Munich based 3D printing post-processing specialists, DyeMansion will launch a new system at formnext this week.

While the full details are not yet available until tomorrow’s official launch, 3D Printing Industry was able to find out a few exclusive details.

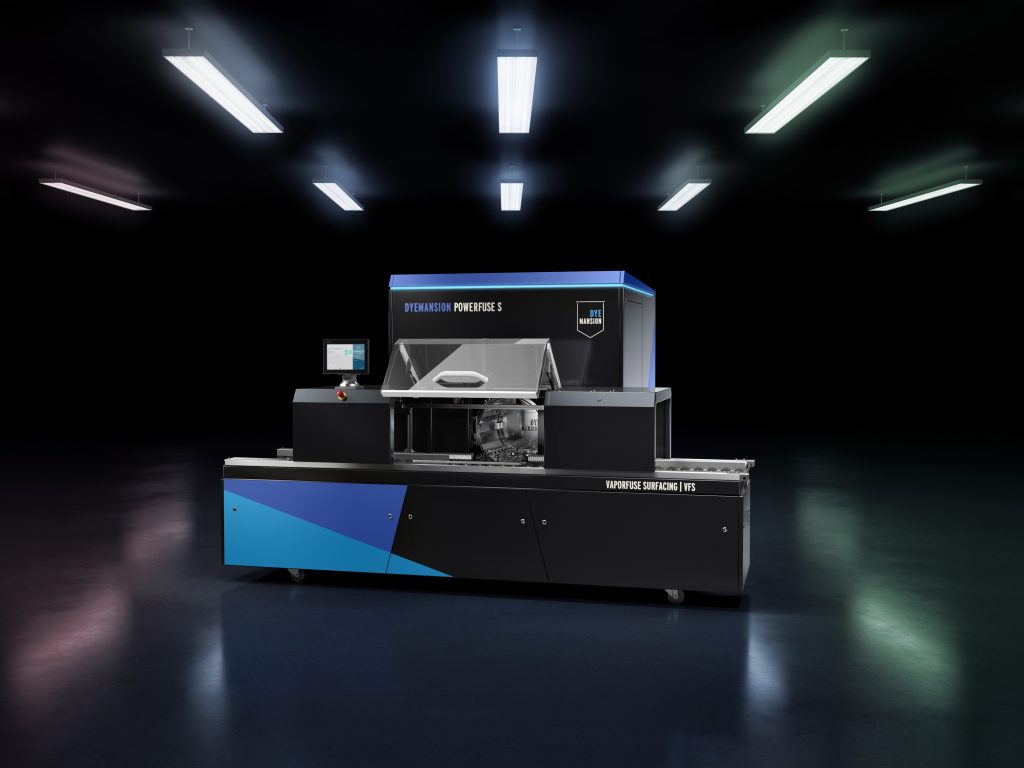

The latest addition to the DyeMansion range is the Powerfuse S, a post-processing system specifically designed for the additive manufacturing sector and described as, “the first chemical smoothing solution that proves to be really clean and industry-ready on the basis of obvious characteristics.”

Felix Ewald, CEO & co-founder at DyeMansion, said, “I am very proud of our team at DyeMansion for developing a system that will set new standards in the industry and impressively proves that our company is able to offer solutions at the highest industrial level.”

Post-processing with clean technology

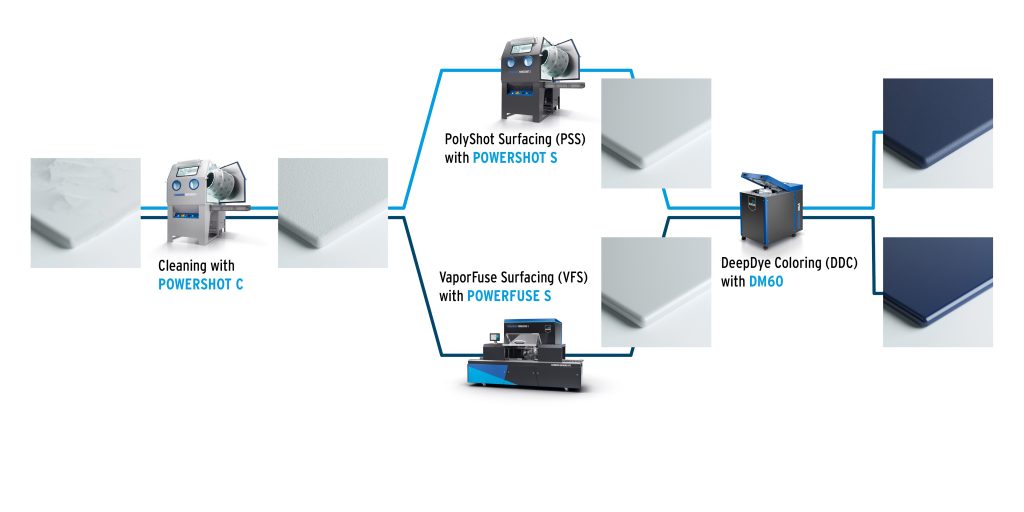

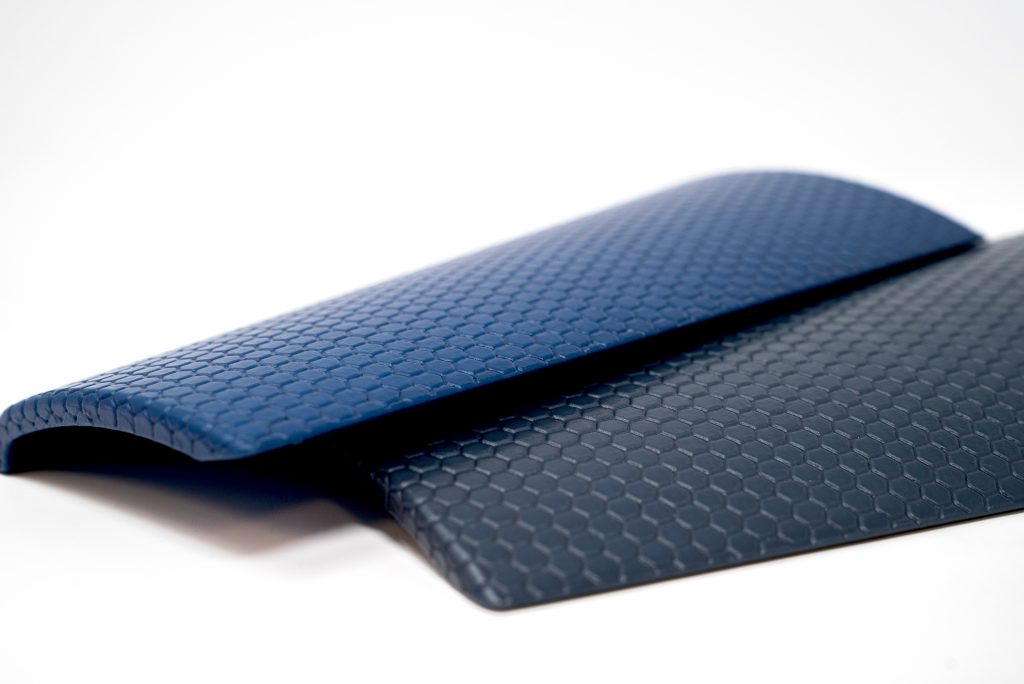

The Powerfuse S is the system behind DyeMansion’s proprietary VaporFuse Surfacing technology. It functions with an “Eco Fluid” solvent that conforms to EU regulation 10/2011, meaning they can be used for the processing of plastics that make contact with food.

DyeMansion highlights that this technology is differentiated from methods that use corrosive solvents or acids to achieve the required finish. The company says the “solvent is harmless and safe for the operator and environment” because “the solvent is circulated continuously in a closed loop and automatically recovered by the system.”

The Powerfuse S can be operated in a sustainable and contact-free process that does not result in chemical waste. The post-process system is branded as Industry 4.0 ready, with DyeMansion anticipating users will incorporate post-processing into advanced additive manufacturing workflows as end-users begin to operate the technology at greater scales.

Features to ensure the Powerfuse S is suitable for such an environment include fully automatic loading options, connectivity, and batch tracking features. DyeMansion has developed pre-loaded programs for common materials and the Powerfuse S process parameters can be modified for bespoke applications. The system is designed for “seamless integration with existing production processes such as the DyeMansion Print-to-Product workflow,” according to the company.

Although full technical specifications will not be available until Tuesday when a technical whitepaper is released, we understand the key details to be as follows:

Powerfuse S technical specifications

Process chamber volume: 129 litres

Cycle time: 40-80 minutes (Varies with material)

Basket dimensions: 610mm x 340mm x 315mm (L x W x H)

Technology compatibility: SLS, MJF, HSS, FDM/FFF

Material compatibility: PA11, PA12, TPU, ULTEM (Beta), others on request

Visitors to formnext 2019 can get their first look at the DyeMansion Powerfuse S on Tuesday, November 19th at 1:45pm. The DyeMansion management board will also provide a company update, info on technology developments and be available for a Q&A session at booth 11.1, D61 after the unveiling of the Powerfuse S.

The 3D Printing Industry team is back in Frankfurt for formnext this week. Get in touch if you’d like to meet. If you can’t attend the show, then follow our social media accounts on Twitter, Facebook, and LinkedIn.

Subscribe to the 3D Printing Industry newsletter for the latest news in additive manufacturing.

Looking for a career in additive manufacturing? Visit 3D Printing Jobs for a selection of roles in the industry.

The DyeMansion the Powerfuse S post-processing system. Image via DyeMansion.