Formnext 2019 may have been and gone, but there is still news to catch up on. Here is a digest of 3D printing updates from the largest additive manufacturing conference.

Reporting live from the show, backed by a team covering all of the latest press releases from the event, 3D Printing Industry provided leading coverage from the Frankfurt-based exhibition which grew by around 35% from the previous year.

In case you missed it, here we have a roundup of the releases made at Formnext 2019, including new 3D printers from ROBOZE, Essentium, and GE Additive, the latest software releases from Simufact, as well as various materials unveilings.

Business at Formnext 2019

Sintavia, a Florida-based metal 3D printing service, announced it has co-founded a trade group called Additive Manufacturer Green Trade Association (AMGTA) which will focus on manufacturers promoting the environmental benefits of 3D printing. AMGTA is set to be a non-commercial, unaffiliated organization open to all entities using additive manufacturing for sustainable production.

XJet, an Israeli 3D printer and materials manufacturer, partnered with Sharon Tuvia, a global manufacturer of mechanical assemblies and parts to beta test the company’s newest ceramic, Alumina. This material will also be beta tested by an undisclosed U.S. customer.

Italian metal 3D printing service provider BEAMIT, who also announced a partnership with Sandvik at Formnext 2019, acquired its third SLM 500 quad-laser system this year. This brings the company’s total of SLM machines to eight.

German metal 3D printer manufacturer SLM Solutions and Divergent executed a letter of intent to expand its partnership. This will lead to Divergent’s purchase of 5 pre-production jointly developed machines to meet production demand for a number of major global carmaker programs. Divergent’s hypercar was also on display featuring a 3D printed chassis structure.

Farsoon Technologies, a Chinese manufacturer of SLM and SLS 3D printers, declared the first installation of the FS301M to a U.S. aviation customer. Together, the partners have conducted initial qualification tests that show data from on Ti6Al4V Titanium exhibiting industry-leading performance for additive and near-wrought properties.

Lubrizol, an Ohio-based chemicals and materials company, also partnered with Farsoon Technologies to broaden the reach of its TPU-powders. Upon the announcement, David Pascual, Global 3DP Marketing Manager, Engineered Polymers, Lubrizol, stated, “Farsoon’s strength in industrial Laser Sintering Systems motivated Lubrizol to enter into the collaboration.”

Swedish binder jetting metal 3D printer manufacturer Digital Metal also declared a partnership with Elnik Systems, a U.S. manufacturer of metal injection molding (MIM) equipment, and DSH Technologies, to advance metal additive manufacturing.

Kumovis, a German medical 3D printing startup, joined forces with Grapho Metronic to improve Fused Layer Manufacturing (FLM) process monitoring in real-time within the R1 3D printer.

Digits2Widgets, a London-based 3D printing service bureau, has rebranded to Additive on the company’s 10th anniversary.

Material developments

Belgian chemical company Solvay launched Solef® polyvinylidene fluoride (PVDF) MSC NT1 filament to its range of additive manufacturing materials. With this material, Solvay is joining the Ultimaker Material Alliance Program.

Italian SLA 3D printer developer DWS and Global chemical manufacturer Huntsman entered a strategic partnership to give footwear companies, and other industrial manufacturers, access to a new polyurethane-based resin, known as IROPRINTTM R 1801. This material, developed by Huntsman, is said to deliver excellent resolution and high surface quality whilst exhibiting elasticity and strength. DWS worked with Huntsman to optimize IROPRINTTM R 1801 for SLA 3D printing.

Global material producer DSM, Chromatic 3D Materials, and German RepRap have partnered to accelerate the adoption of Chromatic’s line of polyurethane (PU) materials. German RepRap will make its range of 3D printers accessible to manufacturers using Chromatic’s FlexTune elastomer materials, to create durable, flexible complex parts.

Boston-based plasm technology company 6K introduced Onyx In718 premium powder for additive manufacturing. The company also announced a collaboration with Castheon, a US-based additive manufacturing R&D and service company. Together, partners 3D printed what is described as the world’s first metal alloy HEA part on a laser powder bed fusion printer.

Essentium Inc., a Texas-based 3D printer provider, introduced four new high-temperature filaments for its High Speed Extrusion (HSE) platform including PEEK, High-Temperature Nylon (HTN), HTN-CF25 and HTN-Z (ESD safe). The company also debuted the HSE 180•S 3D series, which includes a low-temperature (LT) and high temperature (HT) 3D printer. In addition, Essentium announced it will seamlessly integrate Materialise 3D printing Magics Essentials software with the Essentium HSE 3D Printer.

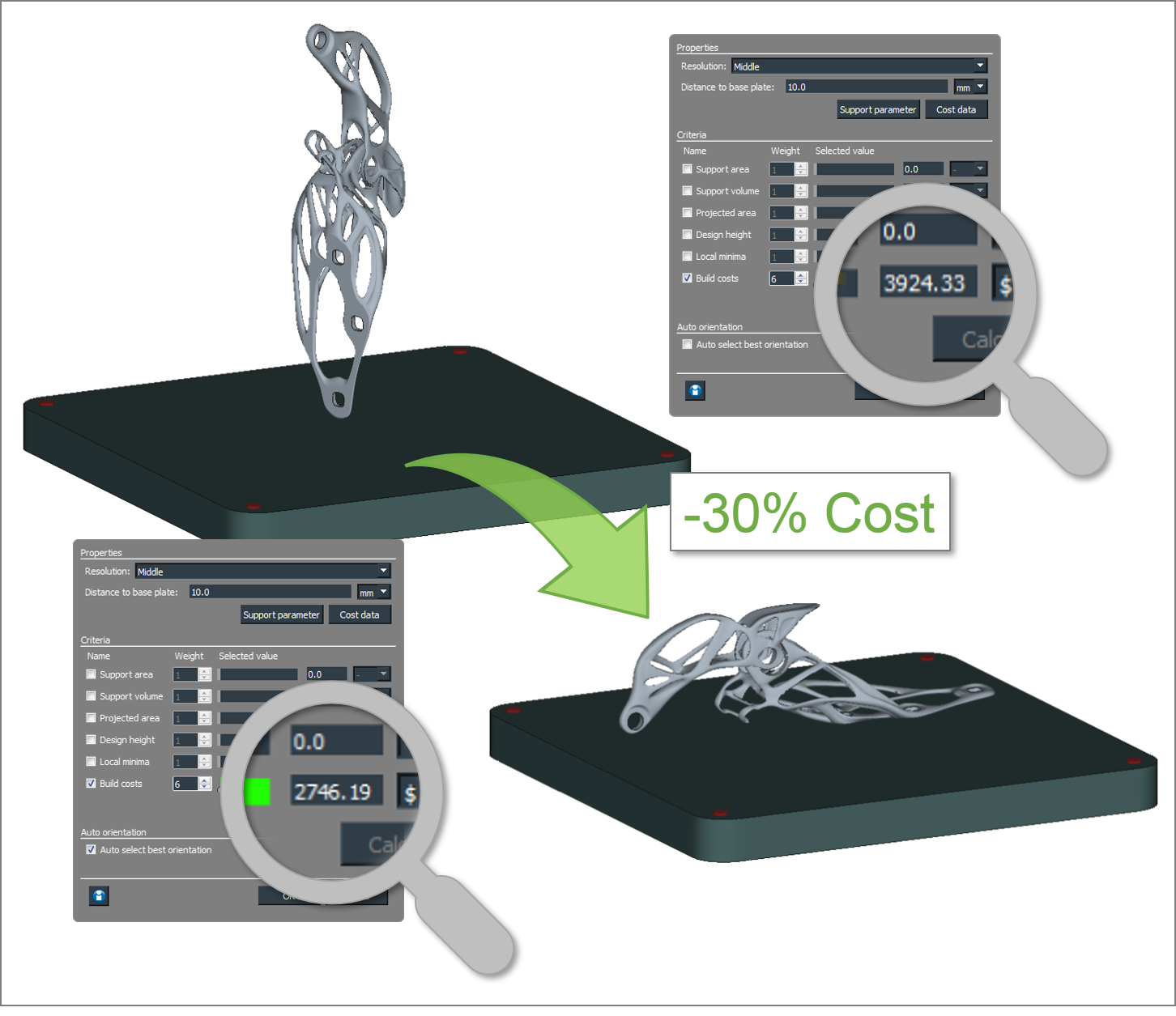

Simufact Additive 2020

California-based Simufact announced Simufact Additive 2020, its latest software solution for the optimization of metal-based additive manufacturing. Some of the new features include cost estimation of the build process, and improved interoperability with Materialise software and Renishaw 3D printers.

New hardware and 3D printers releases

Polyga, a Canadian developer of professional 3D scanning and mesh technologies, debuted a new affordable professional 3D scanner, known as HDI Compact S1. This system is reportedly capable of capturing high-resolution scan data of approximately 1.2 million points per scan with an accuracy of up to 40 microns (0.04 mm) in half a second.

GEWO 3D, a German manufacturer of high-temperature FFF/FDM 3D printers, presented its latest system, the GEWO Performer 260. As its name suggests, it maintains a build chamber temperature of 260°C and has a maximum nozzle temperature of 500°C. In addition, the GEWO Performer has a build volume of 70 liters and is able to print with travel speeds of up to 300 mm/s.

Based in Ankara, Turkey, Teknodizayn, a 3D printer manufacturer, began shipments of the industrial FFF/FDM 3D printer, LOOP PRO, through its brand LOOP 3D.

In addition to these releases, other notable 3D printers that made its debut at Formnext 2019 included:

–GE Additive‘s Arcam EBM Spectra L and Concept Laser M2 Series 5

–One Click Metal‘s MPrint

–Lumi Industries‘ Lumi³ (LumiCube)

-The Anisoprint ProM IS 500

-The ROBOZE ARGO 350

Also on Display

French additive manufacturing service provider Poly-Shape, an AddUp company, created a 72kg Francis turbine using Directed Energy Deposition – Power (DED-P). The part was showcased at Formnext to show the efficiency at which it was processes compared to one made from traditional manufacturing. According to Poly-Shape, the raw part can be produced without tooling in less than three days.

APWORKS showcased a 3D printed exhaust finisher which was made for a derivative of the Bugatti Chiron. Elsewhere, global chemicals producer SABIC displayed its materials developed in collaboration with ROBOZE and Stratasys. This includes EXTEM AMHH811F and ULTEM 9085 resin.

Coming from Australia, metal 3D printer manufacturer SPEE3D printed a 1.012kg copper sledgehammer in 10 minutes live in front of a crowd to demonstrate the capabilities of the SPEE3Dcell. Furthermore, Titomic, an Australian metal 3D printer manufacturer, unveiled the world’s largest additive manufactured Titanium part, a 5.5-meter rocket made in 27.6 hours using Titomic Kinetic Fusion.

Receive live news updates from the latest additive manufacturing events by subscribing to the 3D Printing Industry newsletter. Also, follow us on Twitter, and like us on Facebook.

Find talent for a project, or advance your career in 3D printing – join 3D Printing Jobs to apply and advertise.