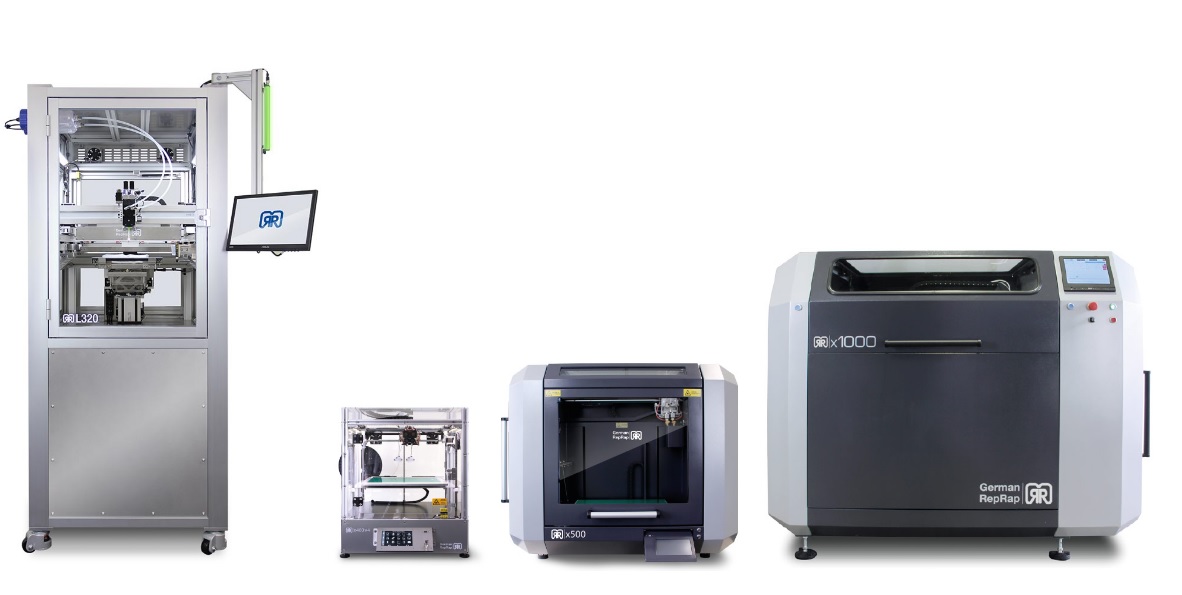

3D printer manufacturer German RepRap will introduce its new FFF/FDM and Liquid Additive Manufacturing (LAM) systems at Formnext 2019 this week.

The latest in the company’s X series, the x500pro 3D printer is designed for industrial environments and features a new Dual Lift Extruder System which enables automatic control. Conversely, the L320 is a LAM 3D printer capable of processing liquid silicone rubber.

The German RepRap x500pro

As stated by German RepRap, the x500pro is ideal for series production involving high-temperature, abrasive materials such as hardened steel. Unlike its predecessors, the X350Pro and X400, it features Direct Drive Material Handling which ensures an automatic, closed and transition-free material conveyance, even after a filament change.

The system also integrates a heated chamber, a feeder adapted to a material diameter of 1.75 mm and demonstrates water cooling capabilities. Filaments such as Hytrel 3D4000FL and 3D4100FL as well as PC, PP, and PEKK will be 3D printed live using the x500pro at the company’s booth located at Hall 11.1, Stand E71. These materials have been used in automotive, aerospace, electronics, research, textile and packaging applications.

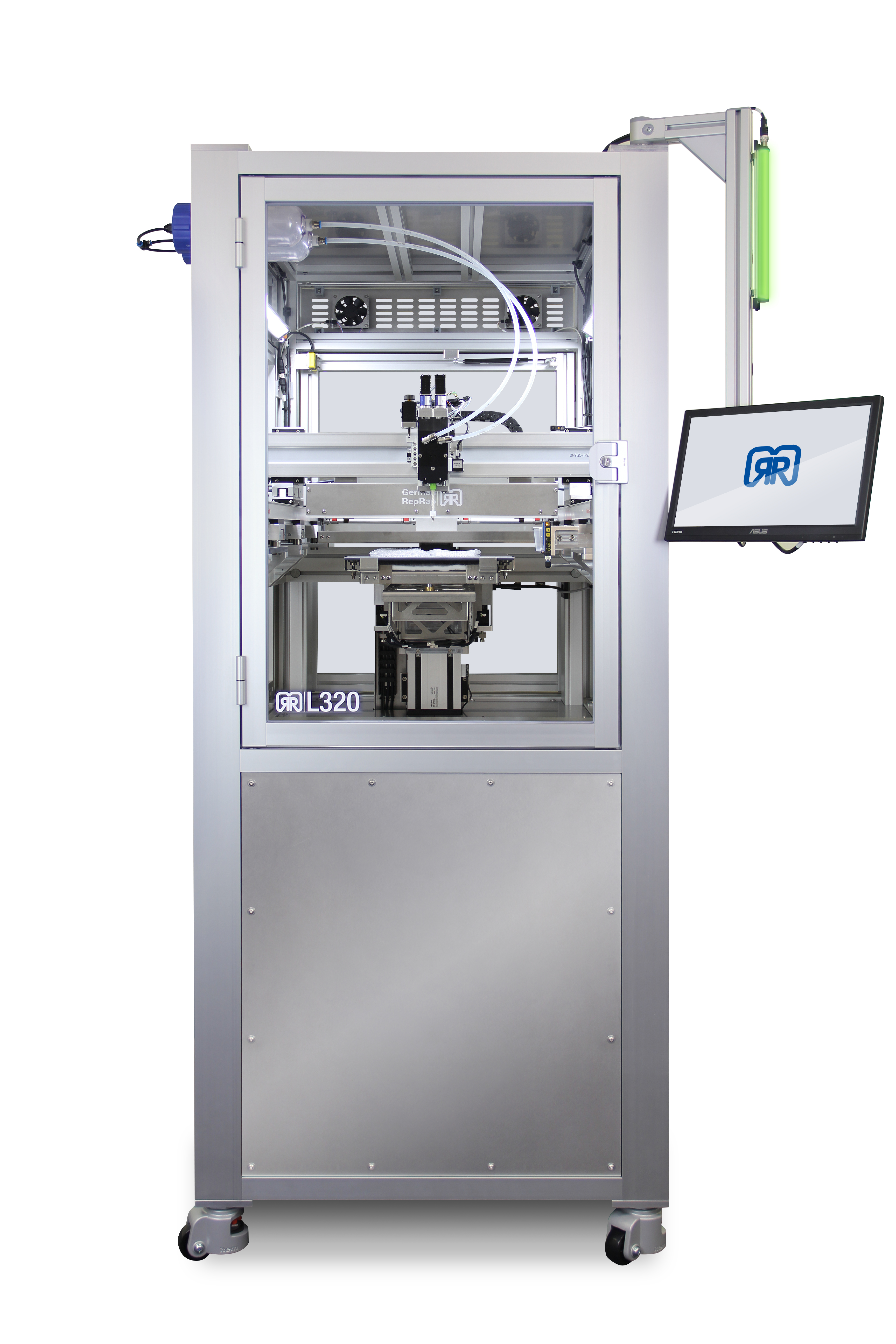

The L320

Making its debut, the L320, which was announced earlier this year, will demonstrate applications in the field of silicone elastomers. The system has a larger build volume than the German RepRap’s first LAM 3D printer, the L280. As opposed to FFF/FDM, LAM deposits liquid instead of filament which gets vulcanized into a solid object through exposure to a heat lamp that passes over the bed between layers.

Partnering with DSM, and Chromatic 3D Materials, German RepRap will also present a combination of FFF and LAM Technology through a “flexible and powerful solutions.” This intends to introduce flexible, high-performance materials such as polyurethane used within the automotive, rail and shoe industries.

Keep up with the latest news from Formnext by subscribing to the 3D Printing Industry newsletter. Also, follow us on Twitter and like us on Facebook. Seeking jobs in engineering? Make your profile on 3D Printing Jobs, or advertise to find experts in your area.

Featured image shows a Printhead on the L320 system. Photo via German RepRap