Industrial 3D printer manufacturer LOOP 3D has unveiled a ‘fleet’ of new Fused Filament Fabrication (FFF) systems at the Formnext 2021 trade show.

Known as the LOOP PRO X, the firm’s latest printer features a modular configuration that’s specifically designed for ease of maintenance, and allowing users to reduce their machine downtime. When chained together, the systems can also be managed remotely from one location via its CLOUD software, providing adopters with a way of scaling their automotive, healthcare or aerospace part production.

LOOP 3D’s industrial-grade portfolio

Founded in 2010 as a spin-off of Turkish 3D printing bureau Teknodizayn, LOOP 3D is a developer of both conventional and advanced manufacturing machines. The firm’s portfolio is built around the idea that the lack of quality and high cost of adopting many current industrial 3D printers, is creating barriers that are driving would-be users away from in-house manufacturing, and towards service providers.

To help make additive manufacturing more accessible for SMEs, LOOP 3D has therefore committed to making its offering as easy-to-use as possible, via a combination of proprietary software and machines. The company’s inaugural 3D printer, the LOOP PRO, underwent extensive beta testing and went through several iterations in 2017, before being unveiled at Formnext 2019 and brought to market.

These changes saw the firm improve the upgradability of its machine even further, with the introduction of its LOOP 3D ‘Core’ and ‘Connect’ boxes. Launched at the height of the pandemic, the interchangeable devices are designed to make self-servicing the LOOP PRO easier for the company’s customers, while allowing them to scale their production capabilities to meet demand where needed.

Since then, the company has begun to expand its operations, selling its machines in new global markets and deploying them in novel applications. Turkish automotive firm HİDROMEK, for instance, has deployed the LOOP PRO to produce end-use agricultural vehicle parts that allow it to reduce its related machinery downtime and costs.

Alongside its machine offering, LOOP 3D now also markets its DYNAMIDE materials, which have the thermal resistance and durability needed for end-use applications ranging from robotics to 3D printed architecture, as well as its 3DPrinterOS-developed CLOUD software that’s increasingly enabling users to address such industries on a larger scale.

Establishing an industrial fleet

Formally launched at LOOP 3D’s Formnext booth, the new LOOP PRO X is built from the ground up to allow manufacturers to produce parts as flexibly as possible. The machine’s build plate incorporates a magnetic spring steel film, which firmly embeds models onto its surface, providing adopters with a means of achieving highly-consistent results.

Thanks to its 500 x 350 x 500mm build volume, the machine is also able to create large parts in a single piece, saving users from having to bolt together smaller prints, while its modular electronics allow clients to reduce any machine downtime, as its design minimizes any damage caused by issues, avoiding the need for on-site technical service.

“Modular electronic components are designed to minimize the damage of potential issues without creating the need for on-site technical service,” explains Mehmet Erkan Ustaoğlu, CEO of LOOP 3D. “With different box designs that help to categorize the problems, the boxes are maintained according to the problem type. Any potential issue can then be solved very fast without the risk of downtimes.”

When used in tandem with LOOP 3D’s CLOUD software, this resiliency makes the LOOP PRO X ideal for addressing serial manufacturing applications. Leveraging the program, for example, users are able to track their print jobs via the PRO X’s built-in cameras from a remote workstation, or request a time-lapse video of the build instead if desired.

The program now features an ‘expert mode’ too, which unlocks access to all the system’s settings, and enables manufacturers to create their own presets. In doing so, users can precisely control every print-sensitive parameter, including speed, heat and retraction, ensuring that they scale their production without compromising on part quality.

Finally, in terms of material compatibility, the machine is capable of processing the company’s DYNAMIDE CF and GF composite-infused filaments. According to LOOP 3D, these “cost-effective” polymers have “excellent mechanical and physical properties,” making them well-suited to the manufacturing of end-use parts and low-volume production.

Technical specifications and pricing

Below are the technical specifications for LOOP 3D’s LOOP PRO X 3D printer. Those interested can find out more about the machines via the company’s store page, where they can also request a quote if desired, or head to its Formnext booth in Hall 11.0, booth C40.

| Build Volume | 500 x 350 x 500mm |

| Print Bed | Aluminum-heated |

| Default Nozzle Diameter | 0.4mm |

| Layer Thickness | 50 – 300 µm |

| Machine Interface | 7-inch touchscreen display |

| Connectivity | Wi-Fi, Ethernet, USB |

| File Compatibility | .stl, .obj, .3mf |

| External Dimenstions | 770 x 610 x 1550mm |

| Weight | 140kg |

To stay up to date with the latest 3D printing news, don’t forget to subscribe to the 3D Printing Industry newsletter or follow us on Twitter or liking our page on Facebook.

For a deeper dive into additive manufacturing, you can now subscribe to our Youtube channel, featuring discussion, debriefs, and shots of 3D printing in-action.

Are you looking for a job in the additive manufacturing industry? Visit 3D Printing Jobs for a selection of roles in the industry.

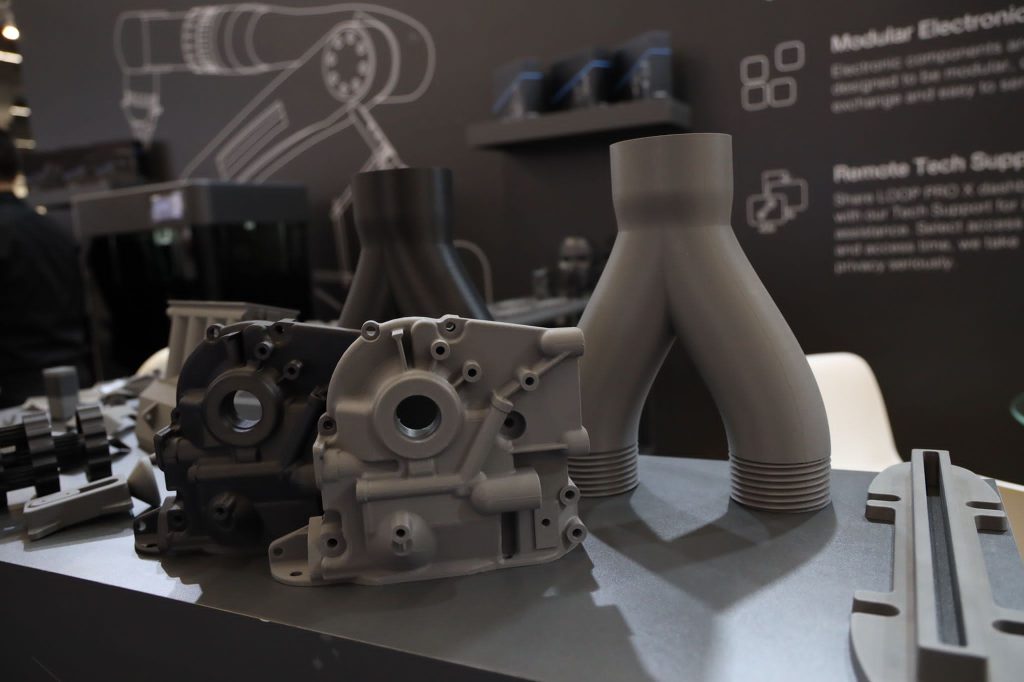

Featured image shows a fleet of LOOP 3D PRO X 3D printers. Image via LOOP 3D.