Formnext 2019 is now open. Spanning 4 floors of 2 halls at the Frankfurt Messe, more than 800 exhibitors are at the largest additive manufacturing show ever.

The 3D Printing Industry team is in Frankfurt for the week to ensure you don’t miss the latest news, and what better way to begin day one than a quick sprint through the show. We’ll be bringing you more detailed reports throughout the week, but for now, here’s the 3D Printing Industry first look at Formnext 2019.

Additive manufacturing systems at Formnext 2019

A brisk walk through the show quickly yields a selection of new industrial 3D printers from established companies, and offerings from enterprises that might be less well known.

Today we will be taking a closer look at Desktop Metal’s continuous carbon fiber 3D printer that was announced earlier this month. The pricing of the system, and it’s relatively low-cost subscription model, has generated a significant amount of discussion on the show floor.

Also likely to generate interest is a company called ProtoFab. Returning to Formnext for the second time, the CEO tells me they are the biggest 3D printing company in China working in production. ProtoFab has four locations across the country and has brought large-format SLA systems to the show. Interestingly, and this may prick the ears of 3D Systems, ProtoFab is showing a mock-up of their “Figure 4” manufacturing system aka F4.OM. An automated system of multiple 3D printing units and automatic processes mounted on a production line. Not to be confused with 3D Systems Figure 4.

Coherent continues to expand, the company has several metal additive systems on display including the CREATOR, CREATOR hybrid, they are joined by a powder cladding DED system. But the big news from the company is a significantly larger PBF system, the Infinity, which is a new direction for Coherent that opens up a much greater range of applications.

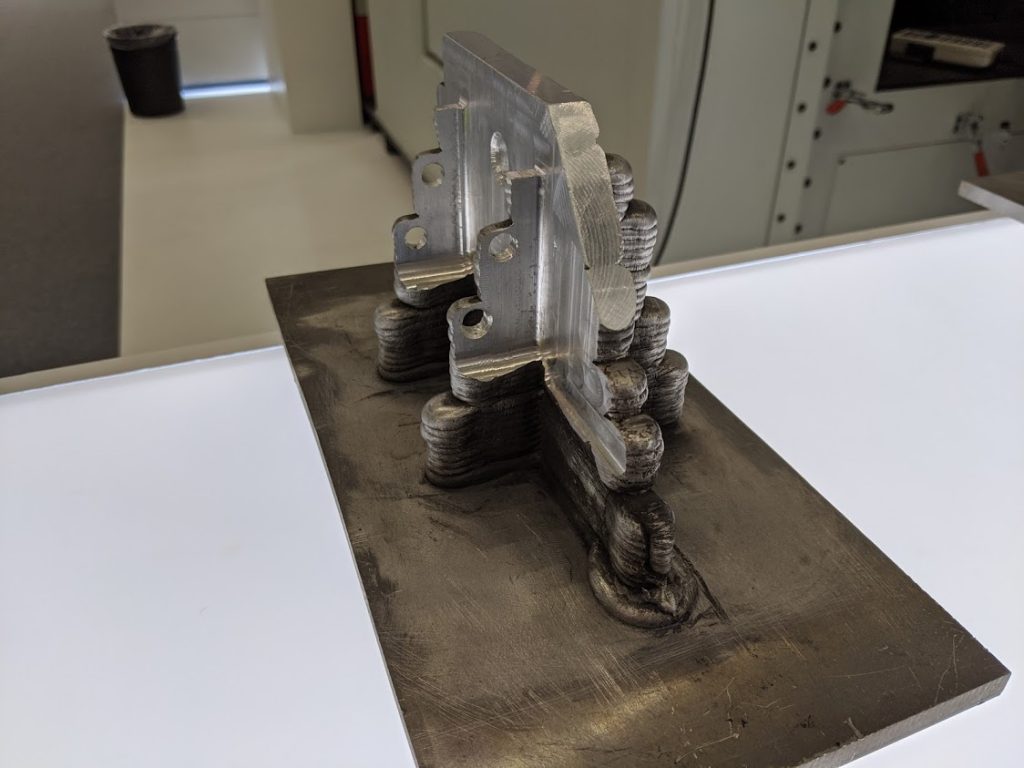

Addilan (12.0.B82) has a towering white rectangle at their booth. The Spanish company has developed a WAAM based metal 3D printer that uses a closed-loop control system and an inert chamber with a special loading and unloading system.

CEO Amagoia Paskual tells me the company was formed by 2 experienced machine tool manufacturers, with other 100 years of combined experience. Applications for the WAAM based system include rail, naval, oil and gas. The system is orientated for aerospace and uses titanium, while aluminum, inconel, and steels are also options.

Furthermore, it has a build volume of 1300 X 900 X 500 mm and can produce components weighing 300kgs, surprisingly this is one of the companies smaller machines.

Ermaksan might be another name unfamiliar to readers. The Turkish company can be found at 12.0. B122 with a series of metal powder bed fusion systems.

Tritone AM (12.0.B72) is a new company with a new additive metal and ceramic manufacturing system for the show. The company prints molds that are filled with either a ceramic or metal paste. The prefilled cartridges are designed to make operation safe and suitable for use in a wider range of environments. The company is based just outside Tel Aviv and has named the 3D printer Dominant.

The Dominant system has 6 stations that operate on a carousel Material, Mold, Inspection, Treatment, Heating, and Cooling. The technique is called Mold Jet and is intended to offer higher throughput. The company is new to additive but comes from the inkjet printing world and is bringing a deep expertise from this area.

ExOne (12.0.C21) is hard to miss and has the 25PRO on display for the first time at Formnext. The system has a 400x250x250mm build volume. The metal printer was first shown in Detroit as a prototype, the production version has several modifications and will begin shipping this quarter.

Xact Metal has further enhanced its metal additive systems, now an adaptive charge is possible and the systems can also work with a wider beam. Other new features include fast purge, dynamic spot size, layer image capture, and data logging. While the highly portable laser PBF systems made by the company are small, their expanded booth space at 12.0.C121 points to a company making increasingly bigger waves.

AddUp is hard to miss. They have metal additive systems including the Formup 700 & 200 systems plus DED from BeAM on the Modulo 250 and larger Modulo 400.

Multec M4 Metal system is an FDM based 3D printer with a desktop-sized footprint. It will be commercialized in Q1 2020 and is currently running BASF Ultrafuse material. The system will eventually have four nozzles so that running a ceramic material for supports will be possible.

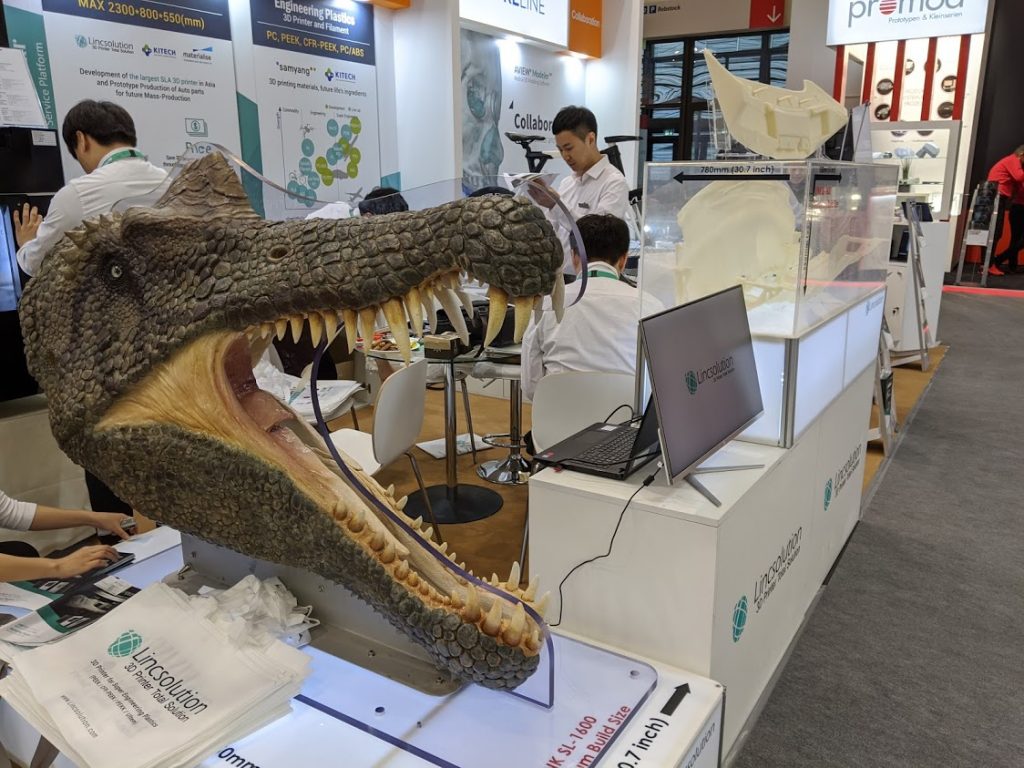

Korea has brought a selection of companies at the forefront of AM. Lincsolution (11.1.B11) and their SL-1600 have a particularly eye-catching display featuring a dinosaur head showing off the 1550 x 780 x 550mm build volume, the company’s SL-2300 boasts a 2300 x 800 x 550 build chamber.

Another company worth a closer look is InssTek. The company produces DMT metal AM systems. I remember InssTek from Formnext several years back sporting a small booth. Now the company has returned with a substantially larger exhibition space (11.0.E51).

Post-processing, 3D printing materials and software

As highlighted yesterday, DyeMansion will unveil the Powerfuse S at booth 11.1.D61 later today.

This year marks the appearance of a greater number of post-processing solutions, for example, Hiper 12.0.A121 offering a debinding and sintering service for metal binder jet and FDM processes. AMP+ (12.0.) has a large space dedicated to automated depowering for “industrial SLM”. Ossberger (12.0.C11) is demonstrating there depowering, infiltration, and drying system.

While not specifically post-processing, Sinterit is demonstrating how there SLS LISA system fits into a workflow with an interesting booth setup.

But my favorite booth so far belongs to Additive Manufacturing Technologies. Head to 12.1.E61 to see the Sheffield based company’s post-processing systems – but also to enjoy a selection of local beers served by a purpose-built robot.

There is an abundance of material companies at the show, in particular on the ground floor of hall 12. At 12.0.A132 PyroGenesis has there NEXTGEN powders, the company continues to add customers and is one of the few enterprises using plasma to make its powders.

Other powder producers are located nearby with Arcast (12.0.B135) who present custom-built atomizers and next door is Polema, a Russian metal powder manufacturer offering over 250 grades of powder, followed by Metalpine who promise “the art of spherical powder”.

We will be taking a closer look at the software tools at this year’s show, but in my first look, it is hard to ignore Autodesk – for what will become obvious reasons.

Autodesk has a novel clay printing process on display. Using the company’s Powermill and Netfabb technology and the Kolb machine near net shape models are 3D printed and then milled back to give the final model.

However, it is the full-size Motor Additive Manufactured Boat (MAMBO) that is impossible to miss here. At 6 meters and 800kg without motor, the boat was printed in sections using a print head mounted on Kuka robot arm, and then covered with fiberglass and painted.

The specific 3D printing system used was the Continuous Fiber Manufacturing (CFM) from Italian start-up Moi. The CFM system capable of printing continuous fiber and thermoset resin composites.

After Formnext the MAMBO will return to Italy for further work before taking to the water. Projects like the MAMBO, do seem to split opinion in the 3D printing industry. While many are impressed, others are vocal about the need to present dedicated industrial applications rather than proof of concept projects.

Anyway, for visitors needing a rest or wishing to ponder the type of designs the 3D printing industry should present at shows, Mitsubishi Chemical (12.1.B139) has a couple of 3D printed chair like structures on display. At least after this sprint through the four floors of Formnext they certainly look like chairs.

This brief run-through barely scratches the surface, so if you can’t make it to Frankfurt this week – then do the second best thing and follow our social media accounts on Twitter, Facebook, and LinkedIn.

Subscribe to the 3D Printing Industry newsletter for the latest news in additive manufacturing.

Looking for a career in additive manufacturing? Visit 3D Printing Jobs for a selection of roles in the industry.