Italian 3D printer manufacturer ROBOZE is showcasing its latest industrial additive manufacturing system, the ARGO 350, at Formnext 2019 this week. The company is also displaying its materials portfolio in tandem with the announcement of a partnership with Belgian chemical company Solvay

“Our presence at Formnext will give us the chance to showcase our new 3D printing solutions to the global manufacturing market,” stated Alessio Lorusso, Roboze CEO & Founder.

“The innovations we will showcase address the needs of all those entrepreneurial realities aiming at increasing their productivity thanks to high-temperature super polymers and composite materials for the production of finished parts with the highest precision.”

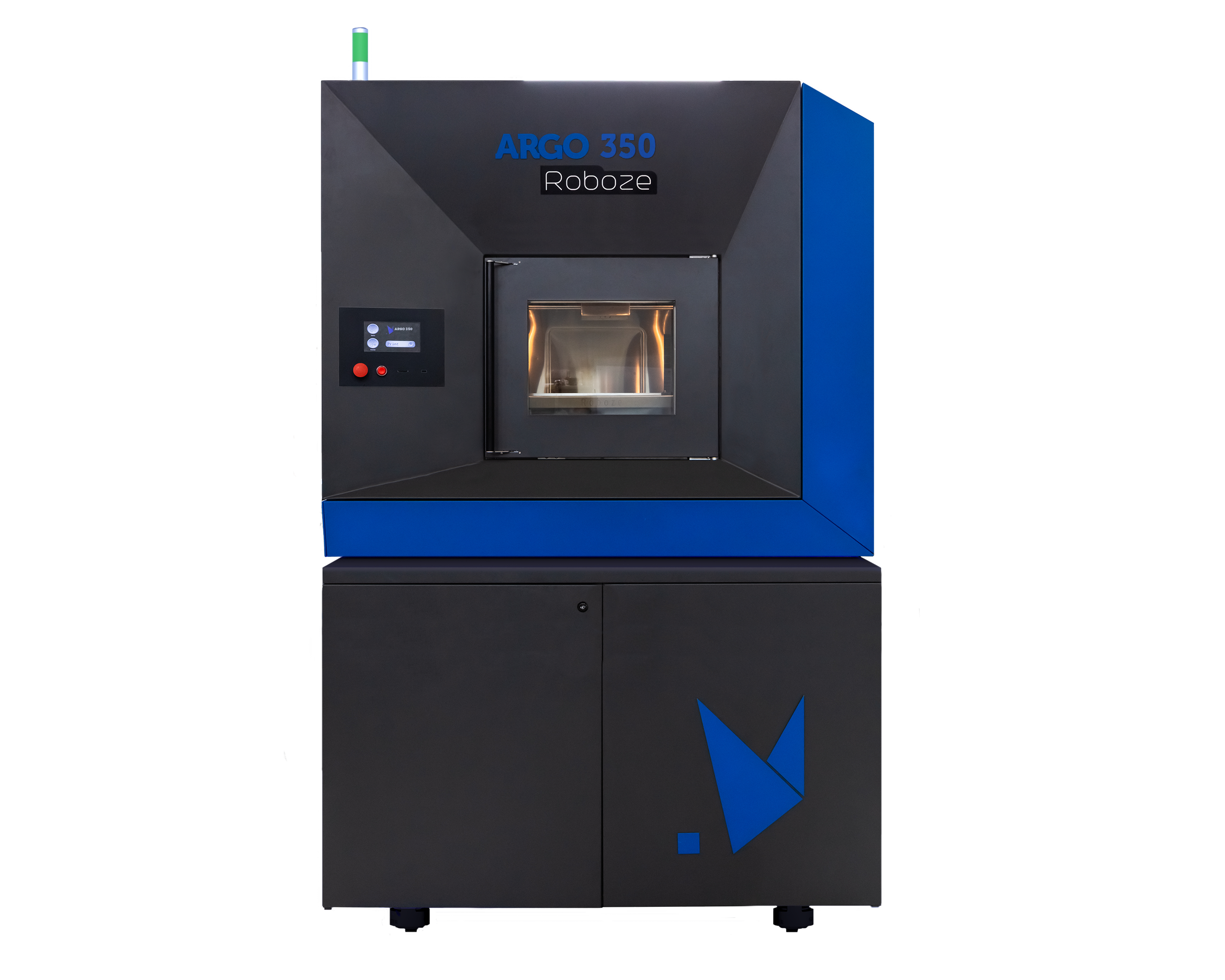

The ARGO 350

With a build plate measuring 350x300x300mm, the ARGO 350 is a more compact version of the ARGO 500. It incorporates a double gear system to better dissipate heat, reduce wear phenomena, increase the strength of the feeding system and optimize pressure on the filament. Furthermore, it enables more complex parts as a result of the use of soluble and breakaway support materials.

The ARGO 350 also holds an HVP Extruder, which is designed to reach 450°C for the extrusion of composite and high-temperature materials. Similar to ARGO 500, the ARGO 350’s Beltless System has a positioning precision of 10 microns to assure continuous movement repeatability. In addition, its build plate has an automatic leveling system that increases the repeatability of the parts produced in different cycles.

Moreover, a controlled heated chamber, reaching a maximum temperature of 180°C, allows the 3D printer to minimize the thermal shock of extruded materials. This cools it down at a slower pace to lessen the mechanical stress and any residual tension from thermal treatments.

ROBOZE accelerates material development

ROBOZE’s latest partnership with Solvay, which follows its collaboration with SABIC to create EXTEM™ AMHH811F, a new amorphous thermoplastic polyimide filament, will seek to increase the production of 3D printed end-use parts rivaling metal.

The new agreement will offer KetaSpire® PEEK SOLVAY powered by ROBOZE and KetaSpire® Carbon PEEK SOLVAY powered by ROBOZE, now exclusively available for ROBOZE ARGO solutions. As stated by the company, ROBOZE’s Production 3D printers will be the set standard platform for the creation of components using Solvay ultra-polymers.

The price of the ARGO 350 has yet to be disclosed. Formnext visitors can see the ROBOZE 3D printers, innovations, and materials at Hall 12.1, Booth C61.

For all of the latest 3D printing news from Formnext 2019, subscribe to the 3D Printing Industry newsletter, follow us on Twitter, and like us on Facebook.

Find talent for a project, or advance your career in 3D printing – join 3D Printing Jobs to apply and advertise.

Featured image shows the ARGO 350 3D printer. Photo via ROBOZE.