You would be forgiven for being skeptical of a technology that claims to harness all the benefits of SLA, DLP, and LCD 3D printing in a single machine, however that is exactly what new start-up AXTRA3D has achieved with its new Hybrid PhotoSynthesis (HPS) technology.

Unveiled at Formnext 2021, the HPS platform takes the surface quality and scalability benefits of SLA and combines this with the speed of an LCD system to produce isotropic parts. To achieve this, HPS enables DLP and SLA to work at the same time, on the same wavelength, with the same energy.

The technology powers AXTRA3D’s first 3D printer, Lumia, which the company says will transform photopolymer 3D printing for applications in sectors such as healthcare, industrial manufacturing, design, automotive, aerospace, and functional prototyping.

“HPS brilliantly coalesces the energy from two light sources, DLP & Laser, creating a harmonized light engine that efficiently harnesses the power from the two sources,” said Praveen Tummula, Chief Operations, and Business Officer and Co-founder of AXTRA3D.

How HPS Technology works

Although a newcomer to the show, AXTRA3D is led by an experienced executive team. The start-up’s Founder, CEO, and CTO, Gianni Zitelli, previously developed the technology used by high-speed resin 3D printer manufacturer Nexa3D.

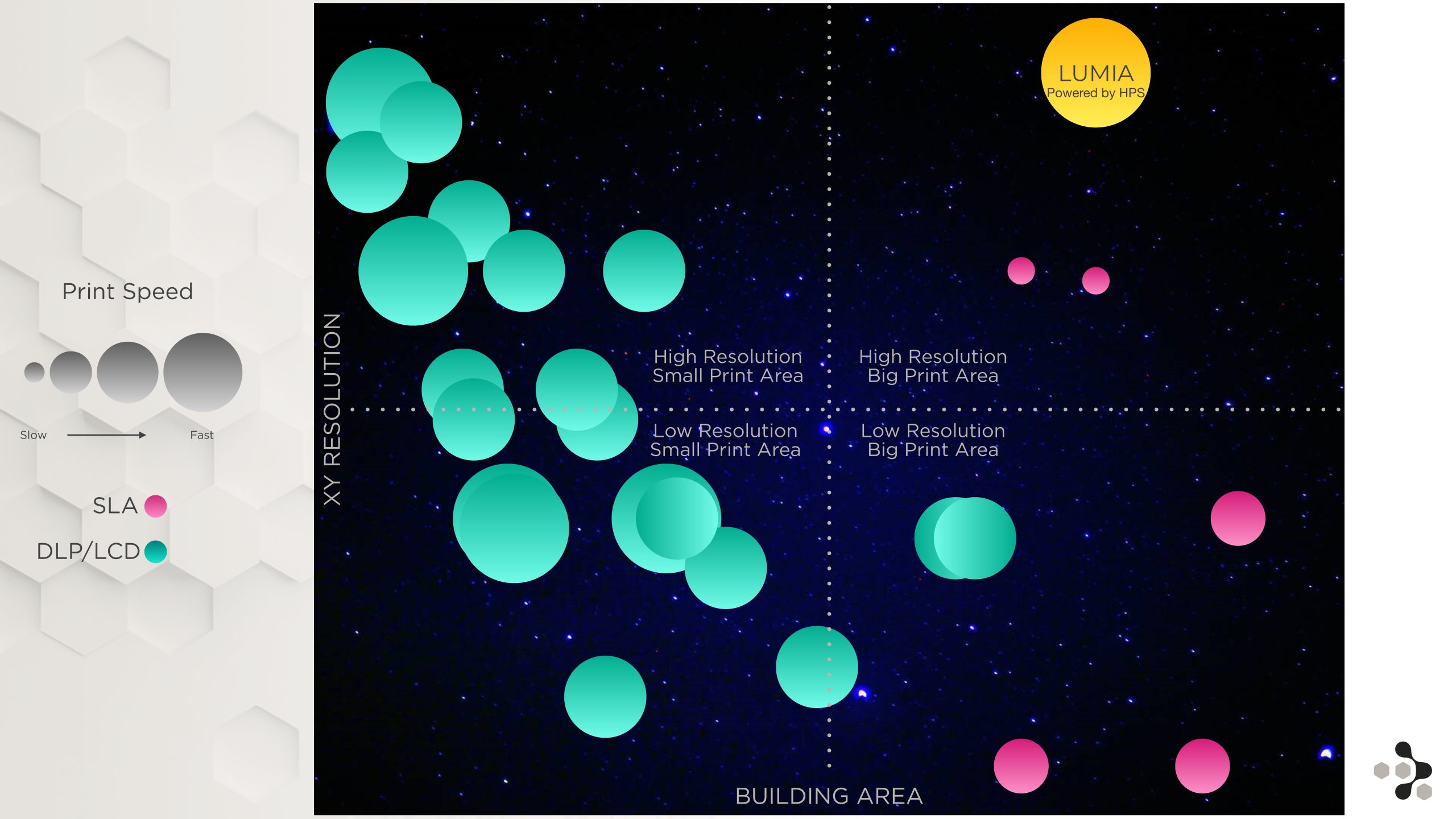

The AXTRA3D team had long identified that within photopolymer 3D printing, customers typically have to choose between SLA and DLP or LCD 3D printing technologies, which ultimately results in tradeoffs between print speed and resolution, or print area and surface quality.

The company is removing these tradeoffs via its patented HPS technology, which it developed in just six months, Zitelli told me. Although headquartered in the US, AXTRA3D’s entire R&D team is based in Italy.

According to him, HPS surpasses the resolution of DLP and LCD technologies while offering the print area of industrial-grade SLA processes. The patented technology combines the superiority of a laser with the capabilities of a projector.

HPS is also capable of printing at the speed of DLP and LCD while matching the surface quality of SLA. The light engine reportedly outperforms other 3D printing technologies by offering a superior mirror-finish surface quality without any aliasing or stair-stepping surface defects thanks to its laser-edge technology. HPS also removes the need for post-print refinishing.

The Lumia 3D printer

The first and only 3D printer powered by HPS technology is AXTRA3D’s Lumia machine, which prints at a speed of 18cm per hour on the Z-axis. In addition to HPS, the printer features a number of AXTRA3D’s other patented technologies, including its Fast and Easy Peeling Technology, Zero Suction Effect Technology, and Non-Degenerative Vat Membrane Technology.

Powered by HPS technology, the Lumia printer is suited to a wide range of applications. One such application that has proven the technology’s capabilities is dental aligners. Via HPS, the printing time was five minutes per part, the same speed as the same aligner printed using a DLP technique and considerably faster than one printed using SLA (85 minutes).

While the HPS printed aligner was produced in the same time as the DLP printed aligner, it matched the resolution and surface quality of the SLA printed aligner, which are key to ensuring the aligner is precisely customized for the patient and comfortable to wear.

The technical specifications for the Lumia are as follows:

| Build volume | X – 265 mm/10.4 inches Y – 150 mm/5.9 inches Z – 600 mm/23.6 inches Volume 24 liters |

| XY resolution | 40 microns |

| Light Engine Technology | Hybrid PhotoSynthesis (HPS) |

| Resin-membrane interface technologies | Fast and Easy Peeling Technology Zero Suction Effect Technology Non-Degenerative Vat Membrane Technology Unlimited Cross-Section Printing Technology |

| Printing speed | Independent of the XY print area Up to 9 mm/min or 0.35 in/min 90 minute print time for the entire volume (print speed varies with material and layer thickness) |

Subscribe to the 3D Printing Industry newsletter for the latest news in additive manufacturing. You can also stay connected by following us on Twitter and liking us on Facebook.

Looking for a career in additive manufacturing? Visit 3D Printing Jobs for a selection of roles in the industry.

Subscribe to our YouTube channel for the latest 3D printing video shorts, reviews and webinar replays.

Featured image shows the Lumia 3D printer. Photo via AXTRA3D.