing commitment to investing in the latest state-of-the-art machinery.

“Ogle’s investment in the EOS P 770 reflects the company’s ambition to harness the latest technologies to improve our offer to clients and adapt as their requirements change,” said Phil Martin, Ogle Director. “The machine will help us to increase capacity, reduce turnaround times for clients and deliver the highest-quality prototypes. This increasing efficiency and continual improvement in quality is why clients return to us time and time again.”

The American Banknote Corporation (ABCorp), meanwhile, has expanded its Boston-based Center of Excellence to introduce both batch production and enterprise-scale production to the region, leveraging binder jet technology from Desktop Metal. By installing the Desktop Metal Shop System at its 125,000 square foot facility, ABCorp will be able to 3D print end-use metal parts with greatly increased speed and productivity under one roof for both flexible batch jobs and volume production.

Open-source 3D printer manufacturer Prusa Research has acquired an 80 percent stake in Czech 3D printer OEM Trilab in its quest to expand into other areas of the 3D printer market. As well as providing Prusa Research with access to the corporate 3D printing sector, the two companies will cooperate in other areas through the sharing of development, business, and marketing experience.

“Trilab produces high-quality 3D printers for the corporate sector and their brand is very well established in this area,” said Josef Průša, Prusa Research CEO. “Our machines are aimed more towards hobbyists and they are open-source. This approach may be limiting in corporate and industrial sectors.”

In addition to its material launch, EOS also gave an update on its newly introduced holistic sustainability approach. The company discussed its recent Life Cycle Analysis (LCA) conducted with its customer YOU MAWO and Fraunhofer EMI for 3D printed polymer eyewear, and a new inductor design manufactured with EOS Copper CuCP on an AMCM M 290 1kW system for AMCM, an EOS company.

EOS also provided updates on its Additive Minds Academy, new carbon-neutral polymer materials from its subsidiary Advanced Laser Materials (ALM), and a new Carbon Calculator that assesses a final 3D printed part’s carbon footprint. ALM’s carbon-neutral materials are reportedly a first for the additive manufacturing industry, beginning with PA 820 MF CN, a mineral-filled bio-circular polyamide 11 material, and PA 802 CF CN, a carbon fiber-filled bio-circular polyamide 11.

After gaining the option to buy fellow software developer Link3D earlier this year, Materialise has now agreed to exercise this option for $33.5 million. The transaction is expected to close by the end of the year, and is expected to strengthen and accelerate the creation of Materialise’s software platform, particularly for companies that are scaling up their 3D printing operations to volume production. Materialise will integrate Link3D’s MES into its Magics software suite into a unified, cloud-based software platform.

“Materialise continues to lead the way in advancing the AM industry and this acquisition strengthens our position in the high-growth manufacturing market,” said Fried Vancraen, CEO of Materialise. “As companies accelerate the adoption of additive manufacturing into increasingly digital production environments, they require a strong and unified AM software platform.

“Today’s announcement creates a merger of forces that serves as the foundation for such a scalable and sustainable platform.”

Alongside its new 3D printer launches, Nexa3D also unveiled several business-related announcements at last week’s show. The company has partnered with artificial intelligence (AI) software firm Oqton to meet growing global demand for 3D printed patient-specific dental appliance and aligners. The partnership will see the firms unveil a new dental software that delivers productivity gains across the entire dental manufacturing workflow, leveraging Nexa3D’s NXD 200 dental production 3D printer, certified dental materials, and automated post-processing.

Nexa3D also announced a number of key hires to its leadership team, welcoming Nina Swienton as Chief Marketing Officer, Melissa Hanson as Vice President, Product and Marketing Management, Mahdi Mojdeh as Vice President of Engineering, and Michael Currie as Vice President, General Manager Desktop Business Unit.

Meanwhile, 3D printer manufacturer 3D Systems has priced an upsized $400 million debt offering, which closed on 16th November. The net proceeds of the move are expected to amount to around $388 million, and will be used for general corporate purposes, which “may include” potential acquisitions, investments, and strategic transactions.

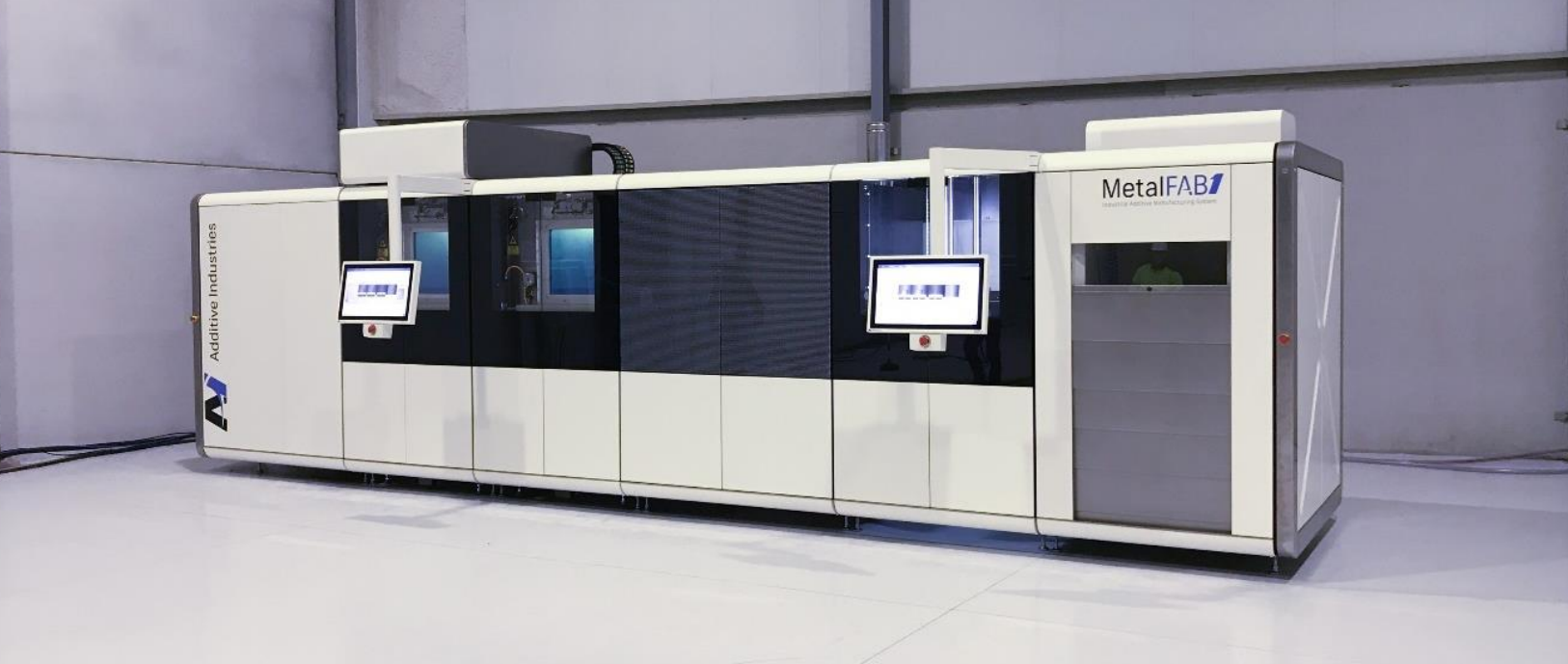

Finally, aerospace and defense firm Safran Group rounds off this week’s bumper Formnext Sliced edition with the successful deployment of a MetalFAB1 industrial 3D printer from Additive Industries. Having installed the printer in June 2021 for testing, the company has since used the system to manufacture highly complex parts for its aviation, defense and space business.

“We are proud to acknowledge that, with the support of their first MetalFAB1, the Safran Additive Manufacturing Centre has been able to produce their first aeronautical parts at their new site,” said Stephane Escalier, Director Business Development France at Additive Industries. “We are looking forward to expanding the range of the applications and materials in this intense and strong collaboration.”

Subscribe to the 3D Printing Industry newsletter for the latest news in additive manufacturing. You can also stay connected by following us on Twitter and liking us on Facebook.

Looking for a career in additive manufacturing? Visit 3D Printing Jobs for a selection of roles in the industry.

Subscribe to our YouTube channel for the latest 3D printing video shorts, reviews and webinar replays.

Featured image shows the Formnext 2021 trade show with the Sliced logo.